Installation Temperature: The installation temperature should be over 0C,If the ambient temperature is lower than 0C,the cable should be preheated.

Operating temperature: Max permissible continuous operating temperature of conductor shall not exceed 70C.

Conductor Short-circuit Temperature: Max temperature at short-circuit shall conductor shall not exceed 160C,The short-circuit duration shall not exceed 5 seconds.

Bending Radius: 20( d+D) +/-5% for single core cable,15( d+D )+/-5% for multi-core cable.

D=Actual outer diameter of cable (mm),d=Actual diameter of the conductor (mm)

Standard: IEC 12706,IEC60502 or other standard required by customer.

The requirements for flame retardant property is according to IEC60332-3 and GB18380.

Packing: Steel/wooden reel,wooden reel or steel reel.

|

Description |

Application |

|

Cu or Al conductor/PVC insulated/PVC sheathed/ power cable |

It is installed in indoor,in duct or in tunnel,but unable to bear pulling force and pressure |

|

Cu or Al conductor/PVC insulated/steel tape armored/PVC sheathed/ power cable |

It is installed in indoor,i in tunnel,directly in ground,able to bear proper pressure |

|

Cu or Al conductor/PVC insulated/steel wire armored/PVC sheathed/ power cable |

It is installed in indoor,in well,under water, able to bear proper pulling force |

|

Cu or Al conductor/PVC insulated/PVC sheathed/ flame retardant power cable |

It is installed in indoor,in duct or in tunnel,but unable to bear pulling force and pressure |

|

Cu or Al conductor/PVC insulated/steel tape armored/PVC sheathed/ flame retardant power cable |

It is installed in indoor,i in tunnel,directly in ground,able to bear proper pressure |

|

Cu or Al conductor/PVC insulated/steel wire armored/PVC sheathed/flame retardant power cable |

It is installed in indoor,in well,under water, able to bear proper pulling force |

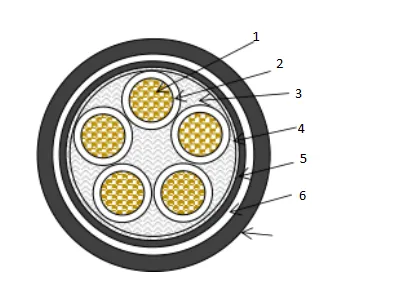

Construction of 0.6/1kV PVC Insulated Power Cable

|

No |

Construction and material |

|

1 |

Copper or aluminum conductor |

|

2 |

PVC insulation |

|

3 |

PP yarn or glass fiber rope filler |

|

4 |

Non-woven cloth tape or glass fiber tape |

|

5 |

Non flame retardant or flame retardant PVC bedding |

|

6 |

Steel tape or steel wire armor |

|

7 |

Non flame retardant or flame retardant PVC outer sheath |

|

Description |

No of cores |

Nominal conductor cross section area (mm2) |

|

|

Cu or Al conductor/PVC or flame retardant PVC insulated/PVC or flame retardant PVC sheathed |

1 |

1.5 to 630 |

1.5 to 630 |

|

2 |

1.5 to 400 |

1.5 to 400 |

|

|

3 |

1.5 to 400 |

1.5 to 400 |

|

|

4 |

2.5 to 400 |

2.5 to 400 |

|

|

5 |

2.5 to 400 |

2.5 to 400 |

|

|

Cu or Al conductor/PVC or flame retardant PVC insulated/steel tape or wire armor/PVC or flame retardant PVC sheathed |

2,3,4,5 |

4 to 400 |

4 to 400 |

Technical Characteristics for CU or AL/PVC/PVC,SINGLE CORE

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter

(mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

1x 1.5 |

0.8 |

1.54 |

6.1 |

12.1 |

--- |

50.7 |

41.3 |

|

1x2.5 |

0.8 |

1.54 |

6.5 |

7.41 |

12.1 |

63.5 |

47.9 |

|

1x4 |

1.0 |

1.54 |

7.4 |

4.61 |

7.41 |

87.7 |

63.0 |

|

1x6 |

1.0 |

1.54 |

7.9 |

3.08 |

4.61 |

111.0 |

75.9 |

|

1x10 |

1.0 |

1.54 |

9.2 |

1.83 |

3.02 |

166.6 |

93.0 |

|

1x16 |

1.0 |

1.54 |

10.3 |

1.15 |

1.91 |

233.3 |

132.2 |

|

1x25 |

1.2 |

1.54 |

12.0 |

0.727 |

1.20 |

344.9 |

185.4 |

|

1x35 |

1.2 |

1.54 |

13.2 |

0.524 |

0.868 |

449.8 |

228.7 |

|

1x50 |

1.4 |

1.54 |

14.9 |

0.387 |

0.641 |

590.5 |

289.8 |

|

1x70 |

1.4 |

1.54 |

16.7 |

0.268 |

0.443 |

807.3 |

374.2 |

|

1x95 |

1.6 |

1.65 |

19.3 |

0.193 |

0.320 |

1102.0 |

501.4 |

|

1x 120 |

1.6 |

1.65 |

20.9 |

0.153 |

0.253 |

1349.0 |

590.3 |

|

1x 150 |

1.8 |

1.76 |

23.1 |

0.124 |

0.206 |

1654.0 |

721.3 |

|

1x 185 |

2.0 |

1.87 |

25.6 |

0.0991 |

0.164 |

2060.0 |

891.6 |

|

1x240 |

2.2 |

1.98 |

28.8 |

0.0754 |

0.125 |

2651.0 |

1114.0 |

|

1x300 |

2.4 |

2.09 |

31.9 |

0.0601 |

0.100 |

3323.0 |

1396.0 |

|

1x400 |

2.6 |

2.20 |

35.5 |

0.0470 |

0.0778 |

4205.0 |

1742.0 |

|

1x500 |

2.8 |

2.31 |

39.7 |

0.0366 |

0.0605 |

5359.0 |

2128.0 |

|

1x630 |

2.8 |

2.40 |

43.7 |

0.0283 |

0.0469 |

6707.0 |

2605.0 |

Technical Characteristics for CU or AL/PVC/PVC,2 CORES

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

2X1.5 |

0.8 |

1.8 |

10.5 |

12.1 |

--- |

119.0 |

100.0 |

|

2X2.5 |

0.8 |

1.8 |

11.3 |

7.41 |

12.1 |

150.0 |

118.0 |

|

2X4 |

1.0 |

1.8 |

13.1 |

4.61 |

7.41 |

210.0 |

160.0 |

|

2X6 |

1.0 |

1.8 |

14.1 |

3.08 |

4.61 |

264.0 |

192.0 |

|

2X10 |

1.0 |

1.8 |

16.7 |

1.83 |

3.02 |

393.0 |

242.0 |

|

2X16 |

1.0 |

1.8 |

18.8 |

1.15 |

1.91 |

541.0 |

334.0 |

|

2X25 |

1.2 |

1.8 |

19.6 |

0.727 |

1.20 |

794.0 |

469.0 |

|

2X35 |

1.2 |

1.8 |

21.8 |

0.524 |

0.868 |

1037.0 |

585.0 |

|

2X50 |

1.4 |

1.8 |

25.1 |

0.387 |

0.641 |

1227.0 |

620.0 |

|

2X70 |

1.4 |

1.9 |

28.2 |

0.268 |

0.443 |

1650.0 |

747.0 |

|

2X95 |

1.6 |

2.0 |

29.2 |

0.193 |

0.320 |

2213.0 |

988.0 |

|

2X120 |

1.6 |

2.1 |

31.3 |

0.153 |

0.253 |

2733.0 |

1186.0 |

|

2X150 |

1.8 |

2.2 |

34.7 |

0.124 |

0.206 |

3396.0 |

1462.0 |

|

2X185 |

2.0 |

2.4 |

37.9 |

0.0991 |

0.164 |

3943.0 |

1559.0 |

Technical Characteristics for CU or AL/PVC/PVC,3-CORES

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

||||

|

3X1.5 |

0.8 |

1.8 |

10.9 |

12.1 |

--- |

142 |

113 |

|

3X2.5 |

0.8 |

1.8 |

11.8 |

7.41 |

12.1 |

187 |

139 |

|

3X4 |

1.0 |

1.8 |

13.7 |

4.61 |

7.41 |

265 |

189 |

|

3X6 |

1.0 |

1.8 |

14.8 |

3.08 |

4.61 |

335 |

227 |

|

3X10 |

1.0 |

1.8 |

17.6 |

1.83 |

3.02 |

514 |

290 |

|

3X16 |

1.0 |

1.8 |

19.9 |

1.15 |

1.91 |

728 |

419 |

|

3X25 |

1.2 |

1.8 |

23.6 |

0.727 |

1.20 |

1084 |

596 |

|

3X35 |

1.2 |

1.8 |

26.1 |

0.524 |

0.868 |

1422 |

745 |

|

3X50 |

1.4 |

1.8 |

26.5 |

0.387 |

0.641 |

1801 |

834 |

|

3X70 |

1.4 |

1.9 |

28.8 |

0.268 |

0.443 |

2415 |

1061 |

|

3X95 |

1.6 |

2.1 |

33.6 |

0.193 |

0.320 |

3205 |

1418 |

|

3X120 |

1.6 |

2.2 |

37.1 |

0.153 |

0.253 |

4037 |

1716 |

|

3X150 |

1.8 |

2.3 |

41.9 |

0.124 |

0.206 |

5028 |

2127 |

|

3X185 |

2.0 |

2.5 |

45.9 |

0.0991 |

0.164 |

6180 |

2602 |

|

3X240 |

2.2 |

2.7 |

51.8 |

0.0754 |

0.125 |

7949 |

3308 |

|

3X300 |

2.4 |

2.8 |

55.3 |

0.0601 |

0.100 |

9780 |

3979 |

Technical Characteristics for CU or AL/PVC/PVC,4-CORES

|

Nominal conductor cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

|

Al |

||||

|

4X2.5 |

0.8 |

1.8 |

12.7 |

7.41 |

12.1 |

232 |

169 |

|

4X4 |

1.0 |

1.8 |

14.9 |

4.61 |

7.41 |

322 |

221 |

|

4X6 |

1.0 |

1.8 |

16.1 |

3.08 |

4.61 |

422 |

271 |

|

4X10 |

1.0 |

1.8 |

19.2 |

1.83 |

3.02 |

649 |

388 |

|

4X16 |

1.0 |

1.8 |

21.7 |

1.15 |

1.91 |

922 |

509 |

|

4X25 |

1.2 |

1.8 |

25.9 |

0.727 |

1.20 |

1373 |

722 |

|

4X35 |

1.2 |

1.8 |

28.7 |

0.524 |

0.868 |

1802 |

899 |

|

4X50 |

1.4 |

1.9 |

30.4 |

0.387 |

0.641 |

2380 |

1091 |

|

4X70 |

1.4 |

2.0 |

33.9 |

0.268 |

0.443 |

3202 |

1398 |

|

4X95 |

1.6 |

2.2 |

39.7 |

0.193 |

0.320 |

4315 |

1866 |

|

4X120 |

1.6 |

2.3 |

44.2 |

0.153 |

0.253 |

5359 |

2265 |

|

4X150 |

1.8 |

2.5 |

48.7 |

0.124 |

0.206 |

6679 |

2811 |

|

4X185 |

2.0 |

2.6 |

53.5 |

0.0991 |

0.164 |

8190 |

3420 |

|

4X240 |

2.2 |

2.9 |

55.4 |

0.0754 |

0.125 |

10494 |

4305 |

|

4X300 |

2.4 |

3.1 |

60.2 |

0.0601 |

0.100 |

12948 |

5215 |

Technical Characteristics for CU or AL/PVC Insulated/Steel Tape Armored/PVC sheathed Power Cable, 2-CORES

|

Nominal conduct or cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal Bedding Thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

|||||

|

2X4 |

1.0 |

1.2 |

1.8 |

13.1 |

4.61 |

7.41 |

210 |

160 |

|

2X6 |

1.0 |

1.2 |

1.8 |

14.1 |

3.08 |

4.61 |

264 |

192 |

|

2X10 |

1.0 |

1.2 |

1.8 |

16.7 |

1.83 |

3.02 |

393 |

242 |

|

2X16 |

1.0 |

1.2 |

1.8 |

18.8 |

1.15 |

1.91 |

541 |

334 |

|

2X25 |

1.2 |

1.2 |

1.8 |

22.2 |

0.727 |

1.20 |

794 |

469 |

|

2X35 |

1.2 |

1.2 |

1.8 |

24.5 |

0.524 |

0.868 |

1037 |

585 |

|

2X50 |

1.4 |

1.2 |

1.8 |

21.8 |

0.387 |

0.641 |

1227 |

610 |

|

2X70 |

1.4 |

1.2 |

1.9 |

24.7 |

0.268 |

0.443 |

1650 |

747 |

|

2X95 |

1.6 |

1.2 |

2.0 |

29.2 |

0.193 |

0.320 |

2213 |

988 |

|

2X120 |

1.6 |

1.2 |

2.1 |

31.3 |

0.153 |

0.253 |

2733 |

1186 |

|

2X150 |

1.8 |

1.3 |

2.2 |

34.7 |

0.124 |

0.206 |

3396 |

1462 |

|

2X185 |

2.0 |

1.4 |

2.2 |

39.2 |

0.0991 |

0.164 |

4112 |

1726 |

Technical Characteristics for CU or AL/PVC Insulated/Steel Tape Armored /PVC sheathed Power Cable, 3-CORES

|

Nominal conduct or cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal Bedding Thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

|||||

|

3X4 |

1.0 |

1.2 |

1.8 |

17.3 |

4.61 |

7.41 |

489 |

414 |

|

3X6 |

1.0 |

1.2 |

1.8 |

18.4 |

3.08 |

4.61 |

577 |

472 |

|

3X10 |

1.0 |

1.2 |

1.8 |

21.2 |

1.83 |

3.02 |

800 |

559 |

|

3X16 |

1.0 |

1.2 |

1.8 |

23.5 |

1.15 |

1.91 |

1050 |

740 |

|

3X25 |

1.2 |

1.2 |

1.8 |

27.2 |

0.727 |

1.20 |

1465 |

976 |

|

3X35 |

1.2 |

1.2 |

1.9 |

30.7 |

0.524 |

0.868 |

2149 |

1372 |

|

3X50 |

1.4 |

1.2 |

2.0 |

31.3 |

0.387 |

0.641 |

2453 |

1486 |

|

3X70 |

1.4 |

1.2 |

2.1 |

33.6 |

0.268 |

0.443 |

3116 |

1763 |

|

3X95 |

1.6 |

1.2 |

2.2 |

38.3 |

0.193 |

0.320 |

4053 |

2216 |

|

3X120 |

1.6 |

1.3 |

2.3 |

41.9 |

0.153 |

0.253 |

4930 |

2609 |

|

3X150 |

1.8 |

1.4 |

2.5 |

47.1 |

0.124 |

0.206 |

6075 |

3174 |

|

3X185 |

2.0 |

1.4 |

2.6 |

50.9 |

0.0991 |

0.164 |

7299 |

3721 |

|

3X240 |

2.2 |

1.5 |

2.8 |

57.0 |

0.0754 |

0.125 |

9213 |

4590 |

|

3X300 |

2.4 |

1.7 |

3.0 |

61.1 |

0.0601 |

0.100 |

11185 |

5438 |

Technical Characteristics for CU or AL/PVC Insulated/Steel Tape Armored/PVC sheathed Power Cable, 4-CORES

|

Nominal conduct or cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal Bedding Thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

|||||

|

4X4 |

1.0 |

1.2 |

1.8 |

18.5 |

4.61 |

7.41 |

565 |

464 |

|

4X6 |

1.0 |

1.2 |

1.8 |

19.7 |

3.08 |

4.61 |

685 |

533 |

|

4X10 |

1.0 |

1.2 |

1.8 |

22.8 |

1.83 |

3.02 |

960 |

699 |

|

4X16 |

1.0 |

1.2 |

1.8 |

25.3 |

1.15 |

1.91 |

1273 |

851 |

|

4X25 |

1.2 |

1.2 |

1.9 |

30.5 |

0.727 |

1.20 |

1998 |

1347 |

|

4X35 |

1.2 |

1.2 |

2.0 |

33.5 |

0.524 |

0.868 |

2505 |

1602 |

|

4X50 |

1.4 |

1.2 |

2.1 |

35.2 |

0.387 |

0.641 |

3122 |

1832 |

|

4X70 |

1.4 |

1.2 |

2.2 |

38.7 |

0.268 |

0.443 |

4025 |

2220 |

|

4X95 |

1.6 |

1.3 |

2.3 |

44.7 |

0.193 |

0.320 |

5291 |

2842 |

|

4X120 |

1.6 |

1.4 |

2.5 |

49.4 |

0.153 |

0.253 |

6464 |

3370 |

|

4X150 |

1.8 |

1.4 |

2.6 |

53.7 |

0.124 |

0.206 |

7866 |

3998 |

|

4X185 |

2.0 |

1.5 |

2.8 |

58.9 |

0.0991 |

0.164 |

9542 |

4772 |

|

4X240 |

2.2 |

1.7 |

3.0 |

61.0 |

0.0754 |

0.125 |

11916 |

5727 |

|

4X300 |

2.4 |

1.8 |

3.3 |

66.2 |

0.0601 |

0.100 |

14501 |

6767 |

Technical Characteristics for CU or AL/PVC Insulated/Steel Wire Armored/PVC Sheathed Power Cable, 2-CORES

|

Nominal conduct or cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal Bedding Thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

|||||

|

2X4 |

1.0 |

1.2 |

1.8 |

18.7 |

4.61 |

7.41 |

723 |

672 |

|

2X6 |

1.0 |

1.2 |

1.8 |

19.9 |

3.08 |

4.61 |

818 |

744 |

|

2X10 |

1.0 |

1.2 |

1.8 |

22.3 |

1.83 |

3.02 |

1044 |

802 |

|

2X16 |

1.0 |

1.2 |

1.8 |

25.2 |

1.15 |

1.91 |

1432 |

1225 |

|

2X25 |

1.2 |

1.2 |

1.9 |

28.8 |

0.727 |

1.20 |

1848 |

1522 |

|

2X35 |

1.2 |

1.2 |

1.9 |

31.1 |

0.524 |

0.868 |

2200 |

2003 |

|

2X50 |

1.4 |

1.2 |

2.0 |

28.6 |

0.387 |

0.641 |

2265 |

1620 |

|

2X70 |

1.4 |

1.2 |

2.1 |

31.5 |

0.268 |

0.443 |

2810 |

1907 |

|

2X95 |

1.6 |

1.2 |

2.3 |

36.2 |

0.193 |

0.320 |

3582 |

2357 |

|

2X120 |

1.6 |

1.2 |

2.4 |

38.3 |

0.153 |

0.253 |

4190 |

2643 |

|

2X150 |

1.8 |

1.3 |

2.5 |

42.9 |

0.124 |

0.206 |

5392 |

3459 |

|

2X185 |

2.0 |

1.4 |

2.7 |

48.0 |

0.0991 |

0.164 |

6590 |

5340 |

Technical Characteristics for CU or AL/PVC Insulated/Steel Wire Armored/PVC Sheathed Power Cable, 3-CORES

|

Nominal conduct or cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal Bedding Thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

|||||

|

3X4 |

1.0 |

1.2 |

1.8 |

19.3 |

4.61 |

7.41 |

798 |

722 |

|

3X6 |

1.0 |

1.2 |

1.8 |

20.6 |

3.08 |

4.61 |

908 |

799 |

|

3X10 |

1.0 |

1.2 |

1.8 |

22.1 |

1.83 |

3.02 |

1183 |

965 |

|

3X16 |

1.0 |

1.2 |

1.9 |

26.3 |

1.15 |

1.91 |

1658 |

1349 |

|

3X25 |

1.2 |

1.2 |

1.9 |

30.2 |

0.727 |

1.20 |

2190 |

1701 |

|

3X35 |

1.2 |

1.2 |

2.0 |

32.7 |

0.524 |

0.868 |

2635 |

1957 |

|

3X50 |

1.4 |

1.2 |

2.1 |

33.3 |

0.387 |

0.641 |

3050 |

2083 |

|

3X70 |

1.4 |

1.2 |

2.2 |

35.6 |

0.268 |

0.443 |

3755 |

2401 |

|

3X95 |

1.6 |

1.2 |

2.3 |

41.5 |

0.193 |

0.320 |

5162 |

3324 |

|

3X120 |

1.6 |

1.3 |

2.4 |

45.1 |

0.153 |

0.253 |

6143 |

3822 |

|

3X150 |

1.8 |

1.4 |

2.6 |

51.6 |

0.124 |

0.206 |

8025 |

5124 |

|

3X185 |

2.0 |

1.4 |

2.8 |

55.6 |

0.0991 |

0.164 |

9428 |

5850 |

|

3X240 |

2.2 |

1.5 |

3.0 |

61.7 |

0.0754 |

0.125 |

11612 |

6971 |

|

3X300 |

2.4 |

1.7 |

3.2 |

65.8 |

0.0601 |

0.100 |

13781 |

7980 |

Technical Characteristics for CU or AL/PVC Insulated/Steel Wire Armored/PVC Sheathed Power Cable,4-CORES

|

Nominal conduct or cross section area (mm) |

Nominal Insulation thickness (mm) |

Nominal Bedding Thickness (mm) |

Nominal sheath thickness (mm) |

Approx Overall Diameter (mm) |

Max DC Conductor resistance at 20C (Ω/km) |

Approx weight of cable (kg/km) |

||

|

Cu |

Al |

Cu |

Al |

|||||

|

4X4 |

1.0 |

1.2 |

1.8 |

20.1 |

4.61 |

7.41 |

874 |

773 |

|

4X6 |

1.0 |

1.2 |

1.8 |

21.7 |

3.08 |

4.61 |

1130 |

978 |

|

4x 10 |

1.0 |

1.2 |

1.8 |

25.6 |

1.83 |

3.02 |

1515 |

1254 |

|

4x 16 |

1.0 |

1.2 |

1.8 |

28.1 |

1.15 |

1.91 |

1924 |

1502 |

|

4x25 |

1.2 |

1.2 |

2.0 |

32.7 |

0.727 |

1.20 |

2570 |

1919 |

|

4x35 |

1.2 |

1.2 |

2.1 |

35.7 |

0.524 |

0.868 |

3130 |

2227 |

|

4x50 |

1.4 |

1.2 |

2.1 |

37.2 |

0.387 |

0.641 |

3795 |

2505 |

|

4x70 |

1.4 |

1.2 |

2.3 |

41.9 |

0.268 |

0.443 |

5147 |

3342 |

|

4x95 |

1.6 |

1.3 |

2.5 |

47.9 |

0.193 |

0.320 |

6586 |

4137 |

|

4x120 |

1.6 |

1.4 |

2.6 |

53.9 |

0.153 |

0.253 |

8514 |

5420 |

|

4x150 |

1.8 |

1.4 |

2.8 |

58.4 |

0.124 |

0.206 |

10116 |

6248 |

|

4x185 |

2.0 |

1.5 |

3.0 |

63.6 |

0.0991 |

0.164 |

12007 |

7237 |

|

4x240 |

2.2 |

1.7 |

3.2 |

65.7 |

0.0754 |

0.125 |

14460 |

8271 |

|

4x300 |

2.4 |

1.8 |

3.4 |

70.7 |

0.0601 |

0.100 |

17249 |

9515 |