Installation Temperature: The installation temperature should be over 0℃. If the ambient temperature is lower than 0℃, the cable should be preheated.

Operating Temperature: Max permissible continuous operating temperature of the conductor shall not exceed 90℃.

Conductor Short-circuit Temperature: Max temperature at short-circuit shall not exceed 250℃ . The short-circuit duration shall not exceed 5 seconds.

Bending Radius: 20( d+D) +/-5% for single core cable,15( d+D )+/-5% for multi-core cable.

D=Actual outer diameter of cable (mm),d=Actual diameter of the conductor (mm)

Standard: IEC60502, GB/T12706, or other standard required by the customer. The requirements for flame retardant property are according to IEC60332-3 and GB18380.

Packing: Steel/wooden reel, wooden reel, or steel reel.

|

Description |

Application |

|

Cu or Al conductor/ XLPE insulated/ PVC sheathed power cable |

It is installed in indoor or outdoor,and can be pulled with a proper force during installation ,but unable to bear external mechanical force.Single core cable is not permitted to install in magnetic duct. |

|

Cu or Al conductor/ XLPE insulated/ PVC sheathed flame retardant power cable |

|

|

Cu or Al conductor/ XLPE insulated/ steel tape armored/ PVC sheathed power cable |

It is installed under ground and able to bear external mechanical force,but unable to bear large pulling force. |

|

Cu or Al conductor/ XLPE insulated steel tape armored/ PVC sheathed flame retardant power cable |

|

|

Cu or Al conductor/ XLPE insulated/ steel wire armored/ PVC sheathed power cable |

It is installed under water or where the cable route is with large difference of level.It is able to bear external mechanical force and proper pulling force. |

|

Cu or Al conductor/ XLPE insulated/ steel wire armored/ PVC sheathed flame retardant power cable |

|

Type |

No of Cores |

Rated Voltage (kV) |

||||||

|

0.6/1 |

3.6/6 |

6/6 6/10 |

8.7/10 8.7/15 |

12/20 |

21/35 |

26/35 26/45 |

||

|

Nominal Area of Conductor (sq.mm) |

||||||||

|

CU or AL/XLPE/PVC |

1 |

1.5 to 240 |

25 to 500 |

25 to 500 |

25 to 500 |

35 to 500 |

50 to 500 |

50 to 500 |

|

3 |

1.5 to 240 |

25 to 300 |

25 to 300 |

25 to 300 |

35 to 300 |

--- |

--- |

|

|

CU or AL/XLPE/STA/PVC |

3 |

10 to 240 |

25 to 300 |

25 to 300 |

25 to 300 |

35 to 300 |

--- |

--- |

|

CU or AL/XLPE/SWA/PVC |

3 |

10 to 240 |

25 to 300 |

25 to 300 |

25 to 300 |

35 to 300 |

--- |

--- |

*1kV 4-core XLPE cable is also in our supply range.

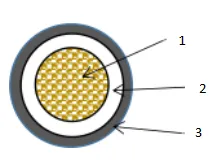

Construction of 0.6/1 kV 1-core

CU or AL/XLPE Insulated/ PVC Sheathed Power Cable

|

No |

Construction and materials |

|

1 |

Copper or aluminum conductor |

|

2 |

XLPE insulation |

|

3 |

Non-flame retardant or flame retardant PVC sheath |

Technical Characteristics of 0.6/1kV for CU or AL conductor/XLPE Insulated/PVC Sheathed Power Cable, 1-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

1x 1.5 |

0.7 |

1.5 |

6 |

12.1 |

--- |

53 |

--- |

|

1x2.5 |

0.7 |

1.5 |

6 |

7.41 |

12.1 |

68 |

53 |

|

1x4 |

0.7 |

1.5 |

7 |

4.61 |

7.41 |

87 |

64 |

|

1x6 |

0.7 |

1.5 |

7 |

3.08 |

4.61 |

110 |

73 |

|

1x10 |

0.7 |

1.5 |

8 |

1.83 |

3.08 |

155 |

95 |

|

1x16 |

0.7 |

1.5 |

9 |

1.15 |

1.91 |

220 |

120 |

|

1x25 |

0.9 |

1.5 |

10 |

0.727 |

1.20 |

345 |

190 |

|

1x35 |

0.9 |

1.5 |

12 |

0.524 |

0.868 |

424 |

207 |

|

1x50 |

1.0 |

1.5 |

13 |

0.387 |

0.641 |

555 |

245 |

|

1x70 |

1.1 |

1.5 |

14 |

0.268 |

0.443 |

770 |

336 |

|

1x95 |

1.1 |

1.5 |

16 |

0.193 |

0.320 |

1040 |

455 |

|

1x 120 |

1.2 |

1.5 |

18 |

0.153 |

0.253 |

1290 |

550 |

|

1x 150 |

1.4 |

2.0 |

21 |

0.124 |

0.206 |

1590 |

650 |

|

1x 185 |

1.6 |

2.0 |

23 |

0.0991 |

0.164 |

1944 |

804 |

|

1x240 |

1.7 |

2.0 |

25 |

0.0754 |

0.125 |

2510 |

1021 |

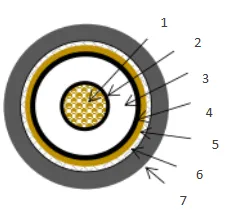

Construction of 3.6/6kV to 26/35kV, 1- core, CU or AL conductor/XLPE Insulated/ PVC Sheathed Power Cable

