Desemba . 13, 2024 00:03 Back to list

cast steel check valve

Understanding Cast Steel Check Valves Function, Advantages, and Applications

Check valves, especially those made from cast steel, play a crucial role in various fluid systems by ensuring that the flow of liquid does not reverse. Designed to allow fluid to flow in one direction while preventing backflow, cast steel check valves are integral components in many industrial processes, from water supply systems to oil and gas pipelines. This article explores the features, advantages, and applications of cast steel check valves.

What is a Cast Steel Check Valve?

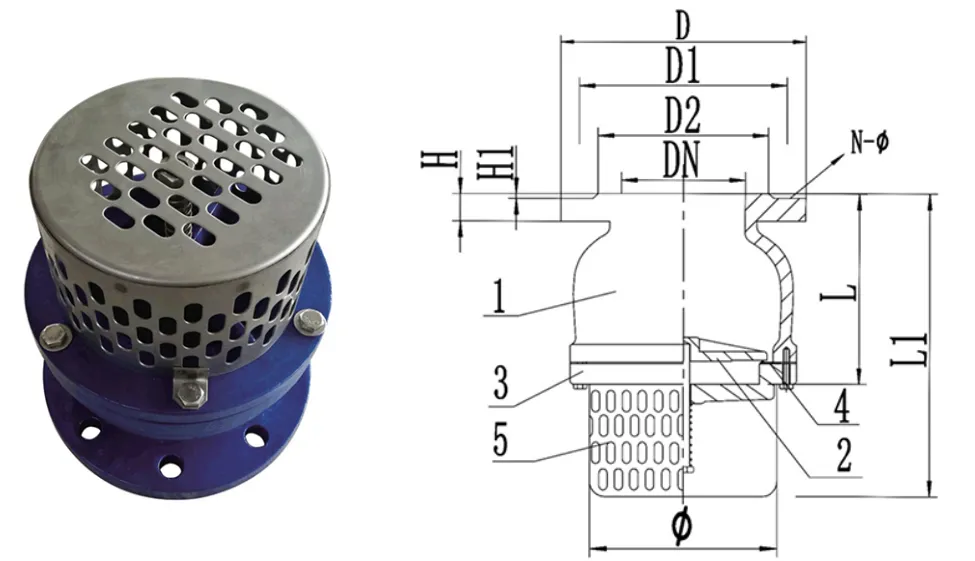

A cast steel check valve is a one-way valve that is manufactured using cast steel, a material known for its robustness and ability to withstand high pressure and temperature. These valves are typically installed in pipelines to control fluid flow in a specific direction, thereby preventing potential damage caused by backflow. The mechanism of operation relies on the pressure differential between the inlet and outlet; when the pressure at the inlet is greater than that at the outlet, the valve opens. Conversely, when backpressure occurs, the valve closes, preventing any reverse flow.

Key Features

1. Material Durability Cast steel is renowned for its strength and resilience. It can effectively handle high-pressure environments, making it suitable for heavy-duty applications. Additionally, cast steel provides excellent resistance to thermal stress, corrosion, and wear, ensuring longevity in various operating conditions.

2. Design Versatility Cast steel check valves come in various designs, including swing, lift, and diaphragm types. This flexibility allows engineers to select the most appropriate valve based on the specific requirements of their systems, whether it be for liquid, gas, or steam.

3. Size Range These valves can be manufactured in a wide range of sizes, accommodating various pipeline dimensions. This versatility makes them suitable for both small-scale applications and large industrial systems.

4. Maintenance and Serviceability Cast steel check valves are designed for easy maintenance. They typically require minimal servicing, and their robust construction means that they can withstand years of operation without significant wear.

Advantages of Cast Steel Check Valves

1. Reliability The primary advantage of using cast steel check valves is their reliability. Their one-way functionality ensures that the integrity of the system is maintained, preventing potential system failures caused by backflow.

cast steel check valve

2. Cost-Effective While the initial investment may be higher due to the premium material, the long lifespan and low maintenance costs associated with cast steel check valves make them a cost-effective choice in the long term.

3. Operational Efficiency By preventing backflow, these valves help maintain the efficiency of fluid transport systems. This can lead to energy savings and reduced operational costs as the system does not have to work against backpressure.

4. Safety In systems that transport hazardous fluids, such as chemicals and gases, preventing backflow is crucial for safety. Cast steel check valves enhance the safety profile of such systems by ensuring that the fluid flows in a controlled manner.

Applications

Cast steel check valves find their utility across a wide range of industries

1. Water and Wastewater Treatment In these systems, they help control flow in pumping stations and treatment plants to ensure that water moves through the system effectively.

2. Oil and Gas Industry These valves are critical in preventing backflow in pipelines, particularly in offshore and onshore drilling operations where fluid pressure changes are common.

3. Power Generation In power plants, cast steel check valves are used in steam and cooling water systems to ensure proper flow and heat transfer.

4. Chemical Processing Due to their resistance to corrosive materials, cast steel check valves are ideal for chemical processing applications where they manage the flow of various chemicals safely.

Conclusion

Cast steel check valves are vital components in many fluid systems, providing reliability, durability, and safety. Their unique features, including material strength, design flexibility, and ease of maintenance, make them an excellent choice for various applications across multiple industries. As technology advances, the development of even more efficient and durable check valves will further enhance their effectiveness in safeguarding systems from the risks of backflow, ensuring efficient operations well into the future.

Share