Jan . 14, 2025 11:27 Back to list

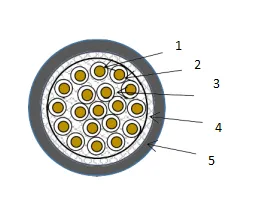

wire cable

Navigating the intricate world of wire cables requires a blend of expertise and keen understanding of the intricacies involved in their application and maintenance. Wire cables are a critical component across various industries, from telecommunications to construction, each demanding products tailored to specific technical parameters.

Incorporating wire cables into a project demands attention to quality and reliability. Certified suppliers should be sought out, with credentials that reflect compliance with international benchmarks such as ISO standards. Trustworthiness is further bolstered by positive reviews and longevity in the industry, indicating a track record of successful project integrations. Partnering with suppliers who offer technical support can also be an invaluable resource, providing expertise during both the selection process and post-installation phase. The environmental impact of wire cables should not be overlooked. As industries pivot towards sustainability, selecting cables with minimal ecological footprints is crucial. Environmentally-friendly cables, manufactured using recyclable materials and energy-efficient processes, contribute to a greener planet. Opt for companies actively working towards reducing waste and emissions in their manufacturing processes. Such choices not only reflect corporate responsibility but also align with growing legislative requirements and consumer expectations. In conclusion, wire cables are fundamental yet complex components. Making informed decisions based on thorough knowledge of materials, manufacturing processes, installation guidelines, and environmental impact ensures optimal functionality and sustainability. Engage with authoritative industry experts and selected suppliers to empower your project with the right wire cable solution that aligns with your specific needs and long-term vision.

Incorporating wire cables into a project demands attention to quality and reliability. Certified suppliers should be sought out, with credentials that reflect compliance with international benchmarks such as ISO standards. Trustworthiness is further bolstered by positive reviews and longevity in the industry, indicating a track record of successful project integrations. Partnering with suppliers who offer technical support can also be an invaluable resource, providing expertise during both the selection process and post-installation phase. The environmental impact of wire cables should not be overlooked. As industries pivot towards sustainability, selecting cables with minimal ecological footprints is crucial. Environmentally-friendly cables, manufactured using recyclable materials and energy-efficient processes, contribute to a greener planet. Opt for companies actively working towards reducing waste and emissions in their manufacturing processes. Such choices not only reflect corporate responsibility but also align with growing legislative requirements and consumer expectations. In conclusion, wire cables are fundamental yet complex components. Making informed decisions based on thorough knowledge of materials, manufacturing processes, installation guidelines, and environmental impact ensures optimal functionality and sustainability. Engage with authoritative industry experts and selected suppliers to empower your project with the right wire cable solution that aligns with your specific needs and long-term vision.

Share

Next:

Latest news

-

Priming a Pump with a Foot Valve with StrainerNewsAug.23,2025

-

The Importance of a Y Strainer in Pump ProtectionNewsAug.23,2025

-

Stainless Steel Ball Check Valve for High-Purity ApplicationsNewsAug.23,2025

-

Common Applications for Wafer Type Butterfly ValvesNewsAug.23,2025

-

Seat Options for a 12 Inch Knife Gate ValveNewsAug.23,2025

-

The Lifespan of a Typical Dismantling JointNewsAug.23,2025