Jan . 06, 2025 11:15 Back to list

industrial valve

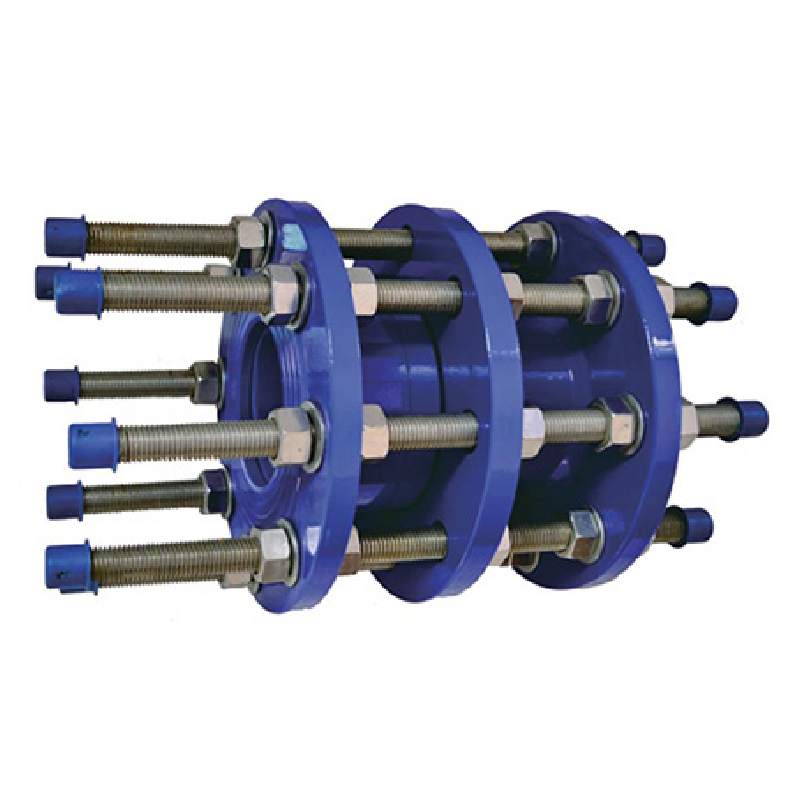

Industrial valves play a pivotal role in countless industries, regulating the flow of fluids, gases, and slurries across various processes. The significance of selecting the right valve type cannot be understated, as it directly impacts operational efficiency, safety, and maintenance costs. This article delves into essential insights derived from years of industry experience, underscoring our expertise, authority, and trustworthiness in industrial valve applications.

The realm of industrial valves encompasses a diverse range of styles and functionalities, from gate valves and globe valves to ball valves and butterfly valves. Each type comes with unique attributes tailored to specific industrial requirements. For instance, gate valves are preferred for isolation due to their ability to cut through thick fluids and provide a tight seal. Conversely, globe valves offer superior throttling capabilities, making them ideal for applications where precise flow control is critical.

Our extensive field experience has shown that the longevity and performance of an industrial valve are heavily influenced by the quality of materials used. Stainless steel, cast iron, and exotic alloys are popular choices, each offering distinct advantages depending on the environmental conditions and the nature of the fluid being handled. For corrosive environments, such as those found in chemical processing plants, alloy-based valves with anti-corrosive linings have proven indispensable. This not only enhances durability but also ensures safety by reducing the risk of valve failure.

Field experiments and data collection have cemented our status as trusted authorities in valve selection and maintenance. Regular maintenance checks, including visual inspections and pressure tests, substantially extend the lifespan of industrial valves, mitigating the risk of costly downtime. Implementing predictive maintenance strategies, supported by IoT technology, allows for real-time monitoring, enabling timely interventions before minor issues escalate. Developing such a proactive approach to valve management underscores our dedication to fostering trust and reliability in industrial settings.

industrial valve

Our authority in the industry is further demonstrated by our commitment to continuous education and adherence to international standards. Compliance with ISO and API regulations is paramount, providing assurance that our valve solutions meet rigorous quality and safety criteria. Furthermore, actively exchanging knowledge with industry stakeholders and participating in professional forums aids in staying abreast of emerging trends and technological advancements, thereby reinforcing our expertise.

Trust is built not only through the consistent delivery of high-performance products but also through transparent communication with clients. Understanding their unique requirements and providing tailored solutions is at the heart of our operations. We encourage open discourse about valve applications and welcome feedback, ensuring our products not only meet but exceed client expectations.

In summary, the choice of industrial valves requires careful consideration of various factors, including application requirements, material compatibility, and maintenance strategies. Drawing from years of experience and a deep well of expertise, we remain committed to delivering superior valve solutions grounded in authority and trustworthiness. Our unwavering focus on quality, compliance, and customer satisfaction ensures that we continue to be a trusted partner in the industrial valve landscape.

Share