Jan . 09, 2025 13:49 Back to list

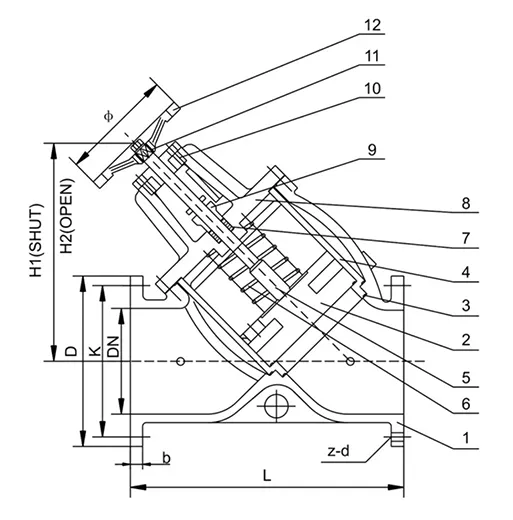

Wafer Type Butterfly Valve

Industrial valves play a crucial role in a myriad of sectors, from oil and gas to water and wastewater management. Understanding what makes an industrial valve reliable and efficient can ensure optimal system performance, thus offering a competitive edge in demanding markets. The following insights into industrial valve considerations provide a comprehensive exploration designed to enhance your decision-making process when selecting the best valve for your applications.

Integrating smart technologies into industrial valves is becoming an industry standard. With the rise of Industry 4.0, smart valves capable of remote monitoring and data collection are increasingly essential. These devices can transmit real-time data regarding flow rates, pressure, and valve positioning, thus allowing predictive maintenance and enhancing overall system reliability. Investing in smart valves can position your operations at the forefront of technological advancements, offering a strategic advantage in anticipating system failures before they result in costly disruptions. In addition to technical specifications, supplier selection is critical in ensuring valve reliability and quality. Engage with suppliers who demonstrate a solid track record of expertise in your specific industrial domain. They should provide clear and comprehensive documentation, offer post-sale support, and understand the unique challenges of your industry. An established, reliable supplier will often extend warranties and provide detailed user manuals, which are indicators of their confidence in their products and their commitment to customer satisfaction. Finally, remember that trustworthiness in the realm of industrial valves stems from transactional transparency and communication. A dependable partner will prioritize client relationships, ensuring continuous updates on product innovations and developments in valve technologies. Their openness to feedback and agility to improve bespoke solutions is a testament to their dedication to meeting industry demands and enhancing customer satisfaction. In conclusion, selecting an industrial valve involves a meticulous assessment of performance criteria, regulatory compliance, technological integration, and supplier credibility. Industrial success relies on each component operating seamlessly and efficiently, making the right valve an indispensable link in the operational chain. Mastery of these details positions you not only as a connoisseur of industrial components but as a custodian of system excellence.

Integrating smart technologies into industrial valves is becoming an industry standard. With the rise of Industry 4.0, smart valves capable of remote monitoring and data collection are increasingly essential. These devices can transmit real-time data regarding flow rates, pressure, and valve positioning, thus allowing predictive maintenance and enhancing overall system reliability. Investing in smart valves can position your operations at the forefront of technological advancements, offering a strategic advantage in anticipating system failures before they result in costly disruptions. In addition to technical specifications, supplier selection is critical in ensuring valve reliability and quality. Engage with suppliers who demonstrate a solid track record of expertise in your specific industrial domain. They should provide clear and comprehensive documentation, offer post-sale support, and understand the unique challenges of your industry. An established, reliable supplier will often extend warranties and provide detailed user manuals, which are indicators of their confidence in their products and their commitment to customer satisfaction. Finally, remember that trustworthiness in the realm of industrial valves stems from transactional transparency and communication. A dependable partner will prioritize client relationships, ensuring continuous updates on product innovations and developments in valve technologies. Their openness to feedback and agility to improve bespoke solutions is a testament to their dedication to meeting industry demands and enhancing customer satisfaction. In conclusion, selecting an industrial valve involves a meticulous assessment of performance criteria, regulatory compliance, technological integration, and supplier credibility. Industrial success relies on each component operating seamlessly and efficiently, making the right valve an indispensable link in the operational chain. Mastery of these details positions you not only as a connoisseur of industrial components but as a custodian of system excellence.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025