Februari . 14, 2025 06:45 Back to list

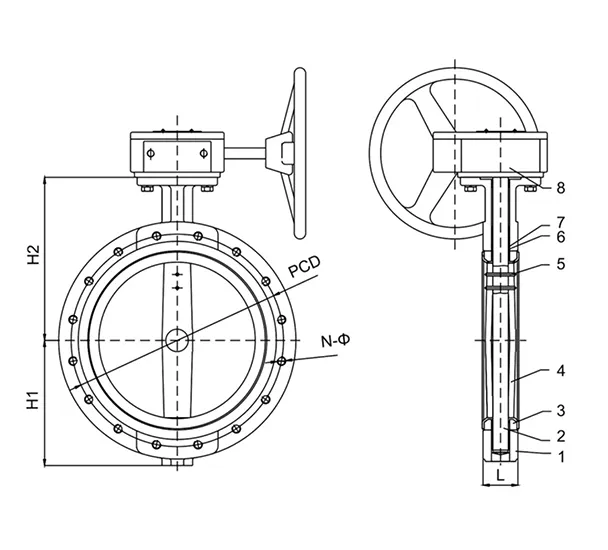

rubber lined butterfly valve

Rubber lined butterfly valves have emerged as a pivotal component in fluid control systems across various industries, celebrated not only for their simplicity but also for their ability to perform under diverse conditions. These valves provide an effective solution for controlling the flow of liquids and gases, wrapping a blend of efficiency and reliability that resonates with both novice and seasoned professionals. Through this exploration of rubber lined butterfly valves, we uncover their unique features, applications, and the expertise behind their impeccable performance.

From a trustworthiness perspective, the production of rubber lined butterfly valves adheres strictly to international protocols and certifications, such as ISO and ANSI standards. This compliance ensures that products are consistently reliable, offering predictability in performance that is crucial for maintaining process integrity in sensitive applications. Users can thus wield confidence in deploying these valves as integral components of their systems, backed by robust warranties and support services that reflect the manufacturers’ commitment to quality. In terms of real-world experience, testimonials from engineers and technicians often highlight the valve's user-friendly nature and effectiveness. Common acclaim centers around their straightforward installation—thanks to standardized dimensions and reduced weight compared to other valve types—and the ease with which they can be repaired or replaced. Such practical advantages cannot be overstated in environments where downtime equates to significant financial loss. Moreover, expert analysis frequently underscores the cost-effectiveness of rubber lined butterfly valves as a strong point of appeal. The reduced need for maintenance, coupled with the valve's durability in adverse conditions, positions it as a long-term investment rather than an operational expense. This ideal balance of upfront and lifecycle costs reinforces their stand as a preferred choice for project managers and procurement specialists aiming to optimize budget allocations without compromising on quality and performance. To sum up, rubber lined butterfly valves embody a blend of innovative design, material science, and industry expertise. Their capacity to deliver consistent performance, coupled with a wide range of applications and integration possibilities, ensures they remain a cornerstone in fluid control systems. This harmony of elements not only enhances their credibility as a reliable component but also secures their place as an indispensable tool in the ever-evolving landscape of industrial applications.

From a trustworthiness perspective, the production of rubber lined butterfly valves adheres strictly to international protocols and certifications, such as ISO and ANSI standards. This compliance ensures that products are consistently reliable, offering predictability in performance that is crucial for maintaining process integrity in sensitive applications. Users can thus wield confidence in deploying these valves as integral components of their systems, backed by robust warranties and support services that reflect the manufacturers’ commitment to quality. In terms of real-world experience, testimonials from engineers and technicians often highlight the valve's user-friendly nature and effectiveness. Common acclaim centers around their straightforward installation—thanks to standardized dimensions and reduced weight compared to other valve types—and the ease with which they can be repaired or replaced. Such practical advantages cannot be overstated in environments where downtime equates to significant financial loss. Moreover, expert analysis frequently underscores the cost-effectiveness of rubber lined butterfly valves as a strong point of appeal. The reduced need for maintenance, coupled with the valve's durability in adverse conditions, positions it as a long-term investment rather than an operational expense. This ideal balance of upfront and lifecycle costs reinforces their stand as a preferred choice for project managers and procurement specialists aiming to optimize budget allocations without compromising on quality and performance. To sum up, rubber lined butterfly valves embody a blend of innovative design, material science, and industry expertise. Their capacity to deliver consistent performance, coupled with a wide range of applications and integration possibilities, ensures they remain a cornerstone in fluid control systems. This harmony of elements not only enhances their credibility as a reliable component but also secures their place as an indispensable tool in the ever-evolving landscape of industrial applications.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025