ફેબ્રુવારી . 15, 2025 18:09 Back to list

Ball Check Valve

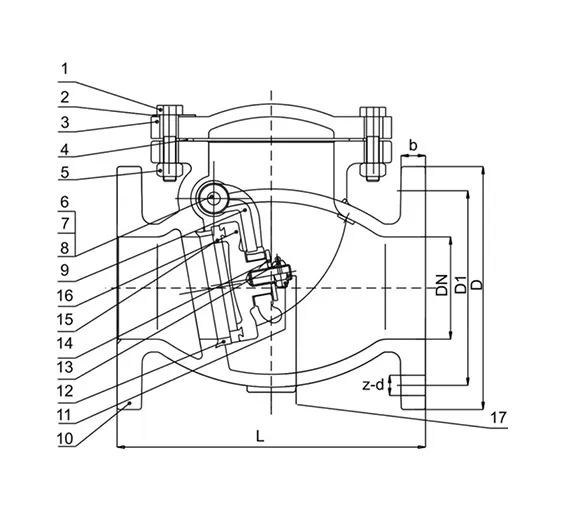

Understanding the significance of check valves is crucial for anyone involved in fluid dynamics or mechanical engineering, especially when it comes to ensuring efficiency and safety in systems. Among various types, check valves with counterweights are renowned for their effectiveness in controlling fluid flow while offering precise operation under specific conditions.

Trustworthiness in operation is another hallmark of the check valve with a counterweight. By focusing on long-term performance and reduced maintenance needs, operators can place greater confidence in their systems. Routine inspections are made simpler thanks to the straightforward mechanics involved; adjustments to the counterweight, when necessary, are easily accomplished, thereby decreasing downtime and operational costs. Real-world applications showcase remarkable outcomes. For instance, a Midwest water authority in the United States adopted counterweight check valves in their wastewater management system. This transition led to a 20% reduction in maintenance costs over three years, primarily due to decreased instances of valve failure and pipe bursts previously caused by check valve malfunctions. In corporate settings, engineers tasked with designing fluid handling systems are increasingly advocating for counterweighted check valves, citing them as essential components for innovative, sustainable designs. Companies aiming for certifications, like LEED or ISO environmental standards, find that the reliability and efficiency of these valves contribute positively towards achieving their sustainability goals. When considering the selection of a check valve with a counterweight, consultation with seasoned professionals and thorough evaluation of the system's specific needs are recommended. Comparative analyses between various brands and models should be conducted, focusing on factors like material compatibility, flow dynamics, installation requirements, and manufacturer reputation. Opting for a well-established brand known for its commitment to excellence can further enhance system reliability. In conclusion, check valves with counterweights represent a strategic investment in achieving optimal flow control within complex systems. Their ability to provide consistent performance under challenging circumstances makes them a favored choice among industry veterans and engineers. Prioritizing quality and compatibility, along with staying informed about the latest innovations in valve technology, ensures that these components continue to safeguard operations across various sectors.

Trustworthiness in operation is another hallmark of the check valve with a counterweight. By focusing on long-term performance and reduced maintenance needs, operators can place greater confidence in their systems. Routine inspections are made simpler thanks to the straightforward mechanics involved; adjustments to the counterweight, when necessary, are easily accomplished, thereby decreasing downtime and operational costs. Real-world applications showcase remarkable outcomes. For instance, a Midwest water authority in the United States adopted counterweight check valves in their wastewater management system. This transition led to a 20% reduction in maintenance costs over three years, primarily due to decreased instances of valve failure and pipe bursts previously caused by check valve malfunctions. In corporate settings, engineers tasked with designing fluid handling systems are increasingly advocating for counterweighted check valves, citing them as essential components for innovative, sustainable designs. Companies aiming for certifications, like LEED or ISO environmental standards, find that the reliability and efficiency of these valves contribute positively towards achieving their sustainability goals. When considering the selection of a check valve with a counterweight, consultation with seasoned professionals and thorough evaluation of the system's specific needs are recommended. Comparative analyses between various brands and models should be conducted, focusing on factors like material compatibility, flow dynamics, installation requirements, and manufacturer reputation. Opting for a well-established brand known for its commitment to excellence can further enhance system reliability. In conclusion, check valves with counterweights represent a strategic investment in achieving optimal flow control within complex systems. Their ability to provide consistent performance under challenging circumstances makes them a favored choice among industry veterans and engineers. Prioritizing quality and compatibility, along with staying informed about the latest innovations in valve technology, ensures that these components continue to safeguard operations across various sectors.

Share

Latest news

-

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025