Aug . 28, 2024 10:50 Back to list

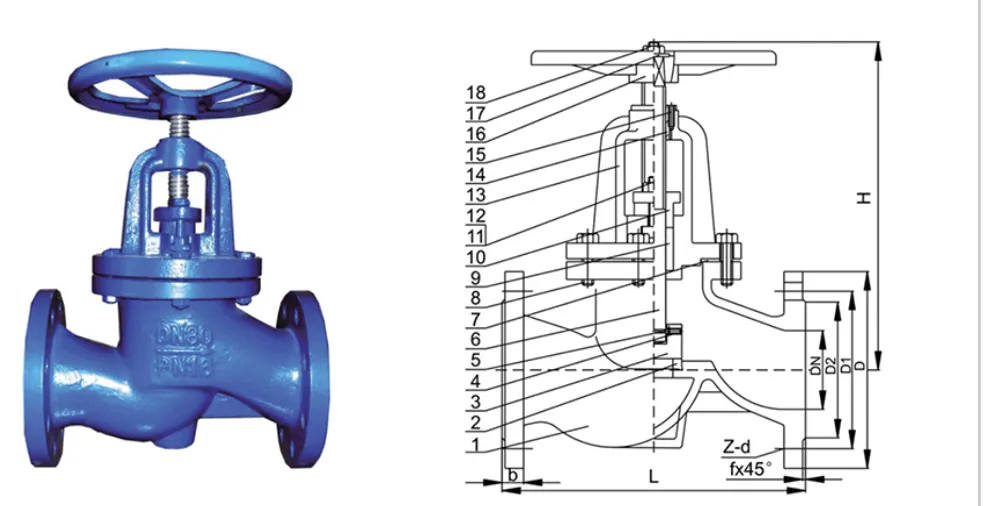

High-Quality Cast Iron Metal Seat Gate Valve - Durable and Reliable Solutions

The Versatility and Benefits of Cast Iron Metal Seat Gate Valves

Gate valves are vital components in a wide array of fluid systems, acting as a shutoff device to control the flow of liquids and gases. Among the various types of gate valves available in the market, cast iron metal seat gate valves have gained prominence due to their unique properties and advantages. This article delves into the features, applications, and benefits of cast iron metal seat gate valves.

Cast iron is a group of iron-carbon alloys known for its excellent castability, durability, and strength. In the context of gate valves, cast iron provides a robust structure that can withstand high pressure and temperature conditions. The metal seat design enhances the valve's performance by providing a smooth surface for sealing, which is crucial in preventing leakage when the valve is closed. Unlike soft seat valves, metal seat gate valves have a longer lifespan in demanding environments where abrasives and high temperatures are present.

One of the key advantages of cast iron metal seat gate valves is their resistance to corrosion

. While cast iron may corrode under certain conditions, the metal seat ensures that the sealing surface remains intact, enhancing the valve's overall service life. This makes cast iron valves particularly suitable for applications involving water, oil, and gas, where exposure to harsh environments can lead to significant wear and degradation.cast iron metal seat gate valve

Cast iron metal seat gate valves are often employed in various industries, including water treatment plants, oil and gas pipelines, and power generation facilities. Their ability to handle high flow rates makes them ideal for systems requiring minimal pressure loss. In water distribution networks, for example, these valves effectively manage the flow of water, ensuring that systems operate smoothly and efficiently.

Furthermore, the design simplicity of gate valves contributes to their easy maintenance. Technicians can easily access the valve internals, allowing for quick inspections, repairs, or replacements when necessary. This low maintenance requirement is a boon for industries aiming to minimize operational downtime and extend the lifespan of their equipment.

Another significant benefit of these valves is their cost-effectiveness. The durability and longevity of cast iron metal seat gate valves mean that organizations can save money over time by reducing the need for frequent replacements. Moreover, their efficient performance contributes to better resource management, which is critical for industries seeking sustainable practices.

In conclusion, cast iron metal seat gate valves are an exceptional choice for various industrial applications due to their durability, corrosion resistance, and ease of maintenance. Their ability to withstand challenging conditions while providing a reliable seal makes them invaluable in managing the flow of fluids. As industries evolve and seek more reliable and cost-effective solutions, cast iron metal seat gate valves will undoubtedly remain an essential component in fluid control systems. By choosing these valves, organizations can ensure optimal performance, reduced operational costs, and a longer service life, ultimately contributing to overall efficiency and productivity.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025