jan . 20, 2025 00:52 Back to list

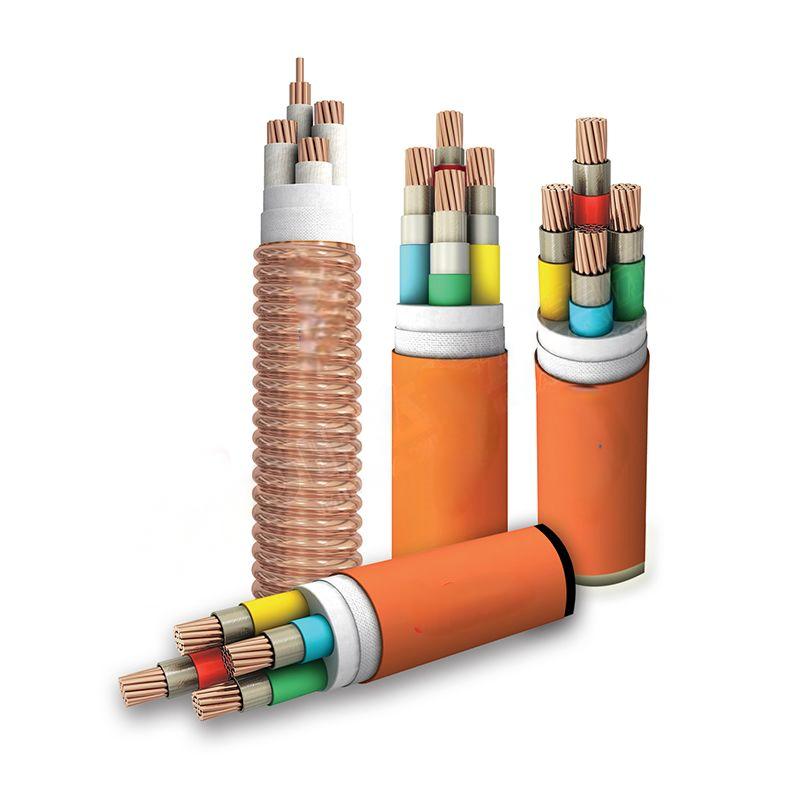

ground cable wire

The significance of ground cable wire in modern electrical systems cannot be overstated. An often-underestimated component, ground cable wire is crucial for ensuring electrical safety and system integrity in a wide range of environments, from residential homes to industrial facilities. A robust understanding of its function and application can significantly aid in making informed purchasing and installation decisions that can enhance electrical safety and performance.

The insulation type also plays a pivotal role in ground cable wire selection. For outdoor or buried applications, wires often require a robust, weather-resistant insulation to prevent environmental degradation, which can compromise functionality. Polyvinyl chloride (PVC) is a common choice for its cost-effectiveness and durability, while cross-linked polyethylene (XLPE) offers superior heat and chemical resistance, making it suitable for more extreme conditions. A credible source in the domain of electrical systems will emphasize these technical details while also stressing the importance of compliance with local and international electrical codes. These codes ensure that all installations meet safety and quality standards, reducing the risk of electrical hazards. Consulting with a certified electrician or electrical engineer is advisable when determining the specifications for your ground cable wiring needs. Their expertise assures that installations are both effective and compliant with regulatory standards. Real-world experiences underscore the importance of quality and compliance in ground cable wire selection. Several case studies highlight failures due to substandard materials or improper installations leading to severe damage and financial loss. On the contrary, success stories where proper specifications and quality materials were used demonstrate long-term reliability and safety, reinforcing best practices in wire selection and application. In conclusion, while ground cable wire might appear to be a minor component in electrical systems, its impact on safety and functionality cannot be minimized. By focusing on the factors outlined above—material, gauge, and insulation type—combined with adherence to safety standards and real-world insights, individuals and businesses can make sound decisions that protect people, property, and investments. A commitment to quality, informed by expert opinions and lived experiences, ensures the safe and efficient operation of electrical systems in a myriad of environments.

The insulation type also plays a pivotal role in ground cable wire selection. For outdoor or buried applications, wires often require a robust, weather-resistant insulation to prevent environmental degradation, which can compromise functionality. Polyvinyl chloride (PVC) is a common choice for its cost-effectiveness and durability, while cross-linked polyethylene (XLPE) offers superior heat and chemical resistance, making it suitable for more extreme conditions. A credible source in the domain of electrical systems will emphasize these technical details while also stressing the importance of compliance with local and international electrical codes. These codes ensure that all installations meet safety and quality standards, reducing the risk of electrical hazards. Consulting with a certified electrician or electrical engineer is advisable when determining the specifications for your ground cable wiring needs. Their expertise assures that installations are both effective and compliant with regulatory standards. Real-world experiences underscore the importance of quality and compliance in ground cable wire selection. Several case studies highlight failures due to substandard materials or improper installations leading to severe damage and financial loss. On the contrary, success stories where proper specifications and quality materials were used demonstrate long-term reliability and safety, reinforcing best practices in wire selection and application. In conclusion, while ground cable wire might appear to be a minor component in electrical systems, its impact on safety and functionality cannot be minimized. By focusing on the factors outlined above—material, gauge, and insulation type—combined with adherence to safety standards and real-world insights, individuals and businesses can make sound decisions that protect people, property, and investments. A commitment to quality, informed by expert opinions and lived experiences, ensures the safe and efficient operation of electrical systems in a myriad of environments.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025