Februari . 18, 2025 02:04 Back to list

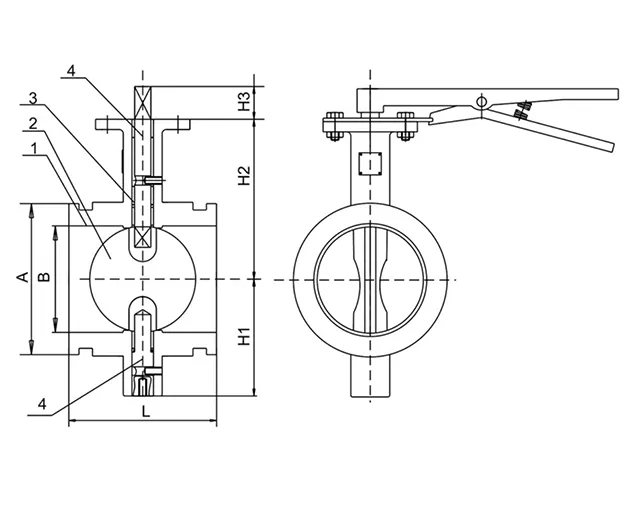

Wafer Type Butterfly Valve

For anyone seeking to optimize their HVAC systems or ensure the seamless operation of pipelines, the DI air valve emerges as an indispensable component. Standing for Differential Industrial air valve, this product is essential in guaranteeing efficiency, longevity, and reliability in various industrial applications.

For businesses looking to enhance their systems' efficiency, investing in DI air valves is a decision rooted in financial wisdom. Over time, the cost-saving benefits from preventing system downtime and maintaining efficient operations outweigh the initial investment. Furthermore, with cutting-edge technology integrated into these valves, businesses are assured of minimal maintenance requirements, thus reducing the long-term upkeep costs. It is essential for industries to understand the specific needs of their systems when selecting a DI air valve. With various models available, including automatic, vacuum, and combination air release valves, choosing the right type is critical. Engaging with industry experts or consulting valve manufacturers can ensure that the selection is tailored to the specific demands of one's operational environment. The expert knowledge in this domain emphasizes that without the strategic integration of these valves, systems are susceptible to inefficiencies and failures that could have been otherwise avoided. It is this understanding that showcases the authority and trustworthiness of advice regarding the implementation of DI air valves. In summary, the DI air valve is more than just a product; it is an investment in reliability and efficiency across multiple industrial landscapes. With its expertise-enriched design and authoritative presence across different sectors, it promises to be a trusted ally for any business aspiring to optimize its operational processes. Trust in the DI air valve is a testament to intelligent engineering, and its increasing deployment speaks volumes of its indispensable role in modern industry.

For businesses looking to enhance their systems' efficiency, investing in DI air valves is a decision rooted in financial wisdom. Over time, the cost-saving benefits from preventing system downtime and maintaining efficient operations outweigh the initial investment. Furthermore, with cutting-edge technology integrated into these valves, businesses are assured of minimal maintenance requirements, thus reducing the long-term upkeep costs. It is essential for industries to understand the specific needs of their systems when selecting a DI air valve. With various models available, including automatic, vacuum, and combination air release valves, choosing the right type is critical. Engaging with industry experts or consulting valve manufacturers can ensure that the selection is tailored to the specific demands of one's operational environment. The expert knowledge in this domain emphasizes that without the strategic integration of these valves, systems are susceptible to inefficiencies and failures that could have been otherwise avoided. It is this understanding that showcases the authority and trustworthiness of advice regarding the implementation of DI air valves. In summary, the DI air valve is more than just a product; it is an investment in reliability and efficiency across multiple industrial landscapes. With its expertise-enriched design and authoritative presence across different sectors, it promises to be a trusted ally for any business aspiring to optimize its operational processes. Trust in the DI air valve is a testament to intelligent engineering, and its increasing deployment speaks volumes of its indispensable role in modern industry.

Share

Prev:

Next: