- ICEA S-75-381/NEMA WC 58

- ASTM B 172

- ASTM B 33

- CAN/CSA C22.2 No.96

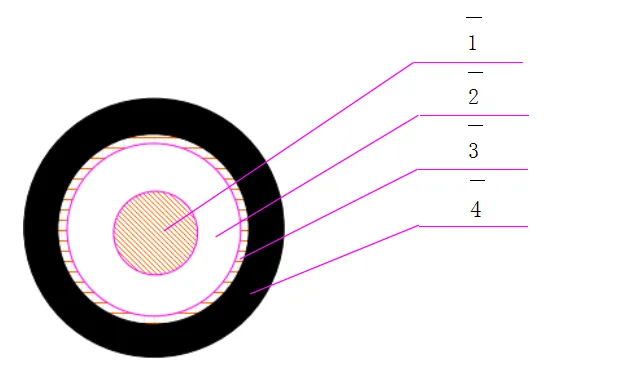

1. Stranded Tinned Copper Conductor

2. EPR Insulation

3. Reinforcement

4. CPE Jacket

- Conductors: Stranded annealed tinned copper conductor.

- Insulation: EPR.

- Reinforcement: A layer of polyester braid, applied between the insulation and sheath for mechanical strength.

- Sheath: Chlorinated Polyethylene(CPE), black. Other sheath materials/color can be offered as an option.

Other jacket materials/color such as CSP/PCP/NBR/PVC are available upon request.

Two-layer jacket with reinforcing fiber between the two layers can be offered as an option.

- Minimum Bending Radius: 6×OD

- Maximum Operating Temperature: +90℃

|

Ukwakhiwa |

No. of Strands |

Ukutyeba kwe-Insulation ye-Nominal |

Nominal Overall Diameter |

Nominal Weight |

Ampacity |

|||

|

No. of cores×AWG/kcmil |

|

intshi |

mm |

intshi |

mm |

lbs/kft |

kg/km |

A |

|

1×8 |

133 |

0.060 |

1.5 |

0.44 |

11.2 |

150 |

223 |

83 |

|

1×6 |

168 |

0.060 |

1.5 |

0.51 |

13.0 |

205 |

305 |

109 |

|

1×4 |

259 |

0.060 |

1.5 |

0.57 |

14.5 |

280 |

417 |

145 |

|

1×3 |

329 |

0.060 |

1.5 |

0.63 |

16.0 |

350 |

521 |

167 |

|

1×2 |

259 |

0.060 |

1.5 |

0.66 |

16.8 |

370 |

550 |

192 |

|

1×1 |

329 |

0.080 |

2.0 |

0.74 |

18.8 |

500 |

744 |

223 |

|

1×1/0 |

259 |

0.080 |

2.0 |

0.77 |

19.6 |

550 |

818 |

258 |

|

1×2/0 |

329 |

0.080 |

2.0 |

0.82 |

20.1 |

660 |

982 |

298 |

|

1×3/0 |

427 |

0.080 |

2.0 |

0.87 |

22.1 |

830 |

1235 |

345 |

|

1×4/0 |

532 |

0.080 |

2.0 |

0.93 |

23.6 |

950 |

1413 |

400 |

|

1×250 |

608 |

0.095 |

2.4 |

1.03 |

26.2 |

1240 |

1845 |

445 |

|

1×300 |

741 |

0.095 |

2.4 |

1.09 |

27.7 |

1400 |

2083 |

500 |

|

1×350 |

855 |

0.095 |

2.4 |

1.15 |

29.2 |

1480 |

2202 |

552 |

|

1×500 |

1221 |

0.095 |

2.4 |

1.31 |

33.3 |

2140 |

3184 |

695 |

Ampacity-Based on a conductor temperature of 90C and an ambient air temperature of 40C, per ICEA S-75-381