Feb . 11, 2025 14:43 Back to list

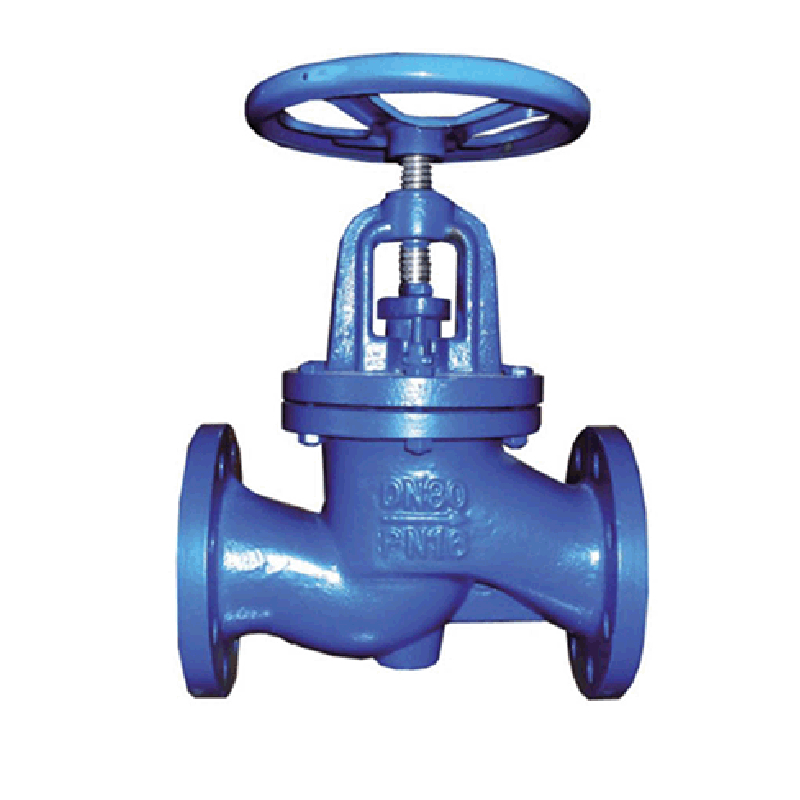

lift check valve

In the realm of industrial machinery and pipeline systems, the lift check valve emerges as an unsung hero, consistently ensuring efficient flow directionality and protection against backflow. This vital component finds its utility transcending various industries, driven by both its structural integrity and functional resilience.

Professional authorities in valve manufacturing continually advocate for the lift check valve by emphasizing its simplicity and effectiveness. Compared to more complex mechanical systems, the lift check valve operates with minimal moving parts, reducing the chances of mechanical failure and maintenance overhead. This directness not only guarantees reliability but also simplifies troubleshooting, reinforcing the valve's authoritative position in fluid dynamics management. The trustworthiness of a lift check valve is paramount and rooted in rigorous industry standards and certifications. Manufacturers often subject these valves to exhaustive testing protocols to comply with international standards such as ANSI, ASME, and API certifications. These certifications are testimonials to the valve’s performance under extreme conditions, fostering confidence among engineers and maintenance personnel. A consistent performance record and compliance with safety standards build trust, reassuring stakeholders of the valve’s reliability and the safety it imparts to an entire fluid system. Choosing the right lift check valve involves considering several crucial factors. System pressure, flow rates, and temperature variations are principal factors influencing the selection. Engineers rely on performance data from extensive testing scenarios to match the right valve to the system's specifications. Additionally, anticipated maintenance schedules and ease of access are logistical considerations that guide the final selection. In conclusion, the lift check valve serves as more than just a regulatory component; it embodies engineering excellence, empirical reliability, and strategic importance. Its simplicity belies the critical role it plays in safeguarding complex fluid systems against potentially catastrophic failures. As industries strive for optimized performance and safety, the lift check valve continues to be a cornerstone of pipeline integrity, showcasing an impressive balance of experience-backed efficiency and professionally endorsed authority.

Professional authorities in valve manufacturing continually advocate for the lift check valve by emphasizing its simplicity and effectiveness. Compared to more complex mechanical systems, the lift check valve operates with minimal moving parts, reducing the chances of mechanical failure and maintenance overhead. This directness not only guarantees reliability but also simplifies troubleshooting, reinforcing the valve's authoritative position in fluid dynamics management. The trustworthiness of a lift check valve is paramount and rooted in rigorous industry standards and certifications. Manufacturers often subject these valves to exhaustive testing protocols to comply with international standards such as ANSI, ASME, and API certifications. These certifications are testimonials to the valve’s performance under extreme conditions, fostering confidence among engineers and maintenance personnel. A consistent performance record and compliance with safety standards build trust, reassuring stakeholders of the valve’s reliability and the safety it imparts to an entire fluid system. Choosing the right lift check valve involves considering several crucial factors. System pressure, flow rates, and temperature variations are principal factors influencing the selection. Engineers rely on performance data from extensive testing scenarios to match the right valve to the system's specifications. Additionally, anticipated maintenance schedules and ease of access are logistical considerations that guide the final selection. In conclusion, the lift check valve serves as more than just a regulatory component; it embodies engineering excellence, empirical reliability, and strategic importance. Its simplicity belies the critical role it plays in safeguarding complex fluid systems against potentially catastrophic failures. As industries strive for optimized performance and safety, the lift check valve continues to be a cornerstone of pipeline integrity, showcasing an impressive balance of experience-backed efficiency and professionally endorsed authority.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025