Nov . 07, 2024 21:38 Back to list

Understanding the Basics of PN16 Check Valve Functionality and Applications

Understanding PN16% Check Valves Essential Components in Fluid Control Systems

In the realm of fluid control systems, one of the critical components that ensure smooth operations and efficient management of pressure is the check valve. Among the various types of check valves, the PN16% check valve stands out for its specific design and operational benefits, particularly in systems where pressure and flow management are vital.

What is a Check Valve?

A check valve, also known as a non-return valve, is designed to allow fluid to flow in one direction while preventing it from flowing back in the opposite direction. This mechanism is essential in various applications, including water supply systems, sewage treatment plants, and industrial processes. Check valves are crucial in protecting pumps and other equipment from damage caused by reverse flow, which can lead to inefficiencies and costly repairs.

Understanding PN16%

The term PN stands for Pressure Nominal, which indicates the maximum pressure that a valve can withstand in bar. In the case of PN16% check valves, it signifies that these valves are rated to handle a nominal pressure of 16 bar. This rating is important as it helps engineers and designers select the appropriate components for their systems based on the expected pressure conditions.

Importance of PN16% Check Valves

1. Enhanced Reliability PN16% check valves are designed to operate under significant pressure, making them a reliable choice for various applications. Their robust construction ensures that they can handle demanding conditions without failure.

2. Prevention of Backflow One of the primary functions of check valves is to prevent backflow, which can compromise system integrity. PN16% check valves effectively seal when there is a decrease in upstream pressure, ensuring that fluids do not reverse their flow.

3. Versatility in Applications These check valves can be used in numerous applications, including water supply systems, oil and gas systems, and industrial processes. Their ability to function in various media, including liquids and gases, makes them a versatile choice for engineers.

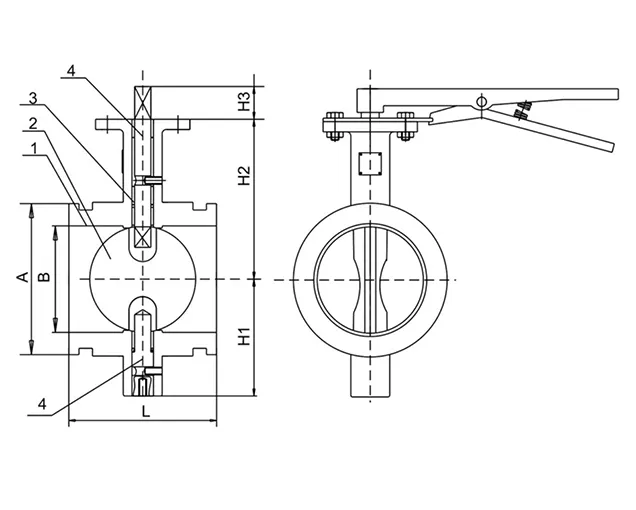

pn16 check valve

4. Cost-Effectiveness By preventing backflow and protecting downstream equipment, PN16% check valves can save organizations significant costs associated with repairs and maintenance. Their durability also ensures a longer service life, lowering replacement frequency and expenses.

5. Ease of Maintenance PN16% check valves typically have a straightforward design, making them easier to maintain and service. Regular inspections can ensure they function correctly, providing peace of mind for system operators.

Key Features of PN16% Check Valves

- Material Quality PN16% check valves are usually made from high-quality materials such as cast iron, stainless steel, or PVC, depending on the application requirements. The choice of material affects the valve’s ability to resist corrosion and wear.

- Size and Configuration These valves come in various sizes and configurations, allowing them to fit seamlessly into existing systems. Proper sizing is crucial for optimal performance, as oversized or undersized valves can lead to inefficiencies.

- Design Variations There are several design variations of check valves, including swing check valves and ball check valves. Each design has its advantages and is suited for different operational requirements. For instance, swing check valves are commonly used in systems with lower flow velocities, while ball check valves may be preferable in high-flow applications.

Conclusion

The PN16% check valve is a vital component in any fluid control system, providing essential protection against backflow and ensuring efficient operation. By understanding the characteristics and benefits of these valves, engineers can make informed decisions when designing and maintaining fluid management systems. Their reliability, versatility, and cost-effectiveness make them a preferred choice across various industries.

As technology advances and the demands for more efficient systems continue to grow, the role of PN16% check valves will undoubtedly become even more significant. By investing in quality check valves, businesses can enhance their operational efficiency, reduce maintenance costs, and ensure the longevity of their systems. Whether in industrial applications or municipal infrastructure, understanding and implementing the right check valves is crucial for optimal performance and reliability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025