Aug . 28, 2024 11:56 Back to list

Check Valve with Counterweight - Efficient Flow Control Solutions

Understanding Check Valves with Counterweights Functionality and Benefits

Check valves are essential components in various fluid systems, ensuring that liquids or gases flow in one direction while preventing backflow

. Among the numerous types of check valves available, the check valve with counterweight stands out due to its unique operational mechanism and advantages in specific applications.A check valve with counterweights is designed to enhance the traditional check valve's performance. The counterweight, usually a hinged component, is used to assist in the opening and closing of the valve. This system allows for more controlled movement, which is crucial in environments where pressure fluctuations occur frequently. As fluid begins to flow in the intended direction, the weight helps in overcoming the inertia of the valve disc, facilitating a smoother opening process. Conversely, when the fluid attempts to flow back, the counterweight helps in closing the valve promptly, preventing any reverse flow.

One of the critical benefits of incorporating a counterweight is its ability to reduce the potential for water hammer—a phenomenon that occurs when a fluid in motion is suddenly forced to stop or change direction. Water hammer can cause significant damage to piping systems due to the shockwave created by the abrupt pressure change. By employing a check valve with a counterweight, the valve can respond more gently to changes in flow, minimizing shock and preserving the integrity of the system.

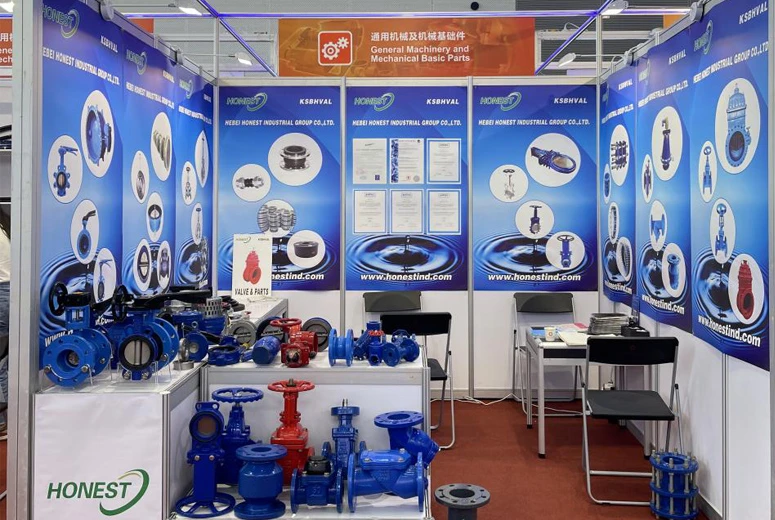

check valve with counterweight

Another advantage is energy efficiency. Traditional check valves often require external power sources for actuation in some applications. The counterweight mechanism operates using the natural force of gravity, which can lead to a cost-effective solution for various industries. This energy-saving aspect becomes particularly beneficial for large-scale operations, such as in water treatment plants and industrial processes, where efficiency translates to substantial cost savings.

Furthermore, check valves with counterweights are versatile and can be adapted for various applications, from municipal water systems to chemical processing facilities. Their design can accommodate different sizes and pressure ratings, making them suitable for diverse environments. Maintenance is straightforward due to fewer moving parts compared to other valve types, ensuring longevity and reducing downtime.

In summary, check valves with counterweights present a reliable solution for managing fluid flow in various industries. Their ability to prevent backflow while effectively mitigating the risks associated with pressure fluctuations and water hammer makes them an indispensable tool in fluid management systems. As industries continue to seek efficiency and reliability, the importance of such innovative designs will likely grow. Investing in check valves with counterweights can enhance operational efficiency, reduce costs, and ensure system longevity.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025