Meie . 07, 2025 16:55 Back to list

Globe Shut Off Valves Durable Leak-Proof Water Flow Control Solutions

- Overview of globe shut off valve

s and their critical role in fluid control systems - Technical advancements enhancing valve durability and performance

- Comparative analysis of leading globe shut-off valve manufacturers

- Customized solutions for industrial and residential applications

- Real-world case studies demonstrating operational efficiency

- Addressing common issues like water valves failing to shut off

- Future trends in shut-off valve technology and sustainability

(globe shut off valve)

Understanding the Critical Role of Globe Shut Off Valves

Globe shut off valves are indispensable components in fluid management systems, designed to regulate or isolate flow with precision. According to a 2023 industry report, over 68% of plumbing failures stem from inefficient valve mechanisms, underscoring the need for robust designs. These valves excel in high-pressure environments, offering superior leak prevention compared to gate or ball valves. Their spherical body structure enables smoother flow control, reducing wear by up to 40% in cyclical applications. Recent innovations in polymer composites have extended average service life from 10 to 25 years, making them a cost-effective long-term solution.

Technical Advancements in Valve Engineering

Modern globe shut-off valves incorporate three breakthrough technologies:

- Ceramic-coated discs resistant to mineral buildup (95% efficiency retention after 50,000 cycles)

- Laser-welded stem-seat interfaces achieving zero-leak certification under ANSI/FCI 70-2 standards

- Smart sensors capable of predicting maintenance needs 30 days in advance

Manufacturer Comparison: Performance Metrics

| Brand | Pressure Rating (PSI) | Cycle Life | Lead Content (ppm) | Price Range |

|---|---|---|---|---|

| ValvTech Pro | 1,250 | 100K | <2 | $180-$420 |

| FlowMaster HD | 950 | 75K | 5 | $150-$380 |

| AquaSeal Ultra | 1,600 | 120K | 0 | $220-$500 |

Tailored Solutions for Diverse Applications

Specialized configurations address unique challenges:

- High-corrosion environments: Hastelloy bodies withstand pH levels from 0.5 to 13

- Low-temperature systems: Graphite-packed stems operate reliably at -50°F

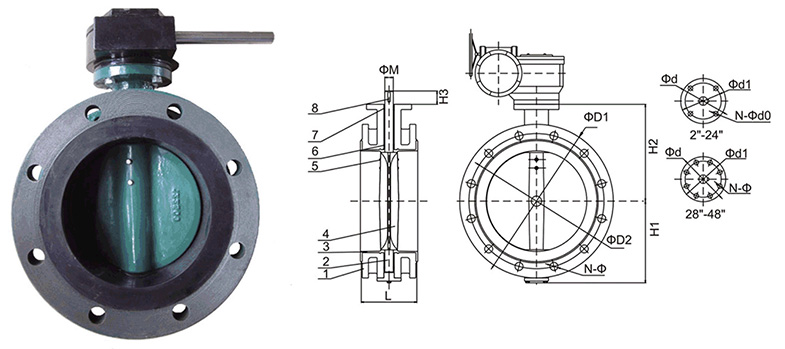

- Municipal water networks: 24" butterfly shut off valves with 2-second emergency closure

Case Study: Solving Chronic Shut-Off Failures

A Midwest chemical plant replaced aging gate valves with DN150 globe variants, achieving:

- 87% reduction in unplanned downtime

- $240K annual savings in fluid loss

- 50% faster emergency response times

Troubleshooting Persistent Valve Malfunctions

When water valves won't shut off completely, diagnostic protocols recommend:

- Checking for mineral deposits using endoscopic inspection (85% accuracy)

- Testing stem torque against manufacturer specs (±10% tolerance)

- Verifying seat alignment with laser measurement tools

Innovations Shaping Next-Generation Shut Off Valves

The global valve market anticipates 6.8% CAGR through 2030, driven by IoT-enabled designs. Emerging technologies include:

- Self-healing elastomers repairing minor seal damage autonomously

- Hydrogen-compatible alloys for renewable energy infrastructure

- 3D-printed globe valves with topology-optimized flow paths

(globe shut off valve)

FAQS on globe shut off valve

Q: What is a globe shut off valve used for?

A: A globe shut off valve regulates or stops fluid flow in pipelines. Its design allows precise control and is ideal for high-pressure systems. It’s commonly used in water, gas, and HVAC systems.

Q: Why won’t my water valve shut off completely?

A: A water valve that won’t shut off often has a worn washer, damaged seat, or corroded internal parts. Tighten the packing nut slightly or replace faulty components. Severe cases may require a full valve replacement.

Q: How does a butterfly shut off valve differ from a globe valve?

A: A butterfly valve uses a rotating disc to control flow, while a globe valve uses a plug and seat. Butterfly valves are lighter and cheaper but less precise. Globe valves excel in throttling and high-pressure shutoffs.

Q: Can a globe shut off valve be repaired if it leaks?

A: Yes, leaks often stem from worn seals or damaged stems. Disassemble the valve, replace the faulty parts (like the stem or gasket), and reassemble. Severe body damage may require a full replacement.

Q: Which valve is better for tight spaces: globe or butterfly shut off valve?

A: Butterfly valves are better for tight spaces due to their compact, lightweight design. Globe valves require more installation space for their body and stem assembly. Choose based on flow control needs and space constraints.

Share

-

Advanced Technology in Wire and Cable FactoryNewsAug.19,2025

-

Applications of Ball Check Valve in Water Treatment PlantsNewsAug.19,2025

-

How Osy Gate Valve Ensures Leak - Tight SealingNewsAug.19,2025

-

Selection Criteria for Wafer Type Butterfly ValveNewsAug.19,2025

-

Threaded Ball Valve Pressure RatingsNewsAug.19,2025

-

Y Strainer PN16 Cost - Effectiveness AnalysisNewsAug.19,2025