Feb . 12, 2025 13:04 Back to list

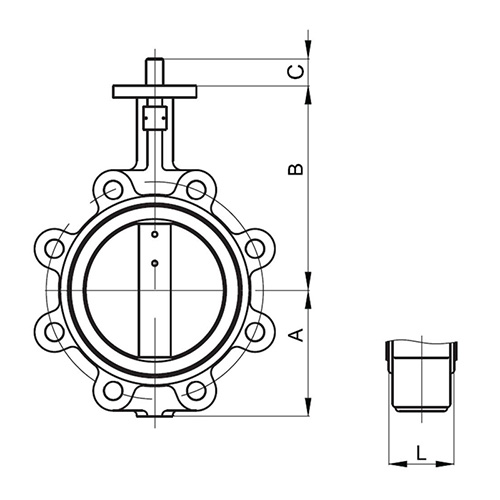

Wafer Type Butterfly Valve

When it comes to the intricate world of plumbing systems, a cast iron valve stands out not just for its durability but for its unparalleled performance under various operational conditions. Cast iron valves are known for their robust construction, resistance to wear, and high-pressure tolerance, making them an indispensable component in both residential and industrial applications.

Furthermore, the expertise in selecting the right valve for a specific application cannot be understated. Factors such as the type of fluid being handled, the operating temperature, and system pressure all play a vital role in determining the appropriate valve choice. A certified professional should always be consulted to ensure that the valve specifications align with the operational demands. The decision to incorporate cast iron valves in any system speaks volumes about prioritizing reliability and performance. Though initial investment might be higher than alternatives like plastic or even some metal valves, the long-term savings in maintenance and replacement costs make them the smarter choice for serious projects. To build a more authoritative understanding, consider evaluating case studies where cast iron valves have been used successfully over decades in infrastructure projects worldwide. These real-world applications not only testify to their durability and efficiency but also build a trustworthy reputation among engineers and system designers. In conclusion, when considering valves for high-demand environments, the cast iron valve remains a top-tier choice. Its blend of strength, longevity, and versatile application ensures peace of mind that few other materials can match. For those seeking not just a component but a cornerstone in their fluid control systems, turning to cast iron valves is a decision grounded in experience, expertise, authority, and trustworthiness.

Furthermore, the expertise in selecting the right valve for a specific application cannot be understated. Factors such as the type of fluid being handled, the operating temperature, and system pressure all play a vital role in determining the appropriate valve choice. A certified professional should always be consulted to ensure that the valve specifications align with the operational demands. The decision to incorporate cast iron valves in any system speaks volumes about prioritizing reliability and performance. Though initial investment might be higher than alternatives like plastic or even some metal valves, the long-term savings in maintenance and replacement costs make them the smarter choice for serious projects. To build a more authoritative understanding, consider evaluating case studies where cast iron valves have been used successfully over decades in infrastructure projects worldwide. These real-world applications not only testify to their durability and efficiency but also build a trustworthy reputation among engineers and system designers. In conclusion, when considering valves for high-demand environments, the cast iron valve remains a top-tier choice. Its blend of strength, longevity, and versatile application ensures peace of mind that few other materials can match. For those seeking not just a component but a cornerstone in their fluid control systems, turning to cast iron valves is a decision grounded in experience, expertise, authority, and trustworthiness.

Share