ഫെബ്രു . 19, 2025 07:16 Back to list

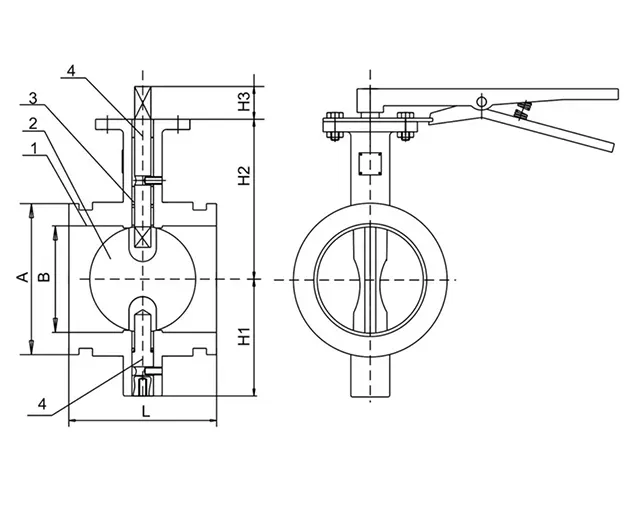

high performance wafer butterfly valve

Navigating the Complexities of Wafer Type Butterfly Valve Pricing

Technological and Operational Features Advanced technological integration can elevate the price of wafer type butterfly valves. Enhancements such as electric or pneumatic actuation, smart monitoring capabilities, and abrasion-resistant coatings offer improved performance and automation. These features, while increasing initial costs, contribute to substantial savings in labor and maintenance, optimizing operational efficiency. Businesses must assess the balance between advanced functional advantages and cost, aligning with their operational demands and technological infrastructure. Market Demand and Supply Dynamics The economic principles of demand and supply unequivocally influence wafer type butterfly valve prices. Regions with burgeoning industrial activities see higher demand, potentially elevating prices due to limited supply chains. Conversely, in regions with abundant supply chains, prices might stabilize or even reduce. Additionally, global economic factors, including raw material availability and transportation costs, further contribute to fluctuating prices. Analyzing these market dynamics can provide buyers with strategic insights into optimal purchasing times and locations. Brand Reputation and After-sales Service Though often overlooked, the brand reputation associated with wafer type butterfly valves plays a significant role in pricing. Renowned brands, known for product reliability and extensive after-sales service, charge premium prices. These brands offer warranties, maintenance support, and easy access to replacement parts, ensuring operational continuity. This reliability, coupled with professional technical support, adds immense value, translating to a comprehensive customer experience that justifies the investment. In conclusion, understanding the intricate factors that shape the pricing of wafer type butterfly valves involves a deep dive into material properties, technical features, compliance standards, and market ecosystems. Informed decision-making hinges on evaluating these variables in relation to specific industrial demands, ensuring that the selected valve delivers optimal function, endurance, and value for money. The wafer type butterfly valve exemplifies a component where price reflects a confluence of quality, technological advancement, and strategic market dynamics.

Technological and Operational Features Advanced technological integration can elevate the price of wafer type butterfly valves. Enhancements such as electric or pneumatic actuation, smart monitoring capabilities, and abrasion-resistant coatings offer improved performance and automation. These features, while increasing initial costs, contribute to substantial savings in labor and maintenance, optimizing operational efficiency. Businesses must assess the balance between advanced functional advantages and cost, aligning with their operational demands and technological infrastructure. Market Demand and Supply Dynamics The economic principles of demand and supply unequivocally influence wafer type butterfly valve prices. Regions with burgeoning industrial activities see higher demand, potentially elevating prices due to limited supply chains. Conversely, in regions with abundant supply chains, prices might stabilize or even reduce. Additionally, global economic factors, including raw material availability and transportation costs, further contribute to fluctuating prices. Analyzing these market dynamics can provide buyers with strategic insights into optimal purchasing times and locations. Brand Reputation and After-sales Service Though often overlooked, the brand reputation associated with wafer type butterfly valves plays a significant role in pricing. Renowned brands, known for product reliability and extensive after-sales service, charge premium prices. These brands offer warranties, maintenance support, and easy access to replacement parts, ensuring operational continuity. This reliability, coupled with professional technical support, adds immense value, translating to a comprehensive customer experience that justifies the investment. In conclusion, understanding the intricate factors that shape the pricing of wafer type butterfly valves involves a deep dive into material properties, technical features, compliance standards, and market ecosystems. Informed decision-making hinges on evaluating these variables in relation to specific industrial demands, ensuring that the selected valve delivers optimal function, endurance, and value for money. The wafer type butterfly valve exemplifies a component where price reflects a confluence of quality, technological advancement, and strategic market dynamics.

Share