Nov . 10, 2024 13:38 Back to list

