Gearr . 17, 2025 13:54 Back to list

Knife Gate Valve

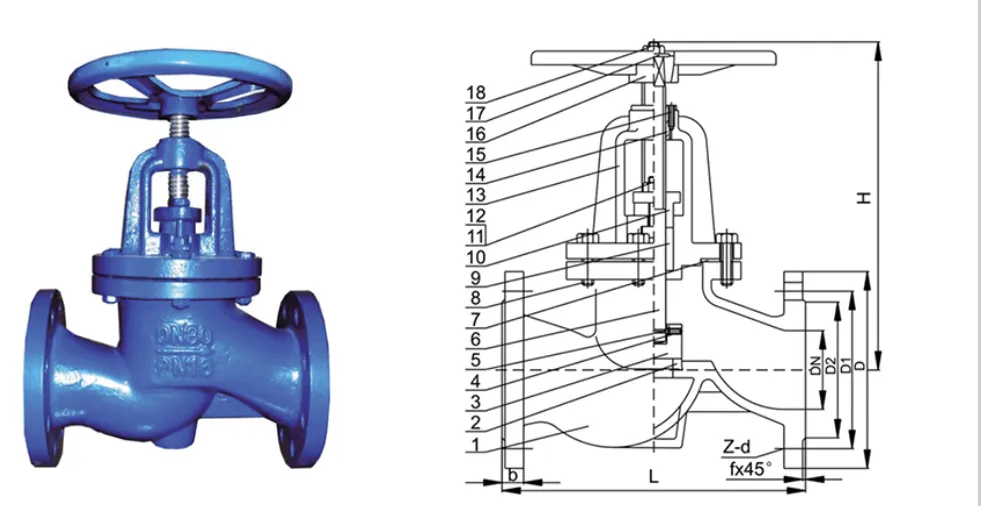

Flanged gate valves are essential components in fluid control systems across various industries. Known for their robust design and reliable operation, these valves are engineered to offer optimal performance in demanding environments. Their construction and functionality make them suitable for a wide range of applications, from water and wastewater treatment to chemical processing and power generation.

The expertise in the design and manufacture of flanged gate valves extends to their operational advantages. Unlike some valve types that throttle flow, gate valves are designed specifically for starting or stopping flow. Their full-bore design means that when the valve is fully open, there is minimal resistance to flow, reducing pressure drop and ensuring efficient fluid transfer. This characteristic is particularly beneficial in applications where energy efficiency is a priority. Real-world experience and customer feedback consistently highlight the benefits of utilizing flanged gate valves in complex systems. Industries that require precision, such as the oil and gas sector, have repeatedly demonstrated successful implementation of these valves in their systems. Operators appreciate the low torque requirement for operation, which reduces the wear on the valve and the manual effort needed to operate it. Furthermore, the longevity of flanged gate valves is a significant advantage. With proper maintenance, these valves can remain in service for many years, providing a cost-effective solution over their lifecycle. Users report that the occasional need for seal replacement or lubrication is a small price to pay for the continued operational efficiency and reliability these valves provide. In summary, flanged gate valves are a critical asset in modern industrial applications. Their design, grounded in expert engineering, ensures they meet the high standards required in demanding environments. By choosing valves that comply with international standards and are constructed from quality materials, industries can rely on their performance and durability. This level of trust not only enhances operational efficiency but also provides the assurance that safety and compliance are upheld, reinforcing the valve's authoritative standing in the market.

The expertise in the design and manufacture of flanged gate valves extends to their operational advantages. Unlike some valve types that throttle flow, gate valves are designed specifically for starting or stopping flow. Their full-bore design means that when the valve is fully open, there is minimal resistance to flow, reducing pressure drop and ensuring efficient fluid transfer. This characteristic is particularly beneficial in applications where energy efficiency is a priority. Real-world experience and customer feedback consistently highlight the benefits of utilizing flanged gate valves in complex systems. Industries that require precision, such as the oil and gas sector, have repeatedly demonstrated successful implementation of these valves in their systems. Operators appreciate the low torque requirement for operation, which reduces the wear on the valve and the manual effort needed to operate it. Furthermore, the longevity of flanged gate valves is a significant advantage. With proper maintenance, these valves can remain in service for many years, providing a cost-effective solution over their lifecycle. Users report that the occasional need for seal replacement or lubrication is a small price to pay for the continued operational efficiency and reliability these valves provide. In summary, flanged gate valves are a critical asset in modern industrial applications. Their design, grounded in expert engineering, ensures they meet the high standards required in demanding environments. By choosing valves that comply with international standards and are constructed from quality materials, industries can rely on their performance and durability. This level of trust not only enhances operational efficiency but also provides the assurance that safety and compliance are upheld, reinforcing the valve's authoritative standing in the market.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025