Jan . 22, 2025 03:27 Back to list

2 core cable manufacturer

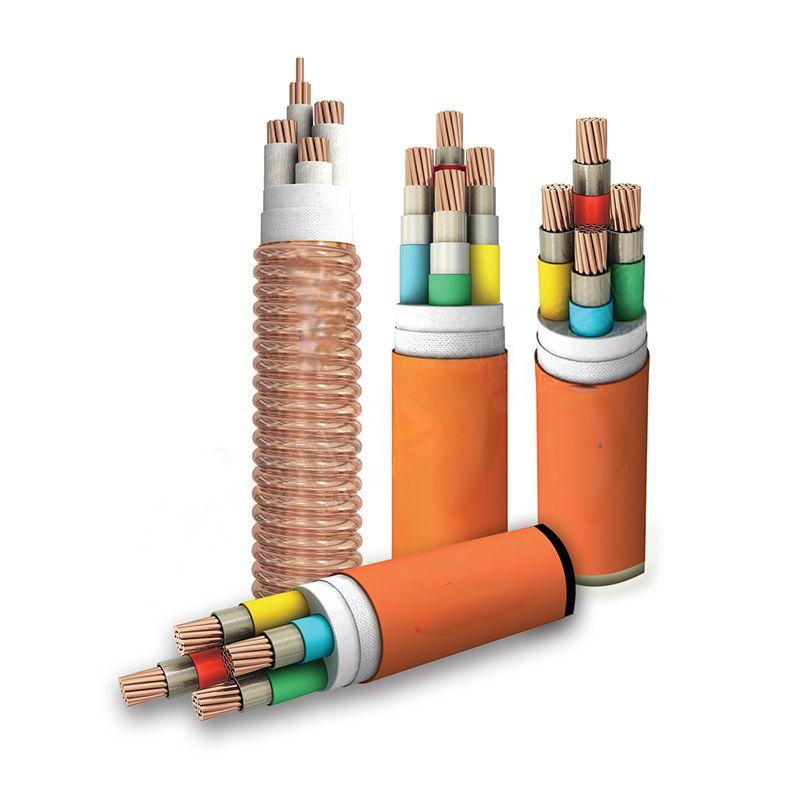

When it comes to selecting the right electrical components for both residential and commercial projects, the 3 core wire cable stands out as an indispensable choice. With its versatile nature and wide range of applications, it is crucial for professionals and do-it-yourself enthusiasts to understand its benefits, technical specifications, and best practices for installation.

Trustworthiness is further enhanced by the rigorous testing these cables undergo before reaching the market. High-quality 3 core wire cables often come with certifications from third-party agencies, ensuring they meet stringent safety and performance criteria. This factor is crucial for maintaining the integrity of electrical installations and preventing future failures or hazards. Practical experience highlights that correct installation is key to maximizing the benefits of a 3 core wire cable. It is recommended to carefully consider the cable's bend radius during installation to prevent internal damage or stresses that could compromise its integrity. Moreover, using appropriate connectors and terminologies is vital to ensure a secure and stable connection. Troubleshooting common issues with 3 core wire cables involves regular inspection and testing for signs of wear, such as fraying or insulation cracking. Proper maintenance not only extends the cable's lifespan but also ensures continuous operation without unexpected disruptions. Incorporating a 3 core wire cable into any project leverages the balance of safety, efficiency, and flexibility. Professionals and homeowners alike continue to trust this type of cable for its established performance and wide scope of application. Adherence to best practices, combined with a thorough understanding of its attributes, empowers individuals to make informed decisions, tailoring their electrical systems to meet present and future demands effectively.

Trustworthiness is further enhanced by the rigorous testing these cables undergo before reaching the market. High-quality 3 core wire cables often come with certifications from third-party agencies, ensuring they meet stringent safety and performance criteria. This factor is crucial for maintaining the integrity of electrical installations and preventing future failures or hazards. Practical experience highlights that correct installation is key to maximizing the benefits of a 3 core wire cable. It is recommended to carefully consider the cable's bend radius during installation to prevent internal damage or stresses that could compromise its integrity. Moreover, using appropriate connectors and terminologies is vital to ensure a secure and stable connection. Troubleshooting common issues with 3 core wire cables involves regular inspection and testing for signs of wear, such as fraying or insulation cracking. Proper maintenance not only extends the cable's lifespan but also ensures continuous operation without unexpected disruptions. Incorporating a 3 core wire cable into any project leverages the balance of safety, efficiency, and flexibility. Professionals and homeowners alike continue to trust this type of cable for its established performance and wide scope of application. Adherence to best practices, combined with a thorough understanding of its attributes, empowers individuals to make informed decisions, tailoring their electrical systems to meet present and future demands effectively.

Share

Prev:

Next: