Construction Conductor

Plain circular or sector stranded copper conductors, per IEC:228 class 1 and 2.

Insulation

XLPE (cross-linked polyethylene) rated 90°C.

Assembly

Two, three or four insulated cores are assembled together.

Inner sheath

In single core cables, inner sheath of halogen free compound is applied over insulation. In multicore cables, assembled cores are covered with inner sheath of halogen free compound.

Armour

For single core cables, a layer of aluminium wires applied helically over inner sheath. For multicore cables, galvanised round steel wires applied helically over inner sheath.

Sheath

LSF-FR-HF compound, colour black.

Colours for core identification

Single core - red (black colour on request) Two cores - red and black

Three cores - red, yellow and blue

Four cores - red, yellow, blue and black

Features: Cables manufactured with the above construction have a combination of high flame retardancy as well as low smoke and non-halogen acid gas generation. This makes these cables ideal to install in locations such as chemical plants, hospitals, military installations, underground railways, tunnels, etc

Application: These cables are intended for installation on cable trays or in cable ducts.

Awa armoured LSF-FR-HF Cables- Single Core Copper Conductor - XLPE Insulated 0.6/1kV

|

Conductor |

Insulation |

Armouring |

Outer sheath |

Packaging |

|||

|

Cross sectional area Nominal |

Minimum number of wires |

Thickness Nominal |

Diameter of aluminium wire Nominal |

Thickness Nominal |

Overall diameter Approx |

Net weight Appro x |

Standard package |

|

mm² |

mm |

mm |

mm |

mm |

kg/km |

m±5% |

|

|

50 |

6 |

1.0 |

1.25 |

1.5 |

18.2 |

710 |

1000 |

|

70 |

12 |

1.1 |

1.25 |

1.5 |

20.2 |

940 |

1000 |

|

95 |

15 |

1.1 |

1.25 |

1.6 |

22.3 |

1220 |

1000 |

|

120 |

18 |

1.2 |

1.25 |

1.6 |

24.2 |

1480 |

1000 |

|

150 |

18 |

1.4 |

1.60 |

1.7 |

27.4 |

1870 |

500 |

|

185 |

30 |

1.6 |

1.60 |

1.8 |

30.0 |

2280 |

500 |

|

240 |

34 |

1.7 |

1.60 |

1.8 |

32.8 |

2880 |

500 |

|

300 |

34 |

1.8 |

1.60 |

1.9 |

35.6 |

3520 |

500 |

|

400 |

53 |

2.0 |

2.00 |

2.0 |

40.4 |

4520 |

500 |

|

500 |

53 |

2.2 |

2.00 |

2.1 |

44.2 |

5640 |

500 |

|

630 |

53 |

2.4 |

2.00 |

2.2 |

48.8 |

7110 |

500 |

RSW Armoured LSF-FR-HF Cables - Multi Core Copper Conductors- XLPE Insulated 0.6/1kV

|

Conductor |

Insulation |

Armouring |

Outer sheath |

Packaging |

|||

|

Cross sectional area Nominal |

Minimum number of wires |

Thickness Nominal |

Diameter of aluminium wire Nominal |

Thickness Nominal |

Overall diameter Approx |

Net weight Approx |

Standard package |

|

mm² |

mm |

mm |

mm |

mm |

kg/km |

m±5% |

|

|

2.5 rm |

7 |

0.7 |

1.25 |

1.4 |

14.3 |

500 |

1000 |

|

4 rm |

7 |

0.7 |

1.25 |

1.4 |

15.4 |

560 |

1000 |

|

6 rm |

7 |

0.7 |

1.25 |

1.4 |

16.6 |

670 |

1000 |

|

10 rm |

7 |

0.7 |

1.25 |

1.5 |

18.7 |

850 |

1000 |

|

16 rm |

6 |

0.7 |

1.25 |

1.5 |

20.0 |

1060 |

1000 |

|

25 rm |

6 |

0.9 |

1.25 |

1.6 |

24.1 |

1620 |

1000 |

|

35 rm |

6 |

0.9 |

1.60 |

1.7 |

23.4 |

1930 |

500 |

|

2.5 rm |

7 |

0.7 |

1.25 |

1.4 |

14.8 |

540 |

1000 |

|

4 rm |

7 |

0.7 |

1.25 |

1.4 |

16.0 |

620 |

1000 |

|

6 rm |

7 |

0.7 |

1.25 |

1.4 |

17.3 |

755 |

1000 |

|

10 rm |

7 |

0.7 |

1.25 |

1.5 |

20.2 |

960 |

1000 |

|

16 rm |

6 |

0.7 |

1.25 |

1.6 |

21.2 |

1240 |

1000 |

|

25 rm |

6 |

0.9 |

1.60 |

1.7 |

26.7 |

1720 |

500 |

|

35 sm |

6 |

0.9 |

1.60 |

1.8 |

25.9 |

2130 |

500 |

|

50 sm |

6 |

1.0 |

1.60 |

1.8 |

28.5 |

2380 |

500 |

|

70 sm |

12 |

1.1 |

1.60 |

1.9 |

32.2 |

3150 |

500 |

|

95 sm |

15 |

1.1 |

2.00 |

2.1 |

37.0 |

4320 |

500 |

|

120 sm |

18 |

1.2 |

2.00 |

2.2 |

40.4 |

5200 |

500 |

|

150 sm |

18 |

1.4 |

2.50 |

2.3 |

45.5 |

6620 |

500 |

|

185 sm |

30 |

1.6 |

2.50 |

2.4 |

49.8 |

7980 |

500 |

|

240 sm |

34 |

1.7 |

2.50 |

2.6 |

55.1 |

9960 |

250 |

|

300 sm |

34 |

1.8 |

2.50 |

2.7 |

60.2 |

12060 |

250 |

rm - circular stranded conductor sm - sectoral stranded conductor

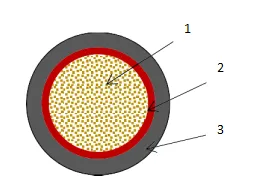

Single Core Cable

1. Conductor

2. PVC Insulation Type 5

3. PVC

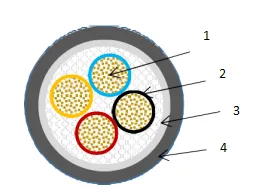

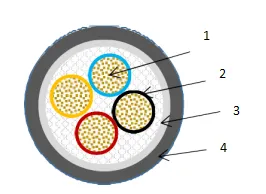

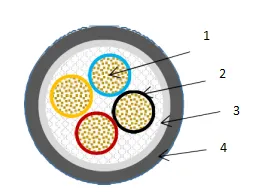

Multi-core Cable

1. Conductor

2. PVC Insulation

3. Extruded bedding

4. PVC Sheath

Multi-core Cable

1. Sectoral Aluminum/Copper Conductor

2. PVC Insulation Type 5

3. Central Filler

4. Extruded bedding

5. Round Steel Wire Armoured

6. LSF-FR-HF compound sheath