Nov . 25, 2024 14:56 Back to list

Durable Stainless Steel Ball Check Valve for Reliable Fluid Control Solutions

Stainless Steel Ball Check Valve An Overview

Stainless steel ball check valves are essential components in fluid control systems, providing reliable one-way flow regulation to prevent backflow within pipelines. Their design is based on the simple yet effective mechanism of a ball that moves to seal the valve seat under the influence of gravity or fluid pressure, ensuring that the medium flows in the desired direction. This article explores the features, advantages, applications, and considerations associated with stainless steel ball check valves.

Design and Functionality

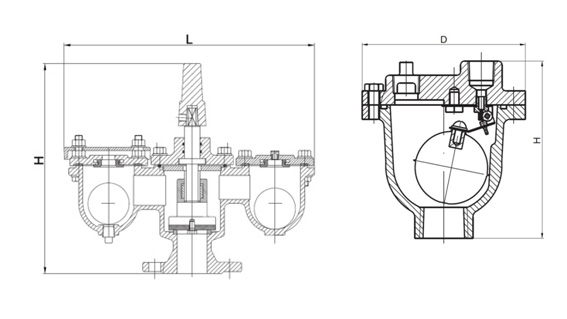

The stainless steel ball check valve comprises a valve body, a ball, and a seat. The ball is typically made of stainless steel or a similar corrosion-resistant material, allowing it to withstand harsh environments. When fluid flows in the correct direction, it forces the ball away from the seat, allowing the medium to pass through. Conversely, when back pressure occurs, the ball is pushed back onto the seat, effectively sealing the valve and preventing reverse flow.

The design of the ball check valve ensures minimal pressure drop during operation, making it suitable for various applications. The materials used in its construction contribute to its durability, resistance to corrosion, and ability to handle different temperatures and pressures, which is crucial in industrial applications.

Advantages of Stainless Steel Ball Check Valves

2. Durability The robust design and high-quality materials used in stainless steel ball check valves ensure a long service life, reducing the need for frequent replacements and lowering maintenance costs.

3. Low Maintenance With fewer moving parts compared to other types of check valves, stainless steel ball check valves require minimal maintenance, which is advantageous for operators looking to reduce downtime.

4. Versatile Applications These valves are widely used across various industries, including oil and gas, pharmaceuticals, and manufacturing. Their versatility allows for use in different systems, from simple domestic plumbing to complex industrial processes.

stainless steel ball check valve

5. Streamlined Flow The spherical design of the valve promotes smooth flow with minimal turbulence, which is critical in applications where flow efficiency is paramount.

Applications

Stainless steel ball check valves are utilized in numerous settings, including

- Pumping Systems They prevent backflow in pump discharge lines, ensuring that the system operates efficiently without risking damage to pumps and equipment. - HVAC Systems In heating, ventilation, and air conditioning applications, these valves help manage flow and maintain system stability. - Water Treatment In water treatment facilities, ball check valves are used to control the flow of treated water and prevent contamination.

Considerations

When selecting stainless steel ball check valves, several factors should be considered

- Size and Pressure Rating It is crucial to choose a valve size and pressure rating that align with the specific requirements of the system to ensure optimal performance. - Material Compatibility While stainless steel is highly resistant to corrosion, it is essential to verify that the material is compatible with the fluids being transported, especially in chemical applications. - Installation Orientation Ball check valves can usually be installed in any orientation, but vertical installations may yield different performance results compared to horizontal setups.

Conclusion

Stainless steel ball check valves play a significant role in ensuring the efficient and safe operation of fluid systems across various industries. Their durable construction, corrosion resistance, and low maintenance requirements make them a preferred choice for many applications. By understanding their features and benefits, engineers and operators can make informed decisions when integrating these valves into their systems, ultimately enhancing performance and reliability.

Share

-

Y Strainers: Protecting Your Pipes with PrecisionNewsAug.27,2025

-

Wafer Type Butterfly Valves: Reliable Flow Control SolutionsNewsAug.27,2025

-

Wafer Type Butterfly Valves: Essential Components for Efficient Flow ControlNewsAug.27,2025

-

Reliable Flow Control with High-Quality Check ValvesNewsAug.27,2025

-

Reliable Flow Control with Gate ValvesNewsAug.27,2025

-

Innovative Check Valves for Reliable Flow ControlNewsAug.27,2025