Dec . 18, 2024 10:51 Back to list

victaulic butterfly valve

Understanding Victaulic Butterfly Valves A Comprehensive Overview

Victaulic butterfly valves have emerged as a pivotal solution in modern piping systems, providing efficiency, reliability, and ease of use across various industrial applications. Known for their distinctive design and versatile functionality, these valves are particularly favored in industries ranging from chemical processing to water treatment and HVAC systems.

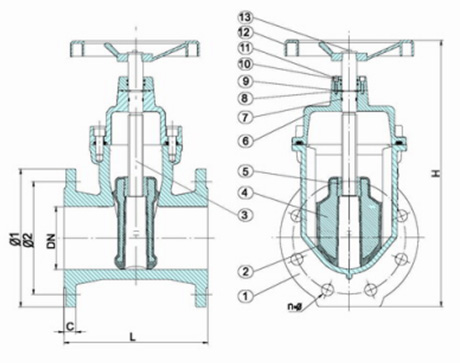

Design and Construction

At the core of the Victaulic butterfly valve's functionality is its simple yet effective design. The valve consists of a disc that rotates around a central axis, allowing for quick opening and closing operations. This design is complemented by a body that typically features a resilient elastomeric seat, which ensures a tight seal and minimizes leakage. Victaulic's innovative approach to manufacturing combines high-quality materials, such as ductile iron or stainless steel, with precision engineering to produce valves that can withstand harsh conditions and high pressures.

Advantages of Victaulic Butterfly Valves

1. Space Efficiency One of the most significant advantages of butterfly valves is their compact size. Compared to gate or ball valves, they require less space, making them an ideal choice for installations where space is at a premium.

2. Quick Operation Butterfly valves provide rapid operation due to their quarter-turn mechanism. This feature is essential in applications that require prompt shut-off and flow control, enhancing the overall efficiency of the system.

3. Versatility Victaulic butterfly valves are suitable for various media, including water, gas, and even slurries. Their ability to handle different fluid types makes them a versatile choice for multiple applications, from fire protection systems to industrial processing.

4. Low Maintenance The simple design of butterfly valves leads to reduced wear and tear, requiring less maintenance over time. Their robust construction minimizes the need for frequent replacements, resulting in cost savings for organizations.

victaulic butterfly valve

5. Flow Control Butterfly valves are exceptional for handling large volumes of fluid with relatively low pressure drop. This characteristic makes them perfect for applications where maintaining flow rate efficiency is crucial.

Applications of Victaulic Butterfly Valves

Victaulic butterfly valves are widely used in various sectors, including

- Water and Wastewater Treatment In these applications, the valves are integral for controlling the flow of water and effluent materials, ensuring proper treatment processes.

- HVAC Systems In heating, ventilation, and air conditioning systems, these valves help manage airflow and maintain desired temperature conditions, contributing to energy efficiency.

- Chemical Processing Their robust materials and design make Victaulic butterfly valves ideal for handling corrosive liquids and gases in chemical plants.

- Fire Protection Systems They are often employed in fire protection systems for controlling water flow in sprinkler systems, ensuring rapid response during fire emergencies.

Conclusion

Victaulic butterfly valves stand out as a reliable choice for industries requiring efficient flow control solutions. Their innovative design, coupled with significant advantages such as space efficiency, quick operation, and versatility, makes them an excellent option for various applications. As industries continue to evolve and demand more efficient and reliable systems, the role of butterfly valves, particularly those manufactured by Victaulic, is likely to become even more pronounced. Investing in quality butterfly valves not only enhances operational efficiency but also reinforces the safety and reliability of fluid handling systems. With their proven benefits and applications, Victaulic butterfly valves represent a smart investment for future-ready infrastructure.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025