Aug . 28, 2024 10:49 Back to list

High-Quality Rubber Joints - Durable and Reliable Solutions

The Importance and Applications of Rubber Joints

Rubber joints, also known as flexible joints, are essential components in various mechanical systems. They primarily serve as connectors between different piping or ductwork systems, allowing for flexibility and movement while minimizing vibrations and noise. The use of rubber joints is widespread across diverse industries, including construction, automotive, and manufacturing, owing to their superior cushioning properties and resistance to environmental factors.

One of the main advantages of rubber joints is their ability to absorb shocks and vibrations

. In industrial settings, machinery can generate significant amounts of vibration, which, if not managed, may lead to wear and tear, damage to equipment, or even safety hazards. By incorporating rubber joints, industries can mitigate these risks, ensuring smoother operations and prolonged equipment lifespan. This is particularly crucial in sectors where precision and reliability are paramount, such as aerospace and automotive manufacturing.Rubber joints are also beneficial in managing thermal expansion and contraction in piping systems. As temperatures fluctuate, materials tend to expand or contract. Rubber joints facilitate this movement, preventing stress on the pipes and potential leaks. This property is particularly valuable in environments that experience extreme temperature changes, ensuring the integrity and efficiency of the system operates without interruption.

rubber joint

In addition to their functional advantages, rubber joints can also contribute to noise reduction in various applications. The flexibility of rubber material helps dampen sound waves that can travel through rigid piping systems, making environments quieter. This feature is particularly advantageous in residential areas or workplaces where excessive noise can lead to discomfort or decreased productivity.

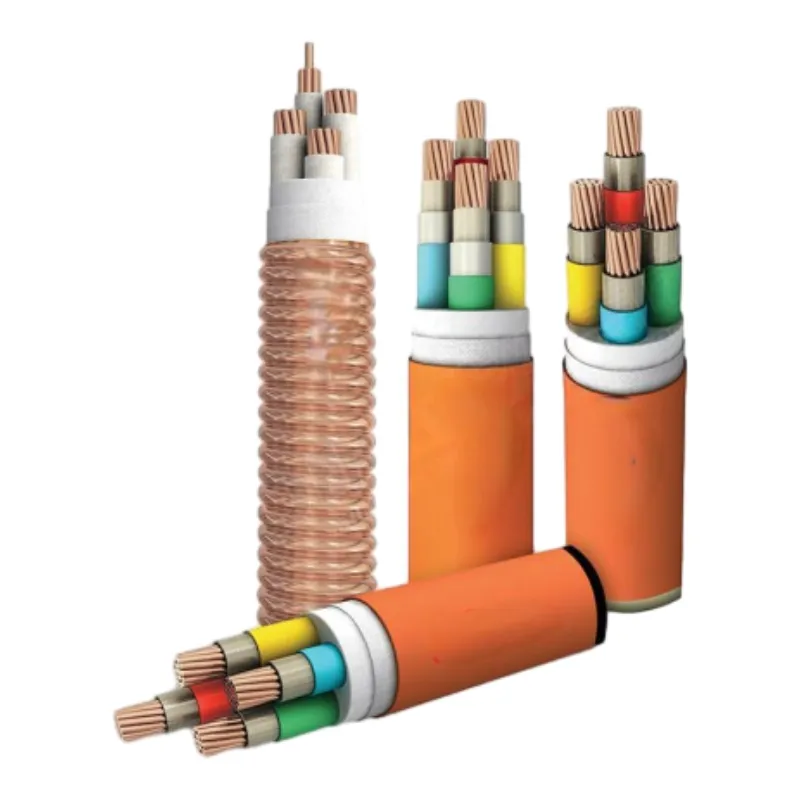

Moreover, rubber joints are available in various shapes, sizes, and materials, making them customizable for specific applications. They can be manufactured from a variety of rubber compounds that are resistant to oils, chemicals, and weather, ensuring they perform well in challenging environments. This versatility allows engineers and designers to select the most suitable rubber joint for their specific needs, enhancing overall system performance.

In conclusion, rubber joints play a vital role in modern engineering and infrastructure. Their ability to absorb vibrations, accommodate thermal expansion, and reduce noise makes them indispensable components in various systems. As industries continue to advance, the demand for reliable and efficient rubber joints is expected to grow. Investing in high-quality rubber joints not only enhances system performance but also contributes to increased safety and longevity of equipment, making them a wise choice for any mechanical application.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025