|

No |

Construction and materials |

|

1 |

Copper or aluminum conductor |

|

2 |

Semi-conductive conductor screen |

|

3 |

XLPE insulation |

|

4 |

Semi-conductive insulation screen |

|

5 |

Copper tape screen |

|

6 |

Non-woven cloth tape or glass fiber tape |

|

7 |

Non-flame retardant or flame retardant PVC sheath |

Technical Characteristics of 3.6/6kV for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 1-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

1x25 |

2.5 |

1.5 |

19 |

0.727 |

1.20 |

576 |

421 |

|

1x35 |

2.5 |

1.5 |

20 |

0.524 |

0.868 |

695 |

479 |

|

1x50 |

2.5 |

2.0 |

21 |

0.387 |

0.641 |

860 |

550 |

|

1x70 |

2.5 |

2.0 |

23 |

0.268 |

0.443 |

1081 |

648 |

|

1x95 |

2.5 |

2.0 |

24 |

0.193 |

0.320 |

1350 |

762 |

|

1x 120 |

2.5 |

2.0 |

26 |

0.153 |

0.253 |

1640 |

897 |

|

1x 150 |

2.5 |

2.0 |

27 |

0.124 |

0.206 |

1947 |

1079 |

|

1x 185 |

2.5 |

2.0 |

29 |

0.0991 |

0.164 |

2302 |

1156 |

|

1x240 |

2.6 |

2.0 |

32 |

0.0754 |

0.125 |

2886 |

1400 |

|

1x300 |

2.8 |

2.0 |

34 |

0.0601 |

0.100 |

3483 |

1626 |

|

1x400 |

3.0 |

2.5 |

38 |

0.047 |

0.0778 |

4477 |

2001 |

|

1x500 |

3.2 |

2.5 |

41 |

0.0366 |

0.0605 |

5452 |

2357 |

Technical Characteristics of 6/6kV,6/10kV for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 1-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diamete (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

1x25 |

3.4 |

2.0 |

20 |

0.727 |

1.20 |

598 |

443 |

|

1x35 |

3.4 |

2.0 |

22 |

0.524 |

0.868 |

719 |

502 |

|

1x50 |

3.4 |

2.0 |

23 |

0.387 |

0.641 |

884 |

575 |

|

1x70 |

3.4 |

2.0 |

24 |

0.268 |

0.443 |

1097 |

664 |

|

1x95 |

3.4 |

2.0 |

26 |

0.193 |

0.320 |

1378 |

790 |

|

1x 120 |

3.4 |

2.0 |

28 |

0.153 |

0.253 |

1658 |

916 |

|

1x 150 |

3.4 |

2.0 |

30 |

0.124 |

0.206 |

1967 |

1038 |

|

1x 185 |

3.4 |

2.0 |

31 |

0.0991 |

0.164 |

2335 |

1190 |

|

1x240 |

3.4 |

2.0 |

34 |

0.0754 |

0.125 |

2908 |

1423 |

|

1x300 |

3.4 |

2.0 |

36 |

0.0601 |

0.100 |

3507 |

1650 |

|

1x400 |

3.4 |

2.5 |

39 |

0.0470 |

0.0778 |

4503 |

2027 |

|

1x500 |

3.4 |

2.5 |

42 |

0.0366 |

0.0605 |

5479 |

2384 |

Technical Characteristics of 8.7/10kV,8.7/15kV for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 1-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

1x25 |

4.5 |

1.8 |

23 |

0.727 |

1.20 |

680 |

525 |

|

1x35 |

4.5 |

1.8 |

24 |

0.524 |

0.868 |

804 |

587 |

|

1x50 |

4.5 |

1.9 |

25 |

0.387 |

0.641 |

984 |

674 |

|

1x70 |

4.5 |

1.9 |

27 |

0.268 |

0.443 |

1201 |

768 |

|

1x95 |

4.5 |

2.0 |

29 |

0.193 |

0.320 |

1490 |

902 |

|

1x 120 |

4.5 |

2.0 |

30 |

0.153 |

0.253 |

1765 |

1022 |

|

1x 150 |

4.5 |

2.1 |

32 |

0.124 |

0.206 |

2091 |

1162 |

|

1x 185 |

4.5 |

2.1 |

34 |

0.0991 |

0.164 |

2452 |

1307 |

|

1x240 |

4.5 |

2.2 |

36 |

0.0754 |

0.125 |

3034 |

1548 |

|

1x300 |

4.5 |

2.4 |

39 |

0.0601 |

0.100 |

3672 |

1815 |

|

1x400 |

4.5 |

2.4 |

42 |

0.047 |

0.0778 |

4646 |

2170 |

|

1x500 |

4.5 |

2.5 |

45 |

0.0366 |

0.0605 |

5651 |

2556 |

Technical Characteristics of 12/20kVfor CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 1-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

