Februari . 06, 2025 02:47 Back to list

di pipe joint type

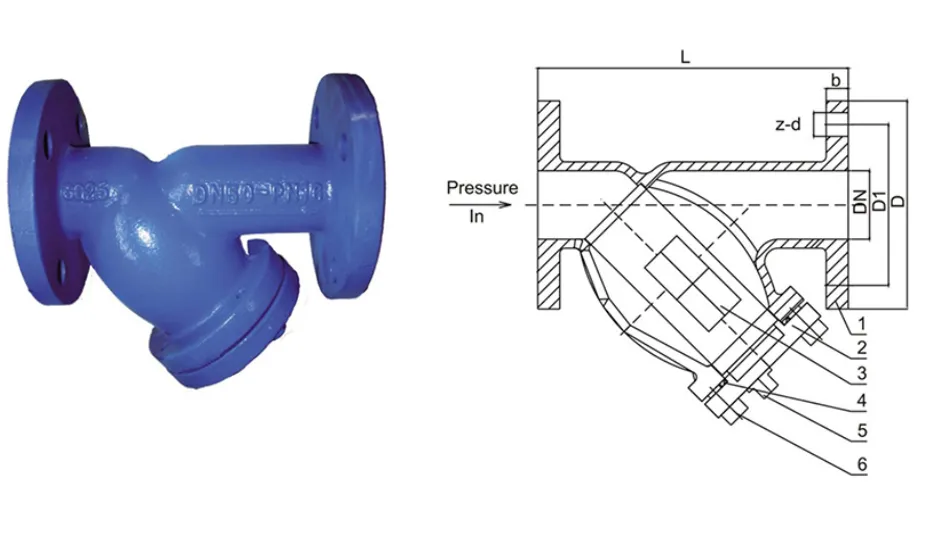

Flange dismantling joints are essential components in piping systems, specifically designed to ease the installation and maintenance processes. As a seasoned engineer with years of experience in the field, I have witnessed firsthand the profound impact these joints can have on streamlining operations in various industrial applications. Whether utilized in water treatment facilities, petrochemical plants, or power generation, flange dismantling joints offer both flexibility and reliability, crucial for maintaining system integrity and function.

From an authority standpoint, it is critical to ensure that these components comply with industry standards such as the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO). These certifications not only guarantee product quality but also affirm the manufacturer’s commitment to producing reliable and durable components. Partnering with reputable manufacturers that adhere to these standards ensures that the dismantling joints will perform effectively and safely over their intended lifespan. Trustworthiness in dismantling joint applications not only comes from the product itself but also from the installation and maintenance practices. Proper installation is paramount; a misaligned or improperly affixed joint can lead to leaks or failures. Regular maintenance checks are advisable to detect any early signs of wear and tear or potential misalignment. Engaging experienced professionals to perform these inspections can greatly minimize the risk of unexpected breakdowns and extend the life of the joint and the entire piping system. In conclusion, flange dismantling joints are indispensable components in efficient and resilient piping systems. With their ability to accommodate alignment discrepancies and environmental stressors, they are fundamental to maintaining operational continuity. By understanding the nuances of material selection, compliance with authoritative standards, and adherence to vigilant maintenance protocols, businesses can leverage these joints to enhance system reliability and efficiency. As an expert in this field, I advocate for a comprehensive approach that encompasses product quality, expert installation, periodic maintenance, and adherence to best practices, all of which contribute to a seamless and durable piping infrastructure.

From an authority standpoint, it is critical to ensure that these components comply with industry standards such as the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO). These certifications not only guarantee product quality but also affirm the manufacturer’s commitment to producing reliable and durable components. Partnering with reputable manufacturers that adhere to these standards ensures that the dismantling joints will perform effectively and safely over their intended lifespan. Trustworthiness in dismantling joint applications not only comes from the product itself but also from the installation and maintenance practices. Proper installation is paramount; a misaligned or improperly affixed joint can lead to leaks or failures. Regular maintenance checks are advisable to detect any early signs of wear and tear or potential misalignment. Engaging experienced professionals to perform these inspections can greatly minimize the risk of unexpected breakdowns and extend the life of the joint and the entire piping system. In conclusion, flange dismantling joints are indispensable components in efficient and resilient piping systems. With their ability to accommodate alignment discrepancies and environmental stressors, they are fundamental to maintaining operational continuity. By understanding the nuances of material selection, compliance with authoritative standards, and adherence to vigilant maintenance protocols, businesses can leverage these joints to enhance system reliability and efficiency. As an expert in this field, I advocate for a comprehensive approach that encompasses product quality, expert installation, periodic maintenance, and adherence to best practices, all of which contribute to a seamless and durable piping infrastructure.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025