Peb . 20, 2025 01:18 Back to list

swing type check valve

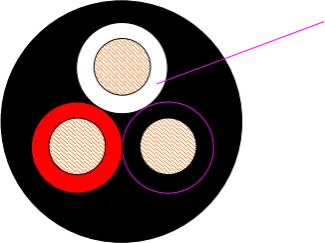

Swing type check valves are integral components in various industrial systems, renowned for their reliability and efficiency in preventing backflow. These valves operate through a simple yet effective mechanism that involves a swinging disc, typically made of metal or other durable material, which responds to changes in fluid flow. When fluid flows in the intended direction, the disc swings open, allowing passage. Conversely, any attempt of reverse flow causes the disc to close, effectively sealing the passage and preventing any backflow.

Trustworthiness in swing type check valve systems is enhanced by the traceability of the materials and components used in their construction. Leading companies offer full transparency in their manufacturing processes, providing end users with the confidence that the valves meet stringent industry standards. Additionally, warranties and after-sales support services are vital components that underscore a manufacturer's commitment to trustworthiness, ensuring that any issues are promptly addressed and resolved. Incorporating swing type check valves into a system involves not merely purchasing and installation but also understanding the nuances of their operation and maintenance. System operators benefit from detailed training sessions offered by manufacturers or authorized distributors, which demystify the operating principles and maintenance routines. This hands-on training translates into smoother operations and enhances the operators' ability to quickly diagnose and rectify any issues that may arise. Finally, the environmental impact of swing type check valves is noteworthy. These valves contribute significantly to reducing emissions and operational waste in industrial systems. By effectively preventing leaks and ensuring smooth flow control, they help in maintaining system integrity and environmental compliance, vital in today's eco-conscious industrial landscape. In conclusion, swing type check valves stand as a testament to engineering simplicity combined with operational efficiency. Their broad application range, cost-effectiveness, and contribution to sustainable industrial practices make them indispensable in various sectors. Whether water management or chemical processing, these valves continue to be a cornerstone of fluid control systems worldwide. The continuous improvements in materials and design usher in a future where swing type check valves will only gain more prominence, reinforcing their essential role in industrial operations.

Trustworthiness in swing type check valve systems is enhanced by the traceability of the materials and components used in their construction. Leading companies offer full transparency in their manufacturing processes, providing end users with the confidence that the valves meet stringent industry standards. Additionally, warranties and after-sales support services are vital components that underscore a manufacturer's commitment to trustworthiness, ensuring that any issues are promptly addressed and resolved. Incorporating swing type check valves into a system involves not merely purchasing and installation but also understanding the nuances of their operation and maintenance. System operators benefit from detailed training sessions offered by manufacturers or authorized distributors, which demystify the operating principles and maintenance routines. This hands-on training translates into smoother operations and enhances the operators' ability to quickly diagnose and rectify any issues that may arise. Finally, the environmental impact of swing type check valves is noteworthy. These valves contribute significantly to reducing emissions and operational waste in industrial systems. By effectively preventing leaks and ensuring smooth flow control, they help in maintaining system integrity and environmental compliance, vital in today's eco-conscious industrial landscape. In conclusion, swing type check valves stand as a testament to engineering simplicity combined with operational efficiency. Their broad application range, cost-effectiveness, and contribution to sustainable industrial practices make them indispensable in various sectors. Whether water management or chemical processing, these valves continue to be a cornerstone of fluid control systems worldwide. The continuous improvements in materials and design usher in a future where swing type check valves will only gain more prominence, reinforcing their essential role in industrial operations.

Share

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025