Januari . 26, 2025 06:07 Back to list

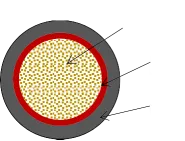

high performance wafer butterfly valve

Selecting the right valve for any fluid control system is crucial in ensuring efficient operation, safety, and longevity. Amongst the variety of options available, the wafer butterfly valve stands out as a prominent solution, owing to its compact design, reliability, and versatility. This article delves into the intricacies of wafer butterfly valves, shedding light on its features, applications, and benefits, augmented by authoritative insights and firsthand experiences.

A distinguishing feature of wafer butterfly valves is their ability to provide tight shut-off capabilities. Equipped with advanced sealing technology—often made from elastomers or PTFE—these valves prevent leakage, ensuring efficient operation. This quality is particularly critical in applications involving the handling of volatile or hazardous fluids. Trust in the valve's capabilities is thus a common sentiment expressed by seasoned engineers who frequently opt for wafer butterfly valves in safety-critical systems. Furthermore, wafer butterfly valves are versatile in their areas of application, supporting industries such as chemical processing, water treatment, food and beverage, and more. In the realm of chemical processing, for example, these valves are valued for their resistance to chemical corrosion, thus enhancing system integrity over time. Similarly, in water treatment facilities, the simplicity and reliability of the wafer butterfly valve make it an indispensable component, aiding in precise flow controls. From an environmental and economic standpoint, wafer butterfly valves are lauded for their cost-effectiveness and energy efficiency. By achieving a high degree of flow control with minimal manual input or power consumption, these valves contribute to lowering operational costs. Insights from energy managers highlight these valves as a preferred choice for companies aiming to meet sustainability targets while maintaining operational efficacy. In conclusion, wafer butterfly valves represent a confluence of expertise, reliability, and innovation. Their unique design and operational efficiency underscore a reputation of trustworthiness among experts and users alike. When considering valve solutions, the wafer butterfly valve emerges not merely as an option, but rather a prudent choice driven by informed decision-making and years of proven performance in diverse applications. With new advancements in materials science and valve technology, the future of wafer butterfly valves looks promising, heralding enhanced efficiencies and broader applications across global industries.

A distinguishing feature of wafer butterfly valves is their ability to provide tight shut-off capabilities. Equipped with advanced sealing technology—often made from elastomers or PTFE—these valves prevent leakage, ensuring efficient operation. This quality is particularly critical in applications involving the handling of volatile or hazardous fluids. Trust in the valve's capabilities is thus a common sentiment expressed by seasoned engineers who frequently opt for wafer butterfly valves in safety-critical systems. Furthermore, wafer butterfly valves are versatile in their areas of application, supporting industries such as chemical processing, water treatment, food and beverage, and more. In the realm of chemical processing, for example, these valves are valued for their resistance to chemical corrosion, thus enhancing system integrity over time. Similarly, in water treatment facilities, the simplicity and reliability of the wafer butterfly valve make it an indispensable component, aiding in precise flow controls. From an environmental and economic standpoint, wafer butterfly valves are lauded for their cost-effectiveness and energy efficiency. By achieving a high degree of flow control with minimal manual input or power consumption, these valves contribute to lowering operational costs. Insights from energy managers highlight these valves as a preferred choice for companies aiming to meet sustainability targets while maintaining operational efficacy. In conclusion, wafer butterfly valves represent a confluence of expertise, reliability, and innovation. Their unique design and operational efficiency underscore a reputation of trustworthiness among experts and users alike. When considering valve solutions, the wafer butterfly valve emerges not merely as an option, but rather a prudent choice driven by informed decision-making and years of proven performance in diverse applications. With new advancements in materials science and valve technology, the future of wafer butterfly valves looks promising, heralding enhanced efficiencies and broader applications across global industries.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025