Feb . 18, 2025 10:04 Back to list

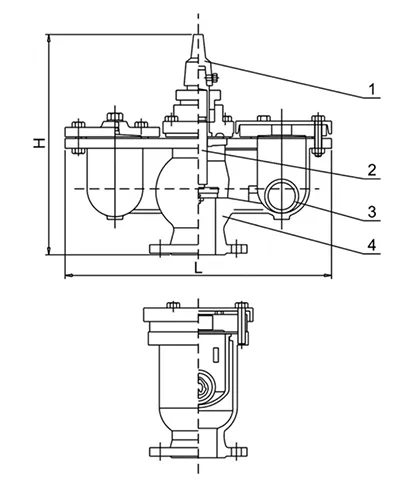

Ball Check Valve

In the industrial world, where fluid dynamics and material handling are critical, the floating ball check valve emerges as a pivotal component. This valve, designed to prevent backflow in piping systems, is indispensable across various sectors ranging from chemical processing plants to water management systems. Understanding its dynamics provides insights into its importance and capabilities in modern engineering and infrastructure.

From an expert's perspective, the importance of regular maintenance cannot be overstated, even with the inherently reliable design of the floating ball check valve. Routine checks and cleaning ensure debris does not hinder the valve's operation, thus maintaining optimal performance and prolonging the valve's lifespan. This proactive maintenance approach epitomizes the principles of industry best practices, safeguarding against unexpected system failures. Beyond its structural and operational advantages, the floating ball check valve plays a crucial role in maintaining safety standards within industrial operations. Its ability to prevent backflow is vital in mitigating risks associated with cross-contamination or system overpressurization, which, if unchecked, could lead to catastrophic failures. By ensuring one-directional flow, these valves uphold the integrity of sensitive processes and environmental regulations. The reliability and functionality of the floating ball check valve are not only embraced by industry practitioners but are also substantiated by authoritative bodies in fluid dynamics and engineering. These endorsements are a testament to the valve’s efficacy and underpin its widespread adoption across industries. Trust in this technology is further solidified by countless successful applications that demonstrate resilience and performance under varying operational stresses. Innovation in floating ball check valve technology continues, with manufacturers exploring advanced materials and smart integration features to further enhance efficiency and adaptability. These forward-looking advancements will likely open new avenues and applications, further solidifying the valve’s role in future-proofing industrial infrastructure. In summary, the floating ball check valve is more than just a flow control device; it is a critical component that harmonizes efficiency, safety, and reliability. For industry professionals, the integration of this valve into fluid systems represents a commitment to excellence in operational standards and a dedication to utilizing components that embody engineering prowess and innovation. As industries evolve, the floating ball check valve remains steadfast in its purpose, a true testament to its engineering significance.

From an expert's perspective, the importance of regular maintenance cannot be overstated, even with the inherently reliable design of the floating ball check valve. Routine checks and cleaning ensure debris does not hinder the valve's operation, thus maintaining optimal performance and prolonging the valve's lifespan. This proactive maintenance approach epitomizes the principles of industry best practices, safeguarding against unexpected system failures. Beyond its structural and operational advantages, the floating ball check valve plays a crucial role in maintaining safety standards within industrial operations. Its ability to prevent backflow is vital in mitigating risks associated with cross-contamination or system overpressurization, which, if unchecked, could lead to catastrophic failures. By ensuring one-directional flow, these valves uphold the integrity of sensitive processes and environmental regulations. The reliability and functionality of the floating ball check valve are not only embraced by industry practitioners but are also substantiated by authoritative bodies in fluid dynamics and engineering. These endorsements are a testament to the valve’s efficacy and underpin its widespread adoption across industries. Trust in this technology is further solidified by countless successful applications that demonstrate resilience and performance under varying operational stresses. Innovation in floating ball check valve technology continues, with manufacturers exploring advanced materials and smart integration features to further enhance efficiency and adaptability. These forward-looking advancements will likely open new avenues and applications, further solidifying the valve’s role in future-proofing industrial infrastructure. In summary, the floating ball check valve is more than just a flow control device; it is a critical component that harmonizes efficiency, safety, and reliability. For industry professionals, the integration of this valve into fluid systems represents a commitment to excellence in operational standards and a dedication to utilizing components that embody engineering prowess and innovation. As industries evolve, the floating ball check valve remains steadfast in its purpose, a true testament to its engineering significance.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025