ม.ค. . 20, 2025 08:51 Back to list

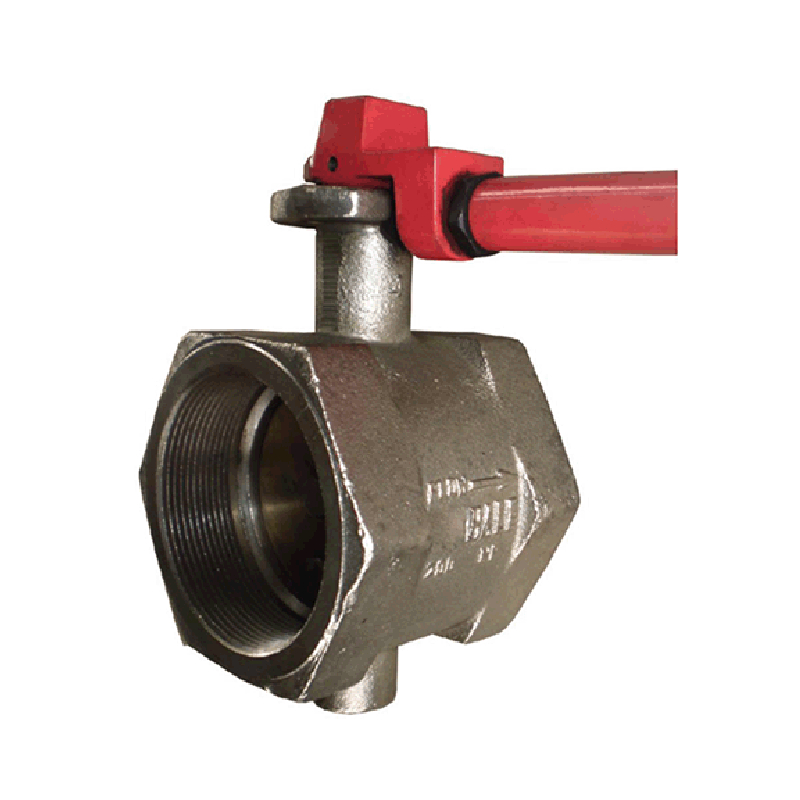

ball type check valve

The electronic ball valve has revolutionized control systems in various industrial applications, offering unparalleled precision and convenience. Imagine managing your fluid flow systems with the ease of a button press or a computer command. This technology represents a leap forward, combining the traditional mechanics of ball valves with cutting-edge electronics for enhanced functionality.

When discussing authority, the high level of control and precision offered by these valves aligns with stringent industry standards and regulations. In sectors where precision is mandatory, such as pharmaceuticals and food processing, electronic ball valves ensure compliance while maintaining product quality and safety. As for trustworthiness, these valves have been rigorously tested across multiple environments to confirm their durability and reliability. Constructed from robust materials, such as stainless steel or brass, electronic ball valves withstand harsh conditions, providing consistent performance over time. Their low maintenance requirements further underline their dependability, reducing the total cost of ownership for operators. The integration of electronic ball valves into industrial and commercial applications symbolizes a commitment to technological progress and efficiency. By elevating the level of control, fostering compliance with regulations, and reducing operational costs through lower maintenance needs, electronic ball valves are a testament to modern engineering prowess. In conclusion, the electronic ball valve is more than just an upgraded component; it represents a strategic asset for industries seeking to enhance their operational capabilities. With its precision, adaptability, reliability, and cost-efficiency, the electronic ball valve is poised to continue transforming fluid management systems, driving innovation, and maintaining its pivotal role in the world of industrial fluid control.

When discussing authority, the high level of control and precision offered by these valves aligns with stringent industry standards and regulations. In sectors where precision is mandatory, such as pharmaceuticals and food processing, electronic ball valves ensure compliance while maintaining product quality and safety. As for trustworthiness, these valves have been rigorously tested across multiple environments to confirm their durability and reliability. Constructed from robust materials, such as stainless steel or brass, electronic ball valves withstand harsh conditions, providing consistent performance over time. Their low maintenance requirements further underline their dependability, reducing the total cost of ownership for operators. The integration of electronic ball valves into industrial and commercial applications symbolizes a commitment to technological progress and efficiency. By elevating the level of control, fostering compliance with regulations, and reducing operational costs through lower maintenance needs, electronic ball valves are a testament to modern engineering prowess. In conclusion, the electronic ball valve is more than just an upgraded component; it represents a strategic asset for industries seeking to enhance their operational capabilities. With its precision, adaptability, reliability, and cost-efficiency, the electronic ball valve is poised to continue transforming fluid management systems, driving innovation, and maintaining its pivotal role in the world of industrial fluid control.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025