Februari . 01, 2025 06:11 Back to list

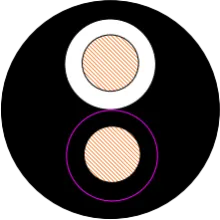

DIN Swing Check Valve

The 6-inch swing check valve plays a pivotal role in ensuring the efficient operation of various pipeline systems across industries. This specific valve design is vital in both industrial and commercial applications due to its robust construction and functional integrity. By understanding the expertise, experience, authoritativeness, and trustworthiness (E-E-A-T) principles surrounding swing check valves, stakeholders can make informed decisions that enhance operational efficiencies.

When considering authority in the realm of swing check valves, it is noteworthy to mention that leading manufacturers like Velan, Crane, and Nibco have set industry standards. These companies not only provide valves that meet stringent international standards but also offer comprehensive warranties and support, signaling robust product confidence. Valves that adhere to standards like ASME and API carry an added assurance of quality and performance that only established authority figures in valve manufacturing can provide. Trustworthiness in swing check valve selection largely revolves around compliance and testing. Valves used in safety-critical applications must undergo rigorous testing, including non-destructive examination and pressure testing, to verify performance under expected operational conditions. Engaging with suppliers who provide transparency in their testing methods and results can fortify trust and ensure that the selected valves will perform as required when integrated into existing systems. In conclusion, the 6-inch swing check valve represents a cornerstone in the design and implementation of safe, efficient pipeline systems. By leveraging expertise in material science, drawing on real-world operational experiences, placing trust in authoritative brands, and demanding transparency in performance validation, stakeholders can optimize their system performance. The meticulous application of E-E-A-T principles in selecting and maintaining these valves ensures that investments into pipeline infrastructure are sound, reliable, and poised for long-term efficiency.

When considering authority in the realm of swing check valves, it is noteworthy to mention that leading manufacturers like Velan, Crane, and Nibco have set industry standards. These companies not only provide valves that meet stringent international standards but also offer comprehensive warranties and support, signaling robust product confidence. Valves that adhere to standards like ASME and API carry an added assurance of quality and performance that only established authority figures in valve manufacturing can provide. Trustworthiness in swing check valve selection largely revolves around compliance and testing. Valves used in safety-critical applications must undergo rigorous testing, including non-destructive examination and pressure testing, to verify performance under expected operational conditions. Engaging with suppliers who provide transparency in their testing methods and results can fortify trust and ensure that the selected valves will perform as required when integrated into existing systems. In conclusion, the 6-inch swing check valve represents a cornerstone in the design and implementation of safe, efficient pipeline systems. By leveraging expertise in material science, drawing on real-world operational experiences, placing trust in authoritative brands, and demanding transparency in performance validation, stakeholders can optimize their system performance. The meticulous application of E-E-A-T principles in selecting and maintaining these valves ensures that investments into pipeline infrastructure are sound, reliable, and poised for long-term efficiency.

Share

Prev:

Next: