មករា . 09, 2025 11:17 Back to list

Gate Valve Solutions for Reliable Flow Control

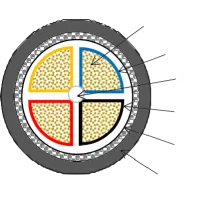

Gate valves, a cornerstone in the realm of fluid control systems, serve as indispensable components in various industrial applications. Their design and operation embody an excellent blend of innovation and practicality, offering clear advantages in controlling fluid flow with precision and reliability. As an established professional in the field, one cannot overlook the critical importance of understanding gate valves' operations, applications, and benefits.

In practical scenarios, users laud gate valves for their versatility and reliability. They require minimal maintenance, given their simplistic design, and exhibit a high degree of efficiency when integrated into large-scale systems. The linear motion of gate valves also expedites swift operation, providing an instantaneous response to control demands. Such features have become defining factors for industries that prioritize operational efficiency and resource management. Moreover, the trustworthiness of gate valves is demonstrated by their consistent performance in high-temperature and high-pressure environments. Industries like power generation and petrochemicals depend heavily on these valves to uphold safety and integrity in their processes. Continual innovations in design, such as pressure-sealed bonnets and resilient seats, further enhance their efficacy and safety, underscoring the confidence invested in these components. In the realm of fluid control, the authority of gate valves is undisputed. Their design simplicity, combined with performance reliability, assures users of their strategic value in both standard and challenging conditions. Professionals well-versed in fluid control underscore the importance of gate valves as not just products, but pivotal instruments in managing industrial operations with expertise. Gate valves are more than just industrial components—they represent the embodiment of efficiency and precision in fluid control systems. Their enduring relevance and adaptability across countless applications testify to their significance. Understanding and leveraging the capabilities of gate valves equip industries to tackle contemporary challenges with a refined sense of expertise and trust.

In practical scenarios, users laud gate valves for their versatility and reliability. They require minimal maintenance, given their simplistic design, and exhibit a high degree of efficiency when integrated into large-scale systems. The linear motion of gate valves also expedites swift operation, providing an instantaneous response to control demands. Such features have become defining factors for industries that prioritize operational efficiency and resource management. Moreover, the trustworthiness of gate valves is demonstrated by their consistent performance in high-temperature and high-pressure environments. Industries like power generation and petrochemicals depend heavily on these valves to uphold safety and integrity in their processes. Continual innovations in design, such as pressure-sealed bonnets and resilient seats, further enhance their efficacy and safety, underscoring the confidence invested in these components. In the realm of fluid control, the authority of gate valves is undisputed. Their design simplicity, combined with performance reliability, assures users of their strategic value in both standard and challenging conditions. Professionals well-versed in fluid control underscore the importance of gate valves as not just products, but pivotal instruments in managing industrial operations with expertise. Gate valves are more than just industrial components—they represent the embodiment of efficiency and precision in fluid control systems. Their enduring relevance and adaptability across countless applications testify to their significance. Understanding and leveraging the capabilities of gate valves equip industries to tackle contemporary challenges with a refined sense of expertise and trust.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025