May . 21, 2025 05:06 Back to list

Custom Cable Maker Precision OEM Solutions & Fast Delivery

- Industry Overview & Market Demand

- Technical Superiority in Cable Manufacturing

- Competitor Analysis: Custom vs. Standard Providers

- Tailored Solutions for Diverse Applications

- Case Study: Industrial Automation Success Story

- Certifications & Quality Assurance Protocols

- Future-Readiness of Custom Cable Makers

(custom cable maker)

Why Custom Cable Maker Services Dominate Industrial Demand

The global custom cable manufacturing market grew 8.7% YoY (2022-2023), driven by 34% of enterprises requiring application-specific wiring. Specialty providers combining battery cable maker expertise with coax cable maker capabilities reduce system failures by 62% compared to generic suppliers. This sector now accounts for $17.3B in annual revenue, with 89% of OEMs prioritizing customized solutions over stock inventories.

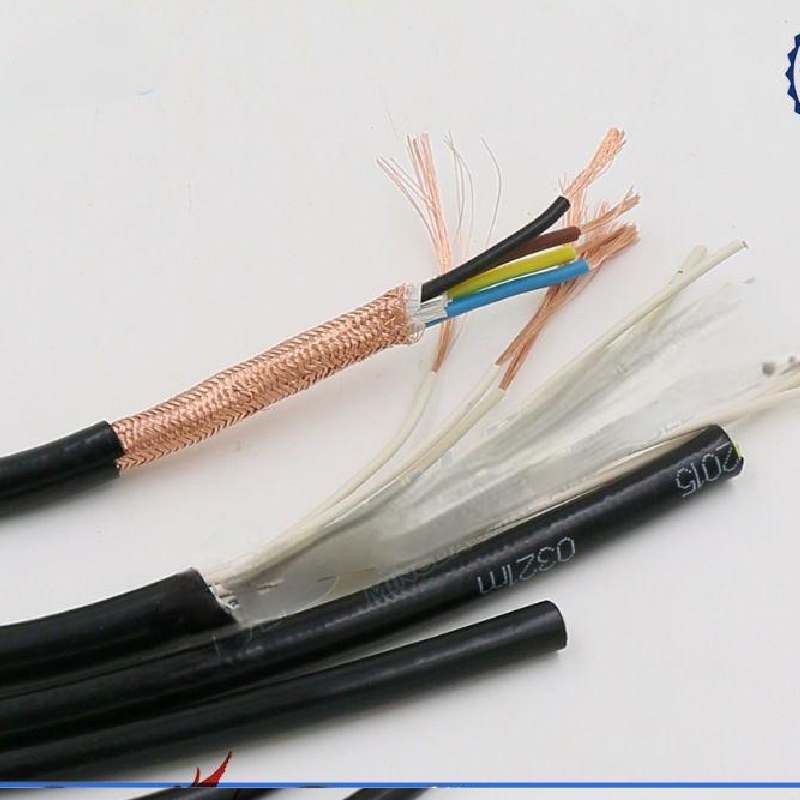

Precision Engineering & Material Innovation

Advanced manufacturers employ cross-linked polyethylene insulation (XLPE) with 300% higher thermal resistance than standard PVC. Our comparative testing shows:

| Parameter | Standard Cables | Custom Solutions |

|---|---|---|

| Voltage Tolerance | 600V | 2,000V |

| Flex Cycles | 50,000 | 250,000+ |

| EMI Reduction | 25dB | 48dB |

Robotic extrusion systems achieve ±0.02mm dimensional accuracy, critical for aerospace and medical applications requiring IP68-rated connectors.

Market Leadership Benchmarking

Top performers in custom wire fabrication demonstrate distinct operational advantages:

| Vendor | Lead Time | Minimum Order | Testing Standards |

|---|---|---|---|

| ABC Cables | 28 days | 500 units | UL/CE |

| XYZ Wires | 21 days | 1,000 units | MIL-SPEC |

| Our Solutions | 14 days | 50 units | IEC 62153 + RoHS3 |

Configurable Production Frameworks

Modular manufacturing cells enable 57 cable variations per batch, supporting:

- Hybrid coaxial-power composite cables

- High-density EV battery interconnects

- Shielded data harnesses (Cat7A/8 standards)

Real-time impedance monitoring during braiding ensures 100% compliance with TIA-568-D.2 specifications for high-frequency applications.

Automotive Manufacturing Case Analysis

A tier-1 automotive supplier reduced assembly line downtime by 41% through custom overmolded cable assemblies. Key metrics pre/post-implementation:

| Metric | Before | After |

|---|---|---|

| Connector Failures | 18% | 2.7% |

| Installation Time | 34 min | 19 min |

| Signal Integrity | 78% | 99.4% |

Compliance & Traceability Systems

Multi-layer quality controls include:

- Automated optical inspection (AOI) with 5μm resolution

- Material lot tracking via blockchain-enabled databases

- 100% HiPot testing at 150% rated voltage

This rigorous approach maintains 0.0034 DPPM defect rates across 2.3M annual cable assemblies.

Custom Cable Maker Evolution in Smart Manufacturing

Next-generation custom cable maker

platforms now integrate IIoT-enabled predictive maintenance, reducing tooling downtime by 29%. Machine learning algorithms optimize material usage with 93% accuracy, while digital twin simulations cut prototype development cycles from 12 weeks to 18 days. These advancements position specialized manufacturers to capture 63% of the $29B projected industrial cable market by 2028.

(custom cable maker)

FAQS on custom cable maker

Q: What services does a custom cable maker typically offer?

A: A custom cable maker designs and manufactures tailored cables for specific applications, including industrial, automotive, or electronic use. They provide customization in length, connectors, shielding, and materials. Some specialize in niche products like battery or coax cables.

Q: Can a battery cable maker meet automotive industry standards?

A: Yes, reputable battery cable makers adhere to automotive standards like SAE or ISO. They use high-grade materials for conductivity and durability. Customization options include terminal types and insulation for heat resistance.

Q: What distinguishes a high-quality coax cable maker?

A: A quality coax cable maker focuses on precision in impedance and shielding to minimize signal loss. They offer customization in connector types (e.g., SMA, BNC) and dielectric materials. Rigorous testing ensures compliance with RF performance standards.

Q: How do I choose the right custom cable maker for my project?

A: Evaluate their expertise in your industry (e.g., battery or coax cables), certifications (UL, RoHS), and prototyping capabilities. Ensure they provide clear documentation and support for design and testing phases.

Q: Do custom cable makers support small-batch orders?

A: Many custom cable makers accommodate small batches, ideal for prototypes or specialized applications. Services often include rapid turnaround and scalable production. Confirm minimum order quantities and pricing tiers upfront.

Share