gen. . 25, 2025 05:18 Back to list

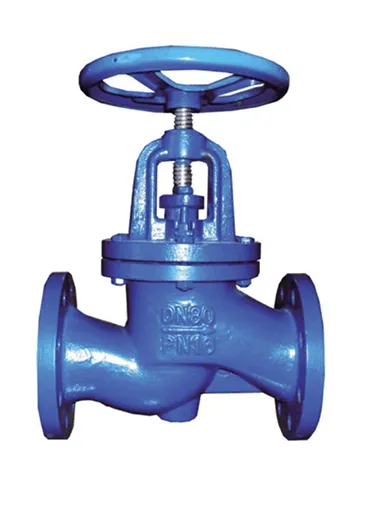

DIN Resilient Seat Gate Valve NRS

In the domain of industrial valves, the socket and resilient seat gate valve stands out as a crucial component for a variety of piping systems. Engineered to deliver exceptional control and efficiency, these valves have become indispensable in sectors ranging from water distribution to process industries. Their primary function is to allow or obstruct fluid flow, ensuring optimal performance of the entire network.

Authoritativeness in the valve manufacturing sector comes from adhering to stringent international standards. Leading manufacturers of socket and resilient seat gate valves ensure conformity to ISO and API standards, reinforcing their commitment to quality and performance. The reputation of these manufacturers hinges on their ability to deliver products that consistently meet and exceed customer expectations. Trustworthiness is further cemented by comprehensive after-sales support and warranty assurances provided by reputable valve suppliers. This service dimension ensures users feel secure in their investment, knowing that professional support is just a call away should any issue arise. Feedback from industry veterans points to a preference for brands that offer extensive documentation and training resources, enabling operators to maximize the utility of their socket and resilient seat gate valves. In product realms where reliability and efficiency are non-negotiable, the socket and resilient seat gate valve emerges as a frontrunner. Its seamless integration, robust sealing capability, and alignment with global standards make it an imperative choice for industries aiming to enhance their operational excellence. As technology advances, continuous innovation in material science and valve design will likely propel the functionality and adoption of these valves even further, securing their place as an industry staple for years to come.

Authoritativeness in the valve manufacturing sector comes from adhering to stringent international standards. Leading manufacturers of socket and resilient seat gate valves ensure conformity to ISO and API standards, reinforcing their commitment to quality and performance. The reputation of these manufacturers hinges on their ability to deliver products that consistently meet and exceed customer expectations. Trustworthiness is further cemented by comprehensive after-sales support and warranty assurances provided by reputable valve suppliers. This service dimension ensures users feel secure in their investment, knowing that professional support is just a call away should any issue arise. Feedback from industry veterans points to a preference for brands that offer extensive documentation and training resources, enabling operators to maximize the utility of their socket and resilient seat gate valves. In product realms where reliability and efficiency are non-negotiable, the socket and resilient seat gate valve emerges as a frontrunner. Its seamless integration, robust sealing capability, and alignment with global standards make it an imperative choice for industries aiming to enhance their operational excellence. As technology advances, continuous innovation in material science and valve design will likely propel the functionality and adoption of these valves even further, securing their place as an industry staple for years to come.

Share

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025