Mei . 29, 2025 13:46 Rudi kwenye orodha

Industrial Gate Valve

Gate valves are essential components in various industrial applications, providing reliable and efficient flow control. In this article, we will explore five popular types of gate valves and related products: industrial gate valve, gate valve actuator, double flanged gate valve, ansi gate valve, and ductile iron gate valve. Each type offers unique features and benefits to suit different needs and preferences.

Gate Valve Actuator: Automated Control and Efficiency

The gate valve actuator is a critical component that provides automated control for gate valves. This type of actuator allows for precise and efficient operation of the valve, reducing the need for manual intervention. Gate valve actuators are available in various types, including electric, pneumatic, and hydraulic, each offering different benefits depending on the application. They are commonly used in industrial processes where automated control is essential for maintaining process efficiency and safety.

Industrial Gate Valve: Robust and Reliable Flow Control

The industrial gate valve is a robust and reliable solution for flow control in various industrial applications. This type of valve is designed to provide efficient and precise control over fluid flow, ensuring smooth operation and minimal maintenance. Industrial gate valves are commonly used in water treatment, oil and gas, petrochemical, and power generation industries. They are available in various sizes and materials to meet specific requirements.

Double Flanged Gate Valve: Secure and Stable Connections

The double flanged gate valve is designed to provide secure and stable connections in pipe systems. This type of valve features double flanges that ensure a tight seal and reliable connection, making it ideal for applications where high pressure and flow rates are involved. Double flanged gate valves are commonly used in oil and gas, petrochemical, and water treatment industries. They are available in various sizes and materials to meet specific requirements.

ANSI Gate Valve: Standardized and Reliable

The ansi gate valve is designed to meet the standards set by the American National Standards Institute (ANSI). This type of valve ensures high-quality performance and reliability, making it ideal for various industrial applications. ANSI gate valves are available in different pressure classes and materials, ensuring compatibility with a wide range of systems. They are commonly used in oil and gas, petrochemical, and power generation industries, where adherence to strict standards is crucial.

Ductile Iron Gate Valve: Durability and Corrosion Resistance

The ductile iron gate valve is designed to provide durable and corrosion-resistant flow control. Made from high-quality ductile iron, this type of valve is ideal for applications where exposure to corrosive fluids is a concern. Ductile iron gate valves offer excellent strength and reliability, making them suitable for water treatment, sewage systems, and other industrial applications. They are available in various sizes and configurations to meet specific requirements.

Industrial Gate Valve FAQs

What are the benefits of using an Industrial Gate Valve?

The industrial gate valve offers robust and reliable flow control, ensuring efficient and precise operation. It is available in various sizes and materials, making it suitable for a wide range of industrial applications.

Where can I find a Gate Valve Actuator?

You can find a gate valve actuator at specialized industrial suppliers or online stores. When selecting an actuator, consider factors such as type (electric, pneumatic, hydraulic), pressure rating, and specific application requirements.

What are the common applications of a Double Flanged Gate Valve?

The double flanged gate valve is commonly used in oil and gas, petrochemical, and water treatment industries. Its double flanges ensure secure and stable connections, making it ideal for high-pressure and high-flow applications.

How does an ANSI Gate Valve ensure reliability?

The ansi gate valve ensures reliability by adhering to the standards set by the American National Standards Institute (ANSI). It is available in different pressure classes and materials, ensuring compatibility with a wide range of industrial systems.

Why is a Ductile Iron Gate Valve considered durable?

The ductile iron gate valve is considered durable due to its high-quality material, which offers excellent strength and corrosion resistance. It is ideal for applications in water treatment, sewage systems, and other industrial processes where reliability is crucial.

Thank you for exploring the world of industrial gate valve solutions. We hope this article has provided valuable insights into the features and benefits of these essential components. For more information, please refer to the product catalogs or contact your nearest supplier.

Shiriki

Septemba . 05, 2024 12:30 Rudi kwenye orodha

Industrial Gate Valve - High-Quality Performance and Durability

Understanding Industrial Gate Valves Essential Components for Fluid Control

Industrial gate valves are critical components in various fluid control systems, serving a pivotal role in the regulation of liquid and gas flow in numerous applications. These valves are designed to provide maximum flow with minimal pressure drop, making them ideal for use in pipelines that require either complete shut-off or full flow.

Understanding Industrial Gate Valves Essential Components for Fluid Control

Gate valves come in various designs and materials, catering to the specific requirements of different industries. Common materials used include cast iron, stainless steel, and bronze, each chosen for their durability and resistance to corrosion. The selection of material is often influenced by factors such as fluid type, operating temperature, and pressure levels. Additionally, gate valves can be configured in several ways, including rising stem and non-rising stem designs, allowing for flexibility in installation and usage.

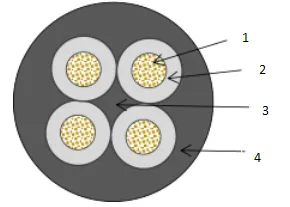

industrial gate valve

One of the primary advantages of gate valves is their durability and longevity. They are built to withstand harsh conditions, making them ideal for industries such as oil and gas, chemical processing, and water treatment. Furthermore, they require minimal maintenance, which is a critical consideration in industrial applications where downtime can be costly.

However, it's important to note that gate valves are not suitable for throttling services. Their design is intended for either full open or fully closed positions, and using them for flow regulation can lead to erosion and damage. For such purposes, other valve types, like globe valves or ball valves, are recommended.

In summary, industrial gate valves are essential components in many fluid control systems. Their ability to provide a reliable and efficient means of controlling flow makes them indispensable in various sectors, from manufacturing to utility services. Understanding the design, materials, and appropriate applications of gate valves is crucial for ensuring optimal performance and longevity in industrial operations. As industries continue to evolve, the role of gate valves will remain fundamental in the quest for efficient and effective fluid management solutions.

Shiriki