Jan . 26, 2025 03:10 Back to list

Dismantling Joint

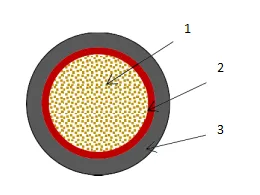

Expansion rubber joints have become an indispensable component in modern industrial applications, providing a viable solution to several operational challenges including vibration isolation, thermal expansion, and noise reduction. Crafted from flexible materials, these joints facilitate the seamless connection of rigid systems such as pipelines, offering multiple advantages including enhanced durability and system longevity. For businesses aiming to optimize the efficacy of their machinery, understanding the nuanced benefits and applications of expansion rubber joints is imperative.

Moreover, the installation of expansion rubber joints provides substantial noise reduction benefits. In systems where fluid pulsation or turbulence is prevalent, these joints act as buffers, diminishing the transmission of noise along the pipes. This noise suppression is particularly valuable in residential and commercial buildings where acoustic comfort is a priority. Trustworthiness in the performance of expansion rubber joints is achieved through ongoing research and development efforts by industry leaders. Investments in innovation empower engineers to develop joints with advanced features such as higher pressure ratings and enhanced movement capabilities, ensuring that these joints remain reliable under the most extreme operational conditions. Testimonials from industry professionals underscore the reliability and efficiency of expansion rubber joints. Engineers have attested to noticeable reductions in maintenance issues and improvements in system performance after incorporating these joints into their designs. The longevity and resilience of these components lead to increased confidence in their deployment across various operational sectors. In conclusion, expansion rubber joints symbolize an essential element in the toolkit of modern infrastructure management. Their ability to mitigate mechanical stresses, isolate vibrations, and accommodate thermal expansion make them a vital asset to numerous industries. As technologies advance and operational demands become more complex, the reliance on these flexible connectors will undoubtedly continue to grow, solidifying their place as crucial components in the landscape of industrial engineering.

Moreover, the installation of expansion rubber joints provides substantial noise reduction benefits. In systems where fluid pulsation or turbulence is prevalent, these joints act as buffers, diminishing the transmission of noise along the pipes. This noise suppression is particularly valuable in residential and commercial buildings where acoustic comfort is a priority. Trustworthiness in the performance of expansion rubber joints is achieved through ongoing research and development efforts by industry leaders. Investments in innovation empower engineers to develop joints with advanced features such as higher pressure ratings and enhanced movement capabilities, ensuring that these joints remain reliable under the most extreme operational conditions. Testimonials from industry professionals underscore the reliability and efficiency of expansion rubber joints. Engineers have attested to noticeable reductions in maintenance issues and improvements in system performance after incorporating these joints into their designs. The longevity and resilience of these components lead to increased confidence in their deployment across various operational sectors. In conclusion, expansion rubber joints symbolize an essential element in the toolkit of modern infrastructure management. Their ability to mitigate mechanical stresses, isolate vibrations, and accommodate thermal expansion make them a vital asset to numerous industries. As technologies advance and operational demands become more complex, the reliance on these flexible connectors will undoubtedly continue to grow, solidifying their place as crucial components in the landscape of industrial engineering.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025