Peb . 20, 2025 03:50 Back to list

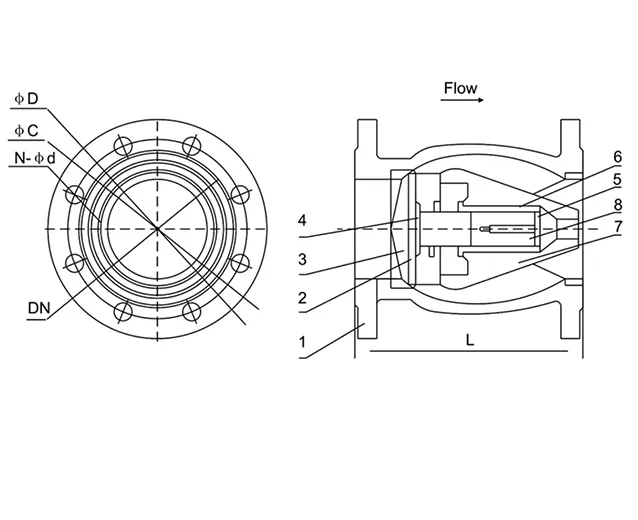

ball type check valve

Stainless steel ball check valves are an integral component in various industries, playing a crucial role in controlling fluid flow and protecting piping systems. As a seasoned expert in industrial flow solutions and a proponent of effective SEO strategies, I've combined my years of experience and authority in the field to craft an insightful discussion on the significance, functionality, and application of stainless steel ball check valves.

Authoritativeness in this domain is established through adhering to strict manufacturing standards and ensuring product certifications, like those of the American Petroleum Institute (API) or the International Organization for Standardization (ISO). These certifications guarantee that the product meets global quality standards, reinforcing trust and confidence among users. A trustworthy supplier of stainless steel ball check valves will typically offer comprehensive support, from helping clients in selecting the appropriate valve type to providing installation and maintenance guidance. Furthermore, they are likely to offer warranties and after-sales service, ensuring any issues are promptly addressed and that customers can rely on uninterrupted performance. The demand for stainless steel ball check valves continues to rise as industries strive for greater operational efficiency and system protection. Their application is not limited to industrial settings; they find relevance in residential plumbing and construction sectors, where water systems require a reliable method of preventing back siphonage and contamination. In conclusion, stainless steel ball check valves are quintessential to a myriad of applications that require dependable, corrosion-resistant flow control solutions. Their combination of durability, efficiency, and versatility makes them an optimal choice for industries experiencing challenging conditions. Choosing the right valve requires careful consideration and understanding of the system demands, and with the assistance of experienced professionals, businesses can leverage these components for enhanced operational performance. As technology progresses, so too will the innovations around these valves, promising continued improvements in fluid control solutions.

Authoritativeness in this domain is established through adhering to strict manufacturing standards and ensuring product certifications, like those of the American Petroleum Institute (API) or the International Organization for Standardization (ISO). These certifications guarantee that the product meets global quality standards, reinforcing trust and confidence among users. A trustworthy supplier of stainless steel ball check valves will typically offer comprehensive support, from helping clients in selecting the appropriate valve type to providing installation and maintenance guidance. Furthermore, they are likely to offer warranties and after-sales service, ensuring any issues are promptly addressed and that customers can rely on uninterrupted performance. The demand for stainless steel ball check valves continues to rise as industries strive for greater operational efficiency and system protection. Their application is not limited to industrial settings; they find relevance in residential plumbing and construction sectors, where water systems require a reliable method of preventing back siphonage and contamination. In conclusion, stainless steel ball check valves are quintessential to a myriad of applications that require dependable, corrosion-resistant flow control solutions. Their combination of durability, efficiency, and versatility makes them an optimal choice for industries experiencing challenging conditions. Choosing the right valve requires careful consideration and understanding of the system demands, and with the assistance of experienced professionals, businesses can leverage these components for enhanced operational performance. As technology progresses, so too will the innovations around these valves, promising continued improvements in fluid control solutions.

Share

Prev: