Nov . 07, 2024 21:49 Back to list

Understanding the Benefits and Functionality of Double Swing Check Valves in Piping Systems

Understanding the Double Swing Check Valve A Vital Component in Fluid Systems

In the world of fluid dynamics and piping systems, valves play an essential role in regulating flow, controlling pressure, and preventing backflow. Among the various types of valves, the double swing check valve stands out for its unique design and functionality. This article will delve into the characteristics, applications, advantages, and maintenance of double swing check valves.

What is a Double Swing Check Valve?

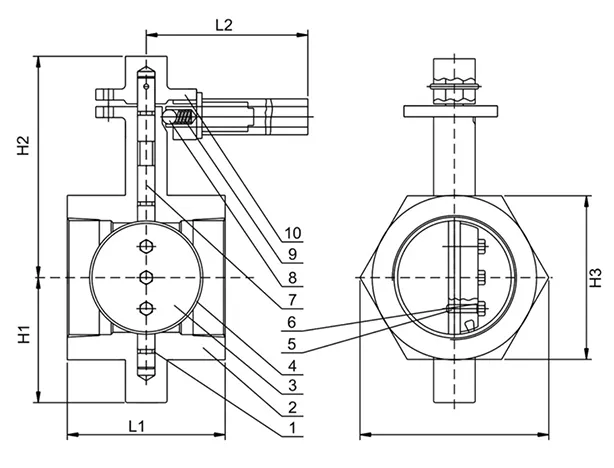

A double swing check valve is a type of non-return valve that utilizes two hinged flaps or discs that pivot on a hinge point. These discs swing open to allow fluid to pass in one direction while closing automatically when the flow reverses, effectively preventing backflow. The double swing design allows for a more efficient flow of fluids compared to traditional single disc check valves. This design minimizes pressure loss across the valve and ensures a smoother operation.

Key Features and Advantages

1. Reduced Pressure Drop One of the main advantages of double swing check valves is their ability to provide a lower pressure drop compared to other check valves. This is particularly beneficial in large-diameter pipes or systems where maintaining pressure is crucial.

2. Compact Design Double swing check valves can be more compact than their single-disc counterparts, making them easier to install in confined spaces without sacrificing performance.

3. Durability Made from robust materials like stainless steel, cast iron, or bronze, double swing check valves can withstand harsh environmental conditions, including high pressures and temperatures. Their design reduces wear and tear, ensuring a longer service life.

4. Ease of Maintenance With fewer moving parts and a simple design, double swing check valves are easier to maintain and service. This can lead to decreased downtime and lower operational costs.

5. Versatility Double swing check valves are suitable for various applications, including water supply systems, wastewater treatment, and industrial processes. They can handle various fluids, including slurries and gases, making them versatile in their use.

Applications

Double swing check valves are commonly used in a variety of industries and applications. Some of the most typical uses include

double swing check valve

- Water Treatment Plants To prevent contamination from backflow in potable water systems. - Pumping Stations To protect pumps from potential damage caused by reverse flow. - Oil and Gas Industry To ensure safety and reliability in the transportation of fluids. - Chemical Processing To prevent the backflow of hazardous materials in processing lines.

Installation Considerations

When installing a double swing check valve, it’s crucial to consider the following factors

1. Optimal Orientation These valves should be installed in a horizontal or vertical position based on the system design to ensure proper functioning. 2. Pipe Size Compatibility Ensuring that the valve matches the diameter of the connecting pipes is essential for maintaining efficiency and avoiding turbulence.

3. Flow Direction Marking the flow direction on the valve itself can prevent installation errors that could compromise the system's integrity.

Maintenance Tips

Regular maintenance of double swing check valves can prolong their lifespan and enhance performance. Here are a few tips

1. Routine Inspections Regularly check for signs of wear, corrosion, or sediment buildup around the valve.

2. Cleaning Ensure that the valve is free from debris and other obstructions that could hinder its operation.

3. Functional Testing Periodically test the valve by observing its response to simulated reverse flow conditions to ensure it seals properly.

Conclusion

The double swing check valve is an indispensable component in various fluid handling systems, providing reliability and efficiency. Its unique design minimizes pressure loss, enhances flow capacity, and ensures the safety of the overall system. Understanding its features, applications, and maintenance is essential for engineers and maintenance personnel to optimize the use of this vital valve in their operations.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025