1x35 |

5.5 |

2.0 |

27 |

0.524 |

0.868 |

979 |

762 |

|

1x50 |

5.5 |

2.0 |

29 |

0.387 |

0.641 |

1155 |

846 |

|

1x70 |

5.5 |

2.0 |

30 |

0.268 |

0.443 |

1393 |

959 |

|

1x95 |

5.5 |

2.0 |

32 |

0.193 |

0.320 |

1681 |

1093 |

|

1x 120 |

5.5 |

2.0 |

34 |

0.153 |

0.253 |

1979 |

1236 |

|

1x 150 |

5.5 |

2.0 |

35 |

0.124 |

0.206 |

2301 |

1373 |

|

1x 185 |

5.5 |

2.0 |

38 |

0.0991 |

0.164 |

2718 |

1573 |

|

1x240 |

5.5 |

2.5 |

40 |

0.0754 |

0.125 |

3302 |

1817 |

|

1x300 |

5.5 |

2.5 |

43 |

0.0601 |

0.100 |

3941 |

2084 |

|

1x400 |

5.5 |

2.5 |

45 |

0.0470 |

0.0778 |

4931 |

2455 |

|

1x500 |

5.5 |

2.5 |

48 |

0.0366 |

0.0605 |

5956 |

2861 |

Technical Characteristics of 21/35kVfor CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 1-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

1x50 |

9.3 |

2.0 |

37 |

0.387 |

0.641 |

1609 |

1360 |

|

1x70 |

9.3 |

2.5 |

38 |

0.268 |

0.443 |

1850 |

1417 |

|

1x95 |

9.3 |

2.5 |

40 |

0.193 |

0.320 |

2193 |

1605 |

|

1x 120 |

9.3 |

2.5 |

42 |

0.153 |

0.253 |

2498 |

1756 |

|

1x 150 |

9.3 |

2.5 |

44 |

0.124 |

0.206 |

2839 |

1910 |

|

1x 185 |

9.3 |

2.5 |

45 |

0.0991 |

0.164 |

3248 |

2102 |

|

1x240 |

9.3 |

2.5 |

48 |

0.0754 |

0.125 |

3881 |

2395 |

|

1x300 |

9.3 |

3.0 |

50 |

0.0601 |

0.100 |

4529 |

2672 |

|

1x400 |

9.3 |

3.0 |

53 |

0.0470 |

0.0778 |

5570 |

3094 |

|

1x500 |

9.3 |

3.0 |

55 |

0.0366 |

0.0605 |

6690 |

3595 |

Technical Characteristics of 26/35kV,26/35kV for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 1-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

1x50 |

10.5 |

2.2 |

39 |

0.387 |

0.641 |

1758 |

1449 |

|

1x70 |

10.5 |

2.4 |

41 |

0.268 |

0.443 |

2035 |

1604 |

|

1x95 |

10.5 |

2.4 |

43 |

0.193 |

0.320 |

2355 |

1767 |

|

1x 120 |

10.5 |

2.4 |

44 |

0.153 |

0.253 |

2666 |

1923 |

|

1x 150 |

10.5 |

2.5 |

46 |

0.124 |

0.206 |

3031 |

2103 |

|

1x 185 |

10.5 |

2.5 |

48 |

0.0991 |

0.164 |

3427 |

2282 |

|

1x240 |

10.5 |

2.6 |

50 |

0.0754 |

0.125 |

4070 |

2584 |

|

1x300 |

10.5 |

2.7 |

53 |

0.0601 |

0.100 |

4748 |

2891 |

|

1x400 |

10.5 |

2.8 |

56 |

0.0470 |

0.0778 |

5801 |

3325 |

|

1x500 |

10.5 |

2.9 |

59 |

0.0366 |

0.0605 |

6623 |

4076 |

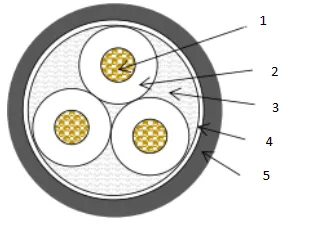

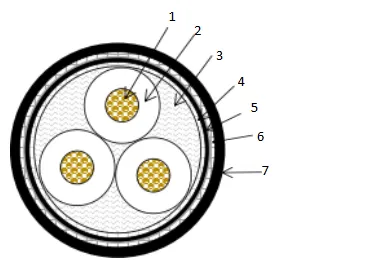

Construction of 0.6/1kV 3-core for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable

|

No |

Construction and materials |

|

1 |

Copper or aluminum conductor |

|

2 |

XLPE insulation |

|

3 |

PP yarn or glass fiber rope filler |

|

4 |

Non-woven cloth tape or glass fiber tape |

|

5 |

Non-flame retardant or flame retardant PVC outer sheath |

Technical Characteristics of 0.6/1kV for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 3-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x 1.5 |

