Novemba . 12, 2024 12:27 Back to list

wafer type butterfly valve flange

Understanding Wafer Type Butterfly Valves and Their Flanges

Wafer type butterfly valves are critical components in various industrial systems, particularly in fluid control applications. Their design is efficient and increasingly popular in both new installations and retrofitting existing systems. This article aims to explore the intricacies of wafer type butterfly valves, their flanges, and the advantages they bring to various industries.

What is a Wafer Type Butterfly Valve?

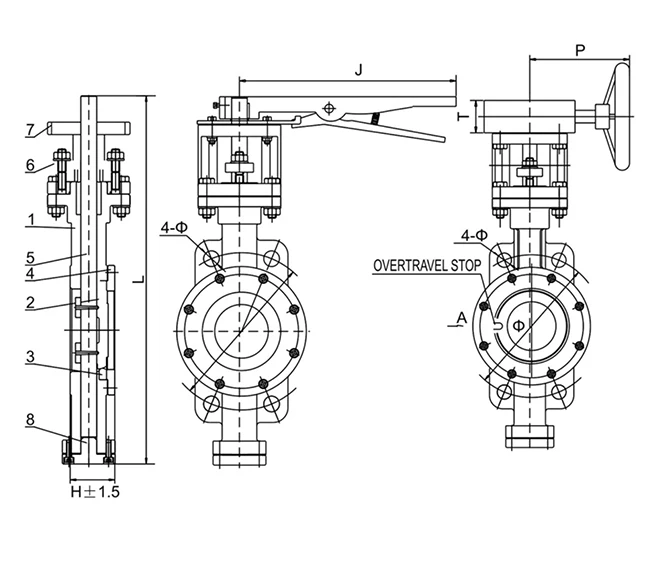

A wafer type butterfly valve consists of a circular disc that rotates around a central axis to regulate the flow of fluids. Unlike traditional valve designs that require extensive space, wafer type butterfly valves are uniquely engineered for a more compact footprint, allowing them to fit snugly between two flanges without additional support structures. This design minimizes the space required, making them ideal for limited spaces in piping systems.

The Importance of Flanges

Flanges are critical components of any valve system, as they provide the means to attach the valve securely to the piping. In the case of wafer type butterfly valves, the design features a flat-faced flange that lies between two pipe flanges. This setup not only ensures a tight seal but also facilitates easier installation and maintenance. The flanges in these systems must meet specific standards, such as ANSI, ASME, or DIN, to ensure compatibility with various piping systems and to maintain integrity under pressure.

Advantages of Wafer Type Butterfly Valves

1. Space Efficiency One of the most significant advantages of wafer type butterfly valves is their compact nature. Because they do not require external supports or a lot of space, they can be fitted into tight configurations without compromising flow quality.

wafer type butterfly valve flange

2. Weight Savings Compared to traditional valve designs, wafer type butterfly valves are generally lighter and easier to handle. This weight saving translates into lower transportation and installation costs.

3. Cost-Effectiveness In terms of material usage and manufacturing processes, wafer type butterfly valves are often less expensive to produce than their counterparts. This economic aspect makes them a popular choice in industrial applications where cost efficiency is crucial.

4. Ease of Operation The design of the valve allows for quick operation, enabling rapid changes in flow control with minimal manual effort. This ease of operation is especially beneficial in applications requiring frequent flow adjustments.

5. Versatility Wafer type butterfly valves are suitable for various applications, including water treatment, HVAC systems, and chemical processing. They can manage different types of fluids, including slurries, gases, and liquids, making them versatile tools across multiple industries.

Applications in Industries

The versatility of wafer type butterfly valves extends to numerous industries. In water treatment facilities, they control the flow of water, ensuring efficient processing. HVAC systems rely on these valves for regulating airflow, making them essential for maintaining indoor climate control. In chemical processing plants, their ability to handle corrosive fluids while providing robust sealing capabilities is invaluable.

Conclusion

Wafer type butterfly valves, paired with appropriately designed flanges, represent a modern solution for fluid control challenges across various industries. Their compact size, weight efficiency, cost-effectiveness, ease of operation, and adaptability make them a favored choice for engineers and system designers alike. As industries continue to seek improved efficiency and reliability in fluid management, the importance of innovative solutions like wafer type butterfly valves will undoubtedly grow, solidifying their role in contemporary engineering applications. By investing in these advanced valve systems, companies can ensure that they optimize their operations while maintaining the highest standards of safety and performance.

Share