Feb . 10, 2025 23:03 Back to list

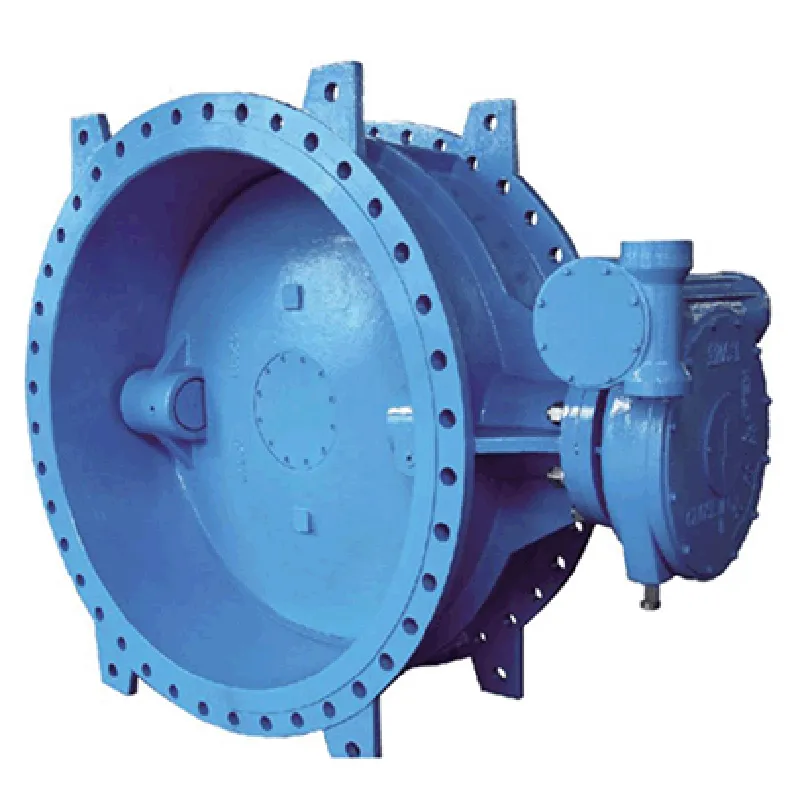

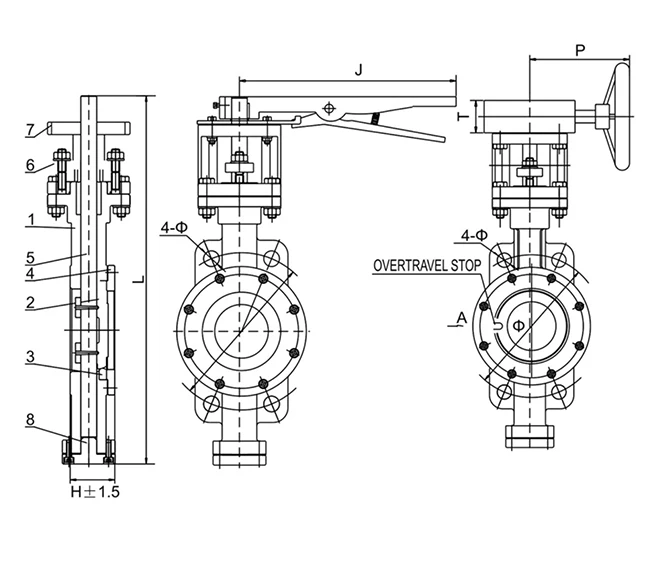

Grooved End Butterfly Valve

Finding the perfect valve solution is crucial for industries that rely on fluid management, whether it be in HVAC systems, water treatment facilities, or industrial processes. One valve technology that has gained significant traction due to its unique construction and efficiency is the grooved end butterfly valve. While these valves are pivotal in various applications, a deeper appreciation of their design and advantages can aid in selecting the right solution.

Reliable sealing capability is a core attribute of grooved end butterfly valves, which makes them an ideal choice for preventing leakage. In systems where leak tightness is paramount, these valves can be equipped with bubble-tight shut-off features. This reliability is foundational in industries such as water treatment, where every drop matters, and consistent performance is non-negotiable. In addressing the environmental and operational demands of modern industries, the role of innovation in valve design cannot be understated. Grooved end butterfly valves stand as a testament to the progress made in engineering fluid control solutions that are not just functional but also sustainable. These valves minimize material use during manufacturing and streamline installation procedures, contributing to more environmentally friendly operations. Safety is another critical factor that reinforces the utility of grooved end butterfly valves. The simplicity of the design and the robustness of their components mean fewer points of failure, thereby minimizing the risk of system faults. Businesses report fewer incidents of leakage and emergency interventions, which instills a higher level of trust in these valves for daily operations and critical applications. Making the right choice in valve solutions is about striking a balance between operational efficiency, cost-effectiveness, and reliability. Grooved end butterfly valves illustrate an optimal choice for many because they do not compromise on quality or performance. As businesses and industries continue evolving, such valve technologies are anticipated to play an integral role in redefining efficiency standards and operational excellence. For those in pursuit of a valve solution that champions innovation, ease of installation, and long-term reliability, grooved end butterfly valves represent a perfect amalgamation of historical expertise and modern engineering. Their adoption signifies a commitment to quality and sustainability, which ultimately drives better business outcomes and prepares industries for the demands of the future.

Reliable sealing capability is a core attribute of grooved end butterfly valves, which makes them an ideal choice for preventing leakage. In systems where leak tightness is paramount, these valves can be equipped with bubble-tight shut-off features. This reliability is foundational in industries such as water treatment, where every drop matters, and consistent performance is non-negotiable. In addressing the environmental and operational demands of modern industries, the role of innovation in valve design cannot be understated. Grooved end butterfly valves stand as a testament to the progress made in engineering fluid control solutions that are not just functional but also sustainable. These valves minimize material use during manufacturing and streamline installation procedures, contributing to more environmentally friendly operations. Safety is another critical factor that reinforces the utility of grooved end butterfly valves. The simplicity of the design and the robustness of their components mean fewer points of failure, thereby minimizing the risk of system faults. Businesses report fewer incidents of leakage and emergency interventions, which instills a higher level of trust in these valves for daily operations and critical applications. Making the right choice in valve solutions is about striking a balance between operational efficiency, cost-effectiveness, and reliability. Grooved end butterfly valves illustrate an optimal choice for many because they do not compromise on quality or performance. As businesses and industries continue evolving, such valve technologies are anticipated to play an integral role in redefining efficiency standards and operational excellence. For those in pursuit of a valve solution that champions innovation, ease of installation, and long-term reliability, grooved end butterfly valves represent a perfect amalgamation of historical expertise and modern engineering. Their adoption signifies a commitment to quality and sustainability, which ultimately drives better business outcomes and prepares industries for the demands of the future.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025