Jan . 13, 2025 15:10 Back to list

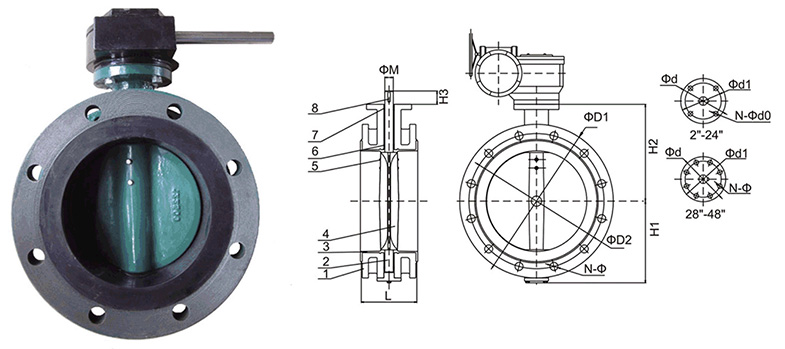

double eccentric flange butterfly valve

Navigating the complex world of industrial valves can be daunting, especially when seeking a solution that offers both efficiency and reliability. The double eccentric flange butterfly valve stands out in this sphere, providing robust and dependable service in various applications. As companies strive to optimize their fluid handling systems, understanding the nuances of this valve type can lead to enhanced operational success.

Moreover, the ease of installation and maintenance of the double eccentric flange butterfly valve significantly contributes to its popularity among engineers and maintenance professionals. The straightforward design allows for quick installation and minimal downtime during servicing, which conveys cost-effectiveness over the valve's operational lifespan. This efficiency is further bolstered by the valve's capability to self-clean, reducing clogging and facilitating smoother operations. Establishing trust in such a critical component hinges on the expertise and authority of the manufacturer. Leading suppliers invest in rigorous quality control measures, ensuring each valve meets stringent industry standards before reaching the market. Certifications such as ISO 9001 and API conformances are vital hallmarks of a reputable valve provider, assuring end-users of the valve's performance reliability and safety. In conclusion, the double eccentric flange butterfly valve is more than just a component in a piping system; it is a strategic choice for optimizing flow control while minimizing maintenance and enhancing system integrity. By understanding its benefits and evaluating its suitability for specific applications, engineers and operators can make informed decisions that contribute to efficient plant operations. A commitment to quality and informed choice ensures that these valves continue to be a crucial element in advancing industrial fluid dynamics.

Moreover, the ease of installation and maintenance of the double eccentric flange butterfly valve significantly contributes to its popularity among engineers and maintenance professionals. The straightforward design allows for quick installation and minimal downtime during servicing, which conveys cost-effectiveness over the valve's operational lifespan. This efficiency is further bolstered by the valve's capability to self-clean, reducing clogging and facilitating smoother operations. Establishing trust in such a critical component hinges on the expertise and authority of the manufacturer. Leading suppliers invest in rigorous quality control measures, ensuring each valve meets stringent industry standards before reaching the market. Certifications such as ISO 9001 and API conformances are vital hallmarks of a reputable valve provider, assuring end-users of the valve's performance reliability and safety. In conclusion, the double eccentric flange butterfly valve is more than just a component in a piping system; it is a strategic choice for optimizing flow control while minimizing maintenance and enhancing system integrity. By understanding its benefits and evaluating its suitability for specific applications, engineers and operators can make informed decisions that contribute to efficient plant operations. A commitment to quality and informed choice ensures that these valves continue to be a crucial element in advancing industrial fluid dynamics.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025