ജനു . 26, 2025 01:40 Back to list

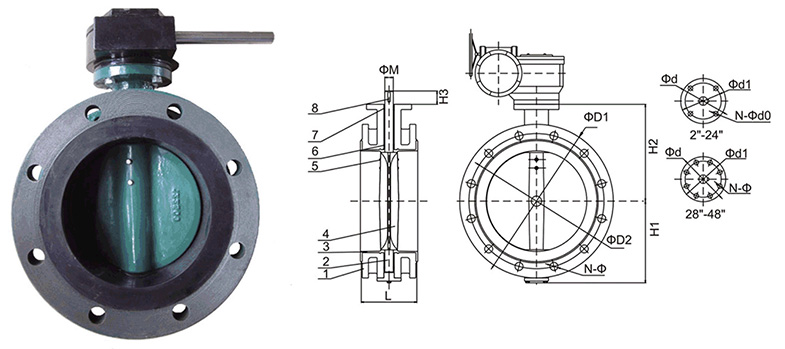

Wafer Type Butterfly Valve

Di air valves, a critical component in fluid control systems, enhance operational efficiency while ensuring safety across various industrial applications. With expertise rooted in years of practice and hands-on experience, this comprehensive guide delves into the intricacies of di air valves, showcasing their superiority in performance and reliability.

Trust in di air valves is not merely built on their robust engineering but also on the consistency of their performance over time. Regular maintenance, including scheduled inspections and cleaning, contributes significantly to their longevity. Adhering to manufacturer recommendations for service intervals maximizes the lifespan and efficacy of the di air valves, translating to reduced downtime and increased operational efficiency for businesses. Moreover, the expertise of manufacturers plays a vital role in the trustworthiness and authority of di air valves. Leading manufacturers commit substantial resources to research and development, ensuring that every valve produced is at the forefront of technology and innovation. Collaborating with a credible provider ensures access to cutting-edge designs, technical support, and bespoke solutions tailored to meet specific industrial challenges. In conclusion, di air valves are a testament to precision engineering and reliable performance, standing as a pivotal component in modern industrial operations. Their role in maintaining system equilibrium, coupled with their robust design, underscores their importance in safety and efficiency. With the right expertise in selection and maintenance, and guided by trustworthy manufacturers, di air valves not only meet but often exceed operational expectations, making them an invaluable asset in any fluid control system.

Trust in di air valves is not merely built on their robust engineering but also on the consistency of their performance over time. Regular maintenance, including scheduled inspections and cleaning, contributes significantly to their longevity. Adhering to manufacturer recommendations for service intervals maximizes the lifespan and efficacy of the di air valves, translating to reduced downtime and increased operational efficiency for businesses. Moreover, the expertise of manufacturers plays a vital role in the trustworthiness and authority of di air valves. Leading manufacturers commit substantial resources to research and development, ensuring that every valve produced is at the forefront of technology and innovation. Collaborating with a credible provider ensures access to cutting-edge designs, technical support, and bespoke solutions tailored to meet specific industrial challenges. In conclusion, di air valves are a testament to precision engineering and reliable performance, standing as a pivotal component in modern industrial operations. Their role in maintaining system equilibrium, coupled with their robust design, underscores their importance in safety and efficiency. With the right expertise in selection and maintenance, and guided by trustworthy manufacturers, di air valves not only meet but often exceed operational expectations, making them an invaluable asset in any fluid control system.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025