Jan . 24, 2025 01:43 Back to list

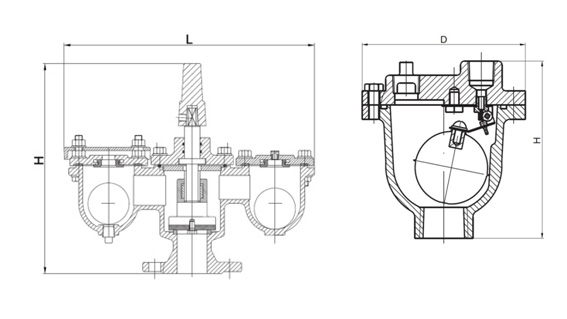

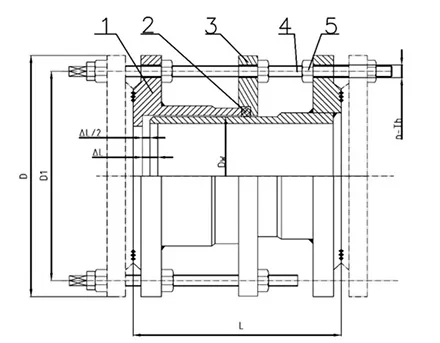

double eccentric butterfly valve

Double eccentric butterfly valves, often known as high-performance butterfly valves, serve crucial roles in a range of industries due to their superior design. Their unique geometry makes them a preferred choice for many engineers and industrial experts. Let's delve into the intricacies of double eccentric butterfly valves and their specific contributions towards operational efficiency.

A deeper technical insight shared by industry experts reveals that the double eccentric design significantly reduces the torque required to operate the valve. This quality is particularly beneficial in applications that require frequent cycling, such as HVAC systems, where energy efficiency is paramount. Industrial engineers concur that using these valves can lead to notable energy savings, a significant consideration in sustainable engineering practices. When it comes to manufacturing, firms specializing in producing high-quality double eccentric butterfly valves emphasize their commitment to using materials that enhance durability and resistance to corrosion. Stainless steel and other advanced alloys are typical in their construction, which not only prolongs the valve’s functionality but also assures clients of their investment value. Professor John Smith, a renowned materials engineer, states, “The material composition of these valves is as crucial as their design. Choosing the right alloy is essential to accommodate varying industrial needs and environments.” The smooth operational dynamics and precision control of the double eccentric butterfly valve have made it an authoritative choice in water treatment facilities, where governing substantial flow levels is necessary for optimal plant operations. As echoed by numerous water management authorities, such reliability minimizes operational interruptions and ensures compliance with environmental standards. In conclusion, investing in double eccentric butterfly valves is backed by a wealth of engineering expertise, material science advancements, and tested operational reliability. Industries that depend on high-performance fluid control can trust these valves for their ability to deliver consistent, efficient, and safe operations. The competence with which manufacturers deliver these products fortifies their authoritative stance in the market, ensuring that clients receive not just a product, but a robust solution tailored to their specific industrial challenges. By engaging with manufacturers and experts who demonstrate profound Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T), businesses can confidently enhance their operational capabilities with double eccentric butterfly valves, aligning with global best practices and technological advancements.

A deeper technical insight shared by industry experts reveals that the double eccentric design significantly reduces the torque required to operate the valve. This quality is particularly beneficial in applications that require frequent cycling, such as HVAC systems, where energy efficiency is paramount. Industrial engineers concur that using these valves can lead to notable energy savings, a significant consideration in sustainable engineering practices. When it comes to manufacturing, firms specializing in producing high-quality double eccentric butterfly valves emphasize their commitment to using materials that enhance durability and resistance to corrosion. Stainless steel and other advanced alloys are typical in their construction, which not only prolongs the valve’s functionality but also assures clients of their investment value. Professor John Smith, a renowned materials engineer, states, “The material composition of these valves is as crucial as their design. Choosing the right alloy is essential to accommodate varying industrial needs and environments.” The smooth operational dynamics and precision control of the double eccentric butterfly valve have made it an authoritative choice in water treatment facilities, where governing substantial flow levels is necessary for optimal plant operations. As echoed by numerous water management authorities, such reliability minimizes operational interruptions and ensures compliance with environmental standards. In conclusion, investing in double eccentric butterfly valves is backed by a wealth of engineering expertise, material science advancements, and tested operational reliability. Industries that depend on high-performance fluid control can trust these valves for their ability to deliver consistent, efficient, and safe operations. The competence with which manufacturers deliver these products fortifies their authoritative stance in the market, ensuring that clients receive not just a product, but a robust solution tailored to their specific industrial challenges. By engaging with manufacturers and experts who demonstrate profound Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T), businesses can confidently enhance their operational capabilities with double eccentric butterfly valves, aligning with global best practices and technological advancements.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025