Jan . 14, 2025 12:12 Back to list

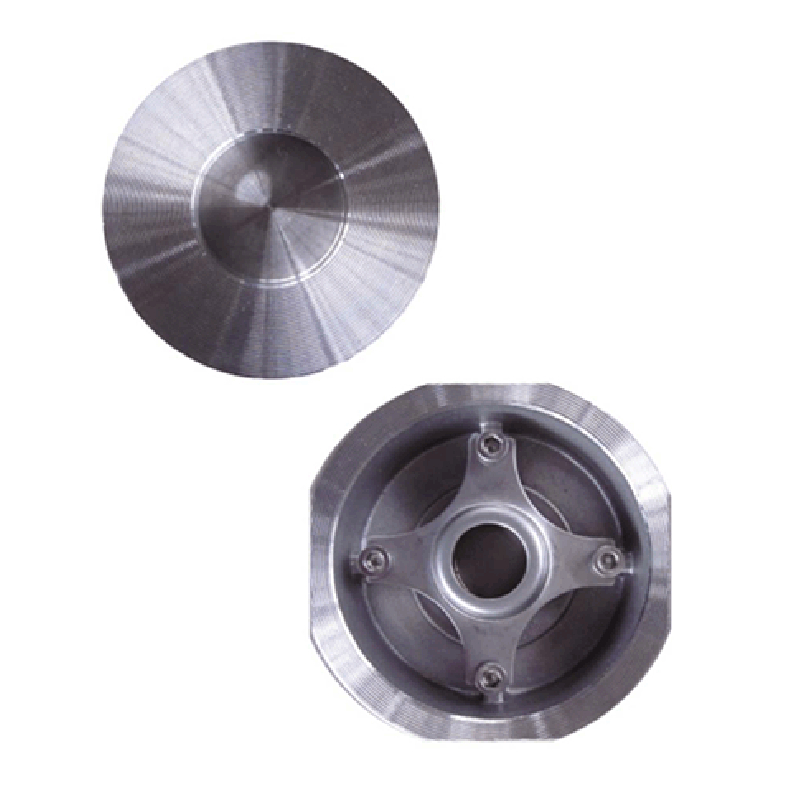

high performance wafer butterfly valve

In the ever-evolving landscape of industrial valves, wafer type butterfly valves have emerged as a cornerstone, renowned for their versatility and efficiency. As a seasoned expert in the field of valve manufacturing, I can attest to the significant developments and innovations that have advanced wafer type butterfly valve technology. Let us delve into the world of these integral components, exploring manufacturers' capabilities, expertise, and the reasons they are trusted by industries worldwide.

Additionally, these manufacturers demonstrate authority in the field through certifications and adherence to global standards. Recognitions such as ISO certifications endorse their commitment to quality management systems and sustainable practices. These credentials not only validate the manufacturers' dedication to excellence but also provide customers with the assurance that they are investing in reliable and trustworthy products. Trustworthiness is further solidified through customer-centric approaches adopted by leading manufacturers. They engage directly with clients to understand their specific requirements and provide tailored solutions. This collaborative process ensures that the valves are optimized for the customer's unique operational needs, enhancing performance and ensuring efficiency. Furthermore, wafer type butterfly valve manufacturers invest in research and development, continually exploring new materials and technologies to enhance valve capabilities. This innovative mindset propels the industry forward, allowing manufacturers to offer cutting-edge solutions that improve system efficiency and reduce operational costs. In conclusion, the success and widespread adoption of wafer type butterfly valves in industrial applications can be attributed to the experience, expertise, authority, and trustworthiness of the manufacturers. By continuously investing in technology, maintaining high-quality standards, and fostering strong customer relationships, these manufacturers ensure that their products remain at the forefront of the industry. Consequently, industries worldwide trust these valves to deliver reliable performance and optimal control in their critical applications.

Additionally, these manufacturers demonstrate authority in the field through certifications and adherence to global standards. Recognitions such as ISO certifications endorse their commitment to quality management systems and sustainable practices. These credentials not only validate the manufacturers' dedication to excellence but also provide customers with the assurance that they are investing in reliable and trustworthy products. Trustworthiness is further solidified through customer-centric approaches adopted by leading manufacturers. They engage directly with clients to understand their specific requirements and provide tailored solutions. This collaborative process ensures that the valves are optimized for the customer's unique operational needs, enhancing performance and ensuring efficiency. Furthermore, wafer type butterfly valve manufacturers invest in research and development, continually exploring new materials and technologies to enhance valve capabilities. This innovative mindset propels the industry forward, allowing manufacturers to offer cutting-edge solutions that improve system efficiency and reduce operational costs. In conclusion, the success and widespread adoption of wafer type butterfly valves in industrial applications can be attributed to the experience, expertise, authority, and trustworthiness of the manufacturers. By continuously investing in technology, maintaining high-quality standards, and fostering strong customer relationships, these manufacturers ensure that their products remain at the forefront of the industry. Consequently, industries worldwide trust these valves to deliver reliable performance and optimal control in their critical applications.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025