0.7 |

1.5 |

10 |

12.1 |

--- |

145 |

--- |

|

3x2.5 |

0.7 |

1.5 |

11 |

7.41 |

12.1 |

185 |

140 |

|

3x4 |

0.7 |

1.5 |

12 |

4.61 |

7.41 |

250 |

175 |

|

3x6 |

0.7 |

1.5 |

13 |

3.08 |

4.61 |

320 |

210 |

|

3x10 |

0.7 |

1.5 |

15 |

1.83 |

3.08 |

450 |

260 |

|

3x16 |

0.7 |

1.5 |

17 |

1.15 |

1.91 |

640 |

340 |

|

3x25 |

0.9 |

2.0 |

21 |

0.727 |

1.20 |

940 |

470 |

|

3x35 |

0.9 |

2.0 |

23 |

0.524 |

0.868 |

1260 |

600 |

|

3x50 |

1.0 |

2.0 |

27 |

0.387 |

0.641 |

1670 |

730 |

|

3x70 |

1.1 |

2.0 |

30 |

0.268 |

0.443 |

2280 |

970 |

|

3x95 |

1.1 |

2.0 |

34 |

0.193 |

0.320 |

3020 |

1240 |

|

3x 120 |

1.2 |

2.5 |

38 |

0.153 |

0.253 |

3790 |

1540 |

|

3x 150 |

1.4 |

2.5 |

42 |

0.124 |

0.206 |

4750 |

1940 |

|

3x 185 |

1.6 |

2.5 |

45 |

0.0991 |

0.164 |

5654 |

2248 |

|

3x240 |

1.7 |

3.0 |

51 |

0.0754 |

0.125 |

7243 |

2723 |

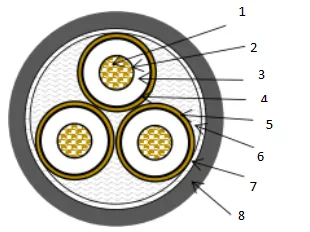

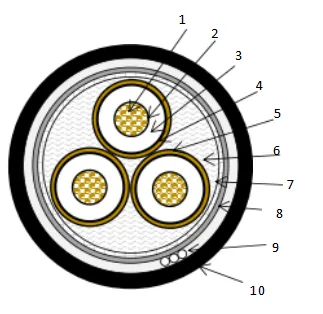

Construction of 3.6/6kV to 26/35kV 3-core for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable

|

No |

Construction and materials |

|

1 |

Copper or aluminum conductor |

|

2 |

Semi-conductive conductor screen |

|

3 |

XLPE insulation |

|

4 |

Semi-conductive insulation screen |

|

5 |

Copper tape screen |

|

6 |

PP yarn or glass fiber rope filler |

|

7 |

Non-woven cloth tape or glass fiber tape |

|

8 |

Non-flame retardant or flame retardant PVC outer sheath |

Technical Characteristics of 3.6/6kV for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 3-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x25 |

2.5 |

2.5 |

40 |

0.727 |

1.20 |

576 |

421 |

|

3x35 |

2.5 |

2.5 |

43 |

0.524 |

0.868 |

695 |

479 |

|

3x50 |

2.5 |

2.5 |

46 |

0.387 |

0.641 |

850 |

550 |

|

3x70 |

2.5 |

2.5 |

49 |

0.268 |

0.443 |

1081 |

648 |

|

3x95 |

2.5 |

3.0 |

53 |

0.193 |

0.320 |

1350 |

762 |

|

3x 120 |

2.5 |

3.0 |

57 |

0.153 |

0.253 |

1640 |

897 |

|

3x 150 |

2.5 |

3.0 |

61 |

0.124 |

0.206 |

1947 |

1019 |

|

3x 185 |

2.5 |

3.0 |

63 |

0.0991 |

0.164 |

2302 |

1152 |

|

3x240 |

2 6 |

3 5 |

70 |

0 0754 |

0 125 |

2886 |

1400 |

|

3x300 |

2.8 |

3.5 |

75 |

0.0601 |

0.100 |

3351 |

1626 |

Technical Characteristics of 6/6kV,6/10kV for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 3-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x25 |

3.4 |

2.5 |

42 |

0.727 |

1.20 |

1895 |

1430 |

|

3x35 |

3.4 |

2.5 |

44 |

0.524 |

0.868 |

2293 |

1640 |

|

3x50 |

3.4 |

2.5 |

46 |

0.387 |

0.641 |

2812 |

1881 |

|

3x70 |

3.4 |

3.0 |

50 |

0.268 |

0.443 |

3508 |

2205 |

|

3x95 |

3.4 |

3.0 |

54 |

0.193 |

0.320 |

4402 |

2635 |

|

3x 120 |

3.4 |

3.0 |

58 |

0.153 |

0.253 |

5319 |

3087 |

|

3x 150 |

3.4 |

3.0 |

62 |

0.124 |

0.206 |

6309 |

3518 |

|

3x 185 |

3.4 |

3.0 |

65 |

0.0991 |

0.164 |

7319 |

3877 |

|

3x240 |

3.4 |

3.5 |

71 |

0.0754 |

0.125 |

9218 |

4753 |

|

3x300 |

3.4 |

3.5 |

75 |

0.0601 |

0.100 |

11159 |

5577 |

Technical Characteristics of 8.7/10kV,8.7/15kV for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 3-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x25 |

4.5 |

2.8 |

50 |

0.727 |

1.20 |

2537 |

2072 |

|

3x35 |

4.5 |

2.9 |

53 |

0.524 |

0.868 |

2985 |

2334 |

|

3x50 |

4.5 |

2.9 |

55 |

0.387 |

0.641 |

3529 |

2598 |

|

3x70 |

4.5 |

2.9 |

58 |

0.268 |

0.443 |

4197 |

2895 |

|

3x95 |

4.5 |

3.3 |

63 |

0.193 |

0.320 |

5230 |

3462 |

|

3x 120 |

4.5 |

3.6 |

66 |

0.153 |

0.253 |

6120 |

3888 |

|

3x 150 |

4.5 |

3.6 |

70 |

0.124 |

0.206 |

7207 |

4416 |

|

3x 185 |

4.5 |

3.6 |

74 |

0.0991 |

0.164 |

8378 |

4935 |

|

3x240 |

4.5 |

3.6 |

79 |

0.0754 |

0.125 |

10177 |

5712 |

|

3x300 |

4.5 |

3.8 |

84 |

0.0601 |

0.100 |

12159 |

6577 |

Technical Characteristics of 12/20kV for CU or AL conductor/XLPE Insulated /PVC Sheathed Power Cable, 3-core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x35 |

5.5 |

3.0 |

57 |

0.524 |

0.868 |

3348 |

2696 |

|

3x50 |

5.5 |

3.0 |

60 |

0.387 |

0.641 |

3904 |

2973 |

|

3x70 |

5.5 |

3.0 |

63 |

0.268 |

0.443 |

4623 |

3321 |

|

3x95 |

5.5 |

3.5 |

67 |

0.193 |

0.320 |

5593 |

3825 |

|

3x 120 |

5.5 |

3.5 |

71 |

0.153 |

0.253 |

6495 |

4262 |

|

3x 150 |

5.5 |

3.5 |

74 |

0.124 |

0.206 |

7637 |

4846 |

|

3x 185 |

5.5 |

3.5 |

78 |

0.0991 |

0.164 |

8803 |

5361 |

|

3x240 |

5.5 |

3.5 |

84 |

0.0754 |

0.125 |

10729 |

6263 |

|

3x300 |

5.5 |

4.0 |

89 |

0.0601 |

0.100 |

12723 |

7141 |

Construction of 0.6/1kV 3-core, CU or AL conductor/XLPE Insulated/Steel Tape Armored/PVC Sheathed Power Cable

|

No |

Construction and materials |

|

1 |

Copper or aluminum conductor |

|

2 |

XLPE insulation |

|

3 |

PP yarn or glass fiber rope filler |

|

4 |

Non-woven cloth tape or glass fiber tape |

|

5 |

Non-flame retardant or flame retardant PVC bedding |

|

6 |

Steel tape armor |

|

7 |

Non-flame retardant or flame retardant PVC outer sheath |

Technical Characteristics for 12/20kV, CU or AL conductor/XLPE Insulated/ Steel Tape Armored/ PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x 10 |

0.7 |

1.5 |

18 |

1.83 |

3.08 |

622 |

433 |

|

3x 16 |

0.7 |

2.0 |

22 |

1.15 |

1.91 |

1005 |

705 |

|

3x25 |

0.9 |

2.0 |

25 |

0.727 |

1.20 |

1371 |

898 |

|

3x35 |

0.9 |

2.0 |

27 |

0.524 |

0.868 |

1724 |

1061 |

|

3x50 |

1.0 |

2.0 |

30 |

0.387 |

0.641 |

2247 |

1300 |

|

3x70 |

1.1 |

2.5 |

35 |

0.268 |

0.443 |

3023 |

1697 |

|

3x95 |

1.1 |

2.5 |

39 |

0.193 |

0.320 |

3825 |

2026 |

|

3x 120 |

1.2 |

2.5 |

42 |

0.153 |

0.253 |

4642 |

2370 |

|

3x 150 |

1.4 |

3.0 |

48 |

0.124 |

0.206 |

5767 |

2926 |

|

3x 185 |

1.6 |

3.0 |

51 |

0.0991 |

0.164 |

6896 |

3391 |

|

3x240 |

1.7 |

3.0 |

56 |

0.0754 |

0.125 |

8617 |

4072 |

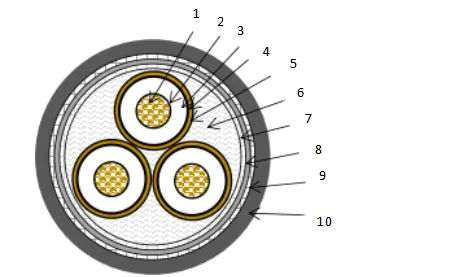

Construction of 3.6/6kV to 26/35kV 3-core, CU or AL conductor/XLPE Insulated /Steel Tape Armored/PVC Sheathed Power Cable

|

No |

Construction and materials |

|

|

1 |

Copper or aluminum conductor |

|

|

2 |

Semi-conductive conductor screen |

|

|

3 |

XLPE insulation |

|

|

4 |

Semi-conductive insulation screen |

|

|

5 |

Copper tape screen |

|

|

6 |

PP yarn or glass fiber rope filler |

|

|

7 |

Non-woven cloth tape or glass fiber tape |

|

|

8 |

Non-flame retardant or flame retardant PVC bedding |

|

|

9 |

Steel tape/wire armor |

|

|

10 |

- |

PVC |

Technical Characteristics for 3.6/6kV, CU or AL conductor/ XLPE Insulated/ Steel Tape Armored/ PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x25 |

2.5 |

2.6 |

46 |

0.727 |

1.20 |

2945 |

2480 |

|

3x35 |

2.5 |

2.6 |

49 |

0.524 |

0.868 |

3390 |

2739 |

|

3x50 |

2.5 |

2.8 |

52 |

0.387 |

0.641 |

4065 |

3135 |

|

3x70 |

2.5 |

2.8 |

55 |

0.268 |

0.443 |

4816 |

3513 |

|

3x95 |

2.5 |

3.1 |

60 |

0.193 |

0.320 |

5897 |

4129 |

|

3x 120 |

2.5 |

3.1 |

63 |

0.153 |

0.253 |

6844 |

4611 |

|

3x 150 |

2.5 |

3.3 |

67 |

0.124 |

0.206 |

7973 |

5182 |

|

3x 185 |

2.5 |

3.5 |

71 |

0.0991 |

0.164 |

9281 |

5838 |

|

3x240 |

2.6 |

3.6 |

77 |

0.0754 |

0.125 |

11229 |

6763 |

|

3x300 |

2.8 |

3.7 |

83 |

0.0601 |

0.100 |

14106 |

8524 |

Technical Characteristics for 6.6/6kV, 6/10kV, CU or AL conductor/XLPE Insulated/Steel Tape Armored/PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x25 |

3.4 |

2.6 |

47 |

0.727 |

1.20 |

3010 |

2544 |

|

3x35 |

3.4 |

2.8 |

50 |

0.524 |

0.868 |

3498 |

2847 |

|

3x50 |

3.4 |

2.8 |

53 |

0.387 |

0.641 |

4135 |

3205 |

|

3x70 |

3.4 |

3.1 |

56 |

0.268 |

0.443 |

4958 |

3655 |

|

3x95 |

3.4 |

3.1 |

61 |

0.193 |

0.320 |

5974 |

4206 |

|

3x 120 |

3.4 |

3.2 |

64 |

0.153 |

0.253 |

6969 |

4736 |

|

3x 150 |

3.4 |

3.6 |

69 |

0.124 |

0.206 |

8161 |

5370 |

|

3x 185 |

3.4 |

3.6 |

72 |

0.0991 |

0.164 |

9417 |

5975 |

|

3x240 |

3.4 |

3.6 |

78 |

0.0754 |

0.125 |

11340 |

6874 |

|

3x300 |

3.4 |

3.8 |

84 |

0.0601 |

0.100 |

14247 |

8665 |

Technical Characteristics for 8.7/10kV,8.7/15kV,CU or AL conductor/XLPE Insulated/ Steel Tape Armored/ PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x25 |

4.5 |

2.9 |

53 |

0.727 |

1.20 |

3500 |

3035 |

|

3x35 |

4.5 |

2.9 |

55 |

0.524 |

0.868 |

3329 |

3329 |

|

3x50 |

4.5 |

3.1 |

58 |

0.387 |

0.641 |

4679 |

3748 |

|

3x70 |

4.5 |

3.1 |

61 |

0.268 |

0.443 |

5410 |

4107 |

|

3x95 |

4.5 |

3.4 |

66 |

0.193 |

0.320 |

6567 |

4799 |

|

3x 120 |

4.5 |

3.4 |

70 |

0.153 |

0.253 |

7541 |

5308 |

|

3x 150 |

4.5 |

3.6 |

73 |

0.124 |

0.206 |

8674 |

5883 |

|

3x 185 |

4.5 |

3.6 |

77 |

0.0991 |

0.164 |

9991 |

6549 |

|

3x240 |

4 5 |

4 0 |

84 |

0 0754 |

0 125 |

12887 |

8421 |

|

3x300 |

4.5 |

4.0 |

89 |

0.0601 |

0.100 |

14974 |

9392 |

Technical Characteristics for 12/20kV, CU or AL conductor/XLPE Insulated/ Steel Tape Armored/PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x35 |

5.5 |

3.2 |

63 |

0.524 |

0.868 |

4840 |

4189 |

|

3x50 |

5.5 |

3.2 |

66 |

0.387 |

0.641 |

5463 |

4532 |

|

3x70 |

5.5 |

3.3 |

69 |

0.268 |

0.443 |

6346 |

5044 |

|

3x95 |

5.5 |

3.6 |

74 |

0.193 |

0.320 |

7457 |

5689 |

|

3x 120 |

5.5 |

3.6 |

77 |

0.153 |

0.253 |

8459 |

6227 |

|

3x 150 |

5.5 |

3.8 |

82 |

0.124 |

0.206 |

10555 |

7764 |

|

3x 185 |

5.5 |

4.0 |

86 |

0.0991 |

0.164 |

11925 |

8483 |

|

3x240 |

5.5 |

4.0 |

92 |

0.0754 |

0.125 |

13959 |

9494 |

|

3x300 |

5.5 |

4.2 |

97 |

0.0601 |

0.100 |

16314 |

10731 |

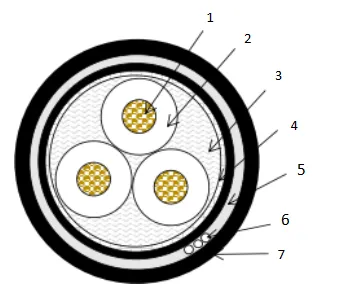

Construction of 0.6/1kV 3-core, CU or AL conductor/XLPE Insulated/Steel Wire Armored/PVC Sheathed Power Cable

|

No |

Construction and materials |

|

1 |

Copper or aluminum conductor |

|

2 |

XLPE insulation |

|

3 |

PP yarn or glass fiber rope filler |

|

4 |

Non-woven cloth tape or glass fiber tape |

|

5 |

Non-flame retardant or flame retardant PVC bedding |

|

6 |

Steel wire armor |

|

7 |

Non-flame retardant or flame retardant PVC sheath |

Technical Characteristics for 0.6/1kV, CU or AL conductor/ XLPE Insulated/ Steel Wire Armored/PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x 10 |

0.7 |

2.0 |

21 |

1.83 |

3.08 |

820 |

630 |

|

3x 16 |

0.7 |

2.0 |

25 |

1.15 |

1.91 |

1450 |

1150 |

|

3x25 |

0.9 |

2.0 |

28 |

0.727 |

1.20 |

1850 |

1400 |

|

3x35 |

0.9 |

2.0 |

31 |

0.524 |

0.868 |

2300 |

1650 |

|

3x50 |

1.0 |

2.0 |

32 |

0.387 |

0.641 |

2650 |

1750 |

|

3x70 |

1.1 |

2.5 |

38 |

0.268 |

0.443 |

3650 |

2350 |

|

3x95 |

1.1 |

2.5 |

41 |

0.193 |

0.320 |

4550 |

2800 |

|

3x 120 |

1.2 |

3.0 |

43 |

0.153 |

0.253 |

5450 |

3200 |

|

3x 150 |

1.4 |

3.0 |

48 |

0.124 |

0.206 |

7000 |

4200 |

|

3x 185 |

1.6 |

3.0 |

58 |

0.0991 |

0.164 |

9328 |

5849 |

|

3x240 |

1.7 |

3.5 |

65 |

0.0754 |

0.125 |

11236 |

6587 |

Construction of 3.6/6kV to 26/35kV 3-core, CU or AL conductor/XLPE Insulated/Steel Wire Armored/PVC Sheathed Power Cable

|

No |

Construction and materials |

|

|

1 |

Copper or aluminum conductor |

|

|

2 |

Semi-conductive conductor screen |

|

|

3 |

XLPE insulation |

|

|

4 |

Semi-conductive insulation screen |

|

|

5 |

Copper tape screen |

|

|

6 |

PP yarn or glass fiber rope filler |

|

|

7 |

Non-woven cloth tape or glass fiber tape |

|

|

8 |

Non-flame retardant or flame retardant PVC bedding |

|

|

9 |

Steel wire armor |

|

|

10 |

- |

PVC |

Technical Characteristics for 3.6/6kV,CU or AL conductor/XLPE Insulated/Steel Wire Armored/PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x25 |

