Nov . 16, 2024 07:39 Back to list

trunnion mounted

Understanding Trunnion Mounted Equipment Applications and Benefits

Trunnion mounted devices have gained significant traction in various industries due to their unique design and functionality. In essence, a trunnion mount is a bearing surface that allows for oscillation and rotation in multiple directions while maintaining stability. This engineering concept is widely used in various applications, particularly in the fields of materials handling, mining, and fluid dynamics.

One of the primary advantages of trunnion mounted systems is their ability to accommodate heavy loads while providing a smooth range of motion. This feature is especially beneficial in industrial settings where heavy machinery and equipment must operate efficiently. For instance, in the mining sector, trunnion mounted structures are commonly employed in ore processing equipment, conveyor systems, and mining machinery. The robust design of trunnion mounts allows for adjustments and adaptations, ensuring smooth operational flow even under challenging conditions.

Enhanced Stability and Load Distribution

Another significant benefit of trunnion mounts is their impressive stability and load distribution capabilities. Unlike conventional mounting systems, which may lead to uneven wear and tear or instability during operation, trunnion mounts evenly distribute weight across the fixture. This characteristic not only prolongs the lifespan of the equipment but also enhances safety. By reducing the likelihood of unexpected shifts or failures, operators can focus on task efficiency without compromising safety.

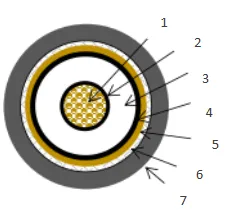

Trunnion mounted valves and fittings are particularly noteworthy in the fluid dynamics sector. These components allow for seamless flow control in systems handling various liquids and gases. The ability to rotate freely around a central axis enables operators to change the flow directions easily, providing flexibility in design and operation. Whether in oil rigs or chemical processing plants, trunnion mounted valves ensure precise flow management, minimizing the risk of leaks or blockages that could lead to safety hazards or costly downtime.

trunnion mounted

Applications Across Industries

The versatility of trunnion mounted systems extends across many other industries. In construction, for example, they find applications in cranes and other heavy lifting equipment. The trunnion design allows for easy maneuverability while maintaining structural integrity, crucial for lifting heavy loads at various angles. Similarly, in the agricultural sector, trunnion mounted attachments are utilized in equipment like seeders and tillers, where they improve the functionality and efficiency of field operations.

Moreover, the automotive industry benefits from trunnion mounted components in suspension systems and steering mechanisms, improving vehicle handling and performance. The design's robustness allows vehicles to navigate diverse terrains more effectively, enhancing stability and ride comfort.

Conclusion

In summary, trunnion mounted systems play a critical role in modern machinery across various industries, from mining and construction to agriculture and automotive applications. Their unique design allows for dynamic movement and load-bearing capabilities while maintaining balance and stability. As industries continue to evolve and require more sophisticated machinery, the demand for trunnion mounted equipment will likely increase. By understanding their benefits and applications, companies can make informed decisions to enhance operational efficiency, safety, and overall productivity in their respective fields. Whether you are a business owner, an engineer, or an operator, recognizing the importance of trunnion mounted systems could provide a significant advantage in achieving optimal performance in industrial applications.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025