Jan . 24, 2025 01:02 Back to list

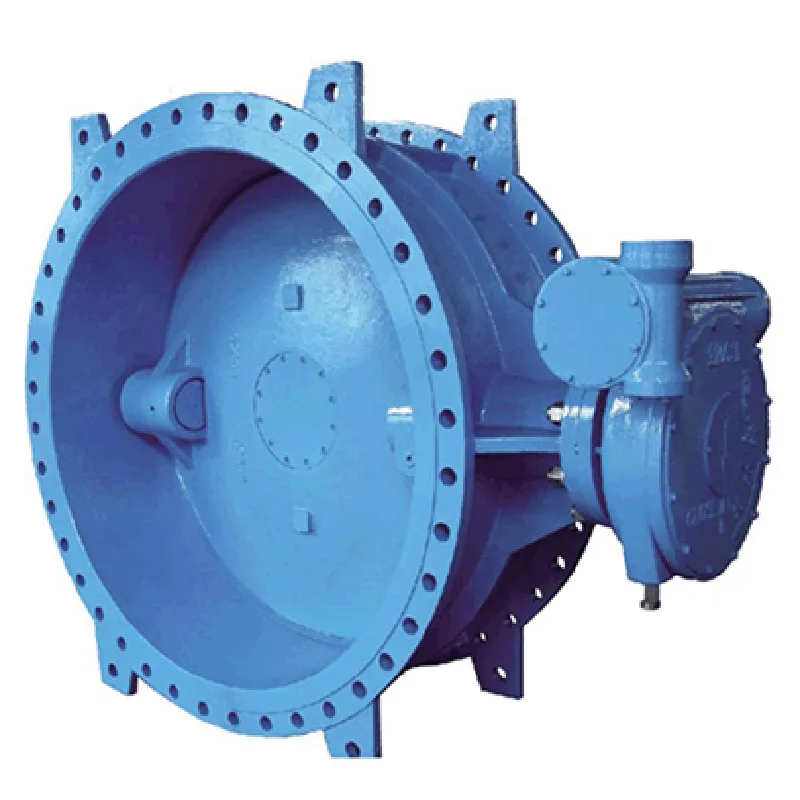

dismantling joint

Dismantling joint components can be a meticulous process, especially if you're dealing with complex machinery or delicate equipment. From an experiential standpoint, this task often requires not just dexterity but a profound understanding of the component's design and functionality. Imagine working within a high-stakes environment where precision is not just recommended but mandatory. It's about turning theory into practice with expertise that has been honed over years of hands-on work.

Trustworthiness in dismantling joint operations is built on transparency and quality assurance. Professionals in the field often provide their clients with step-by-step walkthroughs of the process, detailing each component's condition upon disassembly and recommending appropriate follow-up actions. This might include suggesting OEM replacements when necessary, ensuring that reassembly does not compromise the system's functionality. By doing so, technicians foster trust with their clients, who can rely on expert assessments that prioritize system longevity and safety over quick fixes or cost-cutting measures. In terms of practical guidance for those seeking to optimize their dismantling processes, it is beneficial to invest in state-of-the-art tools and technologies, such as thermal imaging for detecting joint temperatures or ultrasonic testing for identifying seamless component integrity. Moreover, committing to continuous education through certifications and workshops can significantly enhance one's competency in handling more advanced systems, thus leading to more innovative solutions and increased client satisfaction. Ultimately, the art and science of dismantling joint components converge through a commitment to excellence. With the correct blend of experience, specialized knowledge, authoritative protocol adherence, and trustworthy operations, one can achieve not just efficiency but also contribute to the broader discourse on responsible engineering practices. As industries evolve, adapting and elevating these competencies will remain a necessary pillar for success in the realm of mechanical and structural assemblies.

Trustworthiness in dismantling joint operations is built on transparency and quality assurance. Professionals in the field often provide their clients with step-by-step walkthroughs of the process, detailing each component's condition upon disassembly and recommending appropriate follow-up actions. This might include suggesting OEM replacements when necessary, ensuring that reassembly does not compromise the system's functionality. By doing so, technicians foster trust with their clients, who can rely on expert assessments that prioritize system longevity and safety over quick fixes or cost-cutting measures. In terms of practical guidance for those seeking to optimize their dismantling processes, it is beneficial to invest in state-of-the-art tools and technologies, such as thermal imaging for detecting joint temperatures or ultrasonic testing for identifying seamless component integrity. Moreover, committing to continuous education through certifications and workshops can significantly enhance one's competency in handling more advanced systems, thus leading to more innovative solutions and increased client satisfaction. Ultimately, the art and science of dismantling joint components converge through a commitment to excellence. With the correct blend of experience, specialized knowledge, authoritative protocol adherence, and trustworthy operations, one can achieve not just efficiency but also contribute to the broader discourse on responsible engineering practices. As industries evolve, adapting and elevating these competencies will remain a necessary pillar for success in the realm of mechanical and structural assemblies.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025