2.5 |

2.5 |

49 |

0.727 |

1.20 |

4246 |

3781 |

|

3x35 |

2.5 |

3.0 |

52 |

0.524 |

0.868 |

4770 |

4119 |

|

3x50 |

2.5 |

3.0 |

57 |

0.387 |

0.641 |

6194 |

5263 |

|

3x70 |

2.5 |

3.0 |

60 |

0.268 |

0.443 |

7092 |

5790 |

|

3x95 |

2.5 |

3.0 |

64 |

0.193 |

0.320 |

8263 |

6495 |

|

3x 120 |

2.5 |

3.5 |

68 |

0.153 |

0.253 |

9422 |

7190 |

|

3x 150 |

2.5 |

3.5 |

71 |

0.124 |

0.206 |

10667 |

7876 |

|

3x 185 |

2.5 |

3.5 |

76 |

0.0991 |

0.164 |

12113 |

8671 |

|

3x240 |

2.6 |

3.5 |

81 |

0.0754 |

0.125 |

14361 |

9895 |

|

3x300 |

2.8 |

3.5 |

87 |

0.0601 |

0.100 |

16632 |

11050 |

Technical Characteristics for 6.6/6kV,6/10kV, CU or AL conductor/XLPE Insulated/ Steel Wire Armored/PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness

(mm) |

Nominal sheath thickness

(mm) |

Approx Overall Diameter

(mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x25 |

3.4 |

3.0 |

50 |

0.727 |

1.20 |

4337 |

3872 |

|

3x35 |

3.4 |

3.0 |

53 |

0.524 |

0.868 |

4863 |

4212 |

|

3x50 |

3.4 |

3.0 |

58 |

0.387 |

0.641 |

6302 |

5371 |

|

3x70 |

3.4 |

3.0 |

61 |

0.268 |

0.443 |

7177 |

5875 |

|

3x95 |

3.4 |

3.5 |

65 |

0.193 |

0.320 |

8431 |

6663 |

|

3x 120 |

3.4 |

3.5 |

69 |

0.153 |

0.253 |

9559 |

7326 |

|

3x 150 |

3.4 |

3.5 |

73 |

0.124 |

0.206 |

10873 |

8246 |

|

3x 185 |

3.4 |

3.5 |

76 |

0.0991 |

0.164 |

12256 |

8814 |

|

3x240 |

3 4 |

3 5 |

82 |

0 0754 |

0 125 |

14509 |

10044 |

|

3x300 |

3.4 |

4.0 |

88 |

0.0601 |

0.100 |

16821 |

11239 |

Technical Characteristics for 8.7/10kV,8.7/15kV,CU or AL conductor/XLPE Insulated/ Steel Wire Armored/ PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness

(mm) |

Nominal sheath thickness

(mm) |

Approx Overall Diameter

(mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x25 |

4.5 |

3.2 |

60 |

0.727 |

1.20 |

6058 |

5593 |

|

3x35 |

4.5 |

3.2 |

63 |

0.524 |

0.868 |

6661 |

6010 |

|

3x50 |

4.5 |

3.2 |

66 |

0.387 |

0.641 |

7456 |

6525 |

|

3x70 |

4.5 |

3.4 |

69 |

0.268 |

0.443 |

8376 |

7074 |

|

3x95 |

4.5 |

3.4 |

73 |

0.193 |

0.320 |

9657 |

7890 |

|

3x 120 |

4.5 |

3.5 |

76 |

0.153 |

0.253 |

10834 |

8602 |

|

3x 150 |

4.5 |

3.8 |

81 |

0.124 |

0.206 |

12160 |

9369 |

|

3x 185 |

4.5 |

3.8 |

85 |

0.0991 |

0.164 |

13661 |

10219 |

|

3x240 |

4.5 |

4.2 |

91 |

0.0754 |

0.125 |

15992 |

11527 |

|

3x300 |

4.5 |

4.2 |

96 |

0.0601 |

0.100 |

18262 |

12680 |

Technical Characteristics for 12/20kV, CU or AL conductor/XLPE Insulated/ Steel Wire Armored/ PVC Sheathed Power Cable, 3-Core

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3x35 |

5.5 |

3.5 |

68 |

0.524 |

0.868 |

7430 |

6752 |

|

3x50 |

5.5 |

3.5 |

70 |

0.387 |

0.641 |

8139 |

7208 |

|

3x70 |

5.5 |

3.5 |

74 |

0.268 |

0.443 |

9133 |

7831 |

|

3x95 |

5.5 |

3.5 |

78 |

0.193 |

0.320 |

10450 |

8682 |

|

3x 120 |

5.5 |

3.5 |

82 |

0.153 |

0.253 |

11612 |

9379 |

|

3x 150 |

5.5 |

4.0 |

86 |

0.124 |

0.206 |

12982 |

10191 |

|

3x 185 |

5.5 |

4.0 |

89 |

0.0991 |

0.164 |

14540 |

11098 |

|

3x240 |

5.5 |

4.0 |

95 |

0.0754 |

0.125 |

16751 |

12285 |

|

3x300 |

5.5 |

4.0 |

101 |

0.0601 |

0.100 |

19242 |

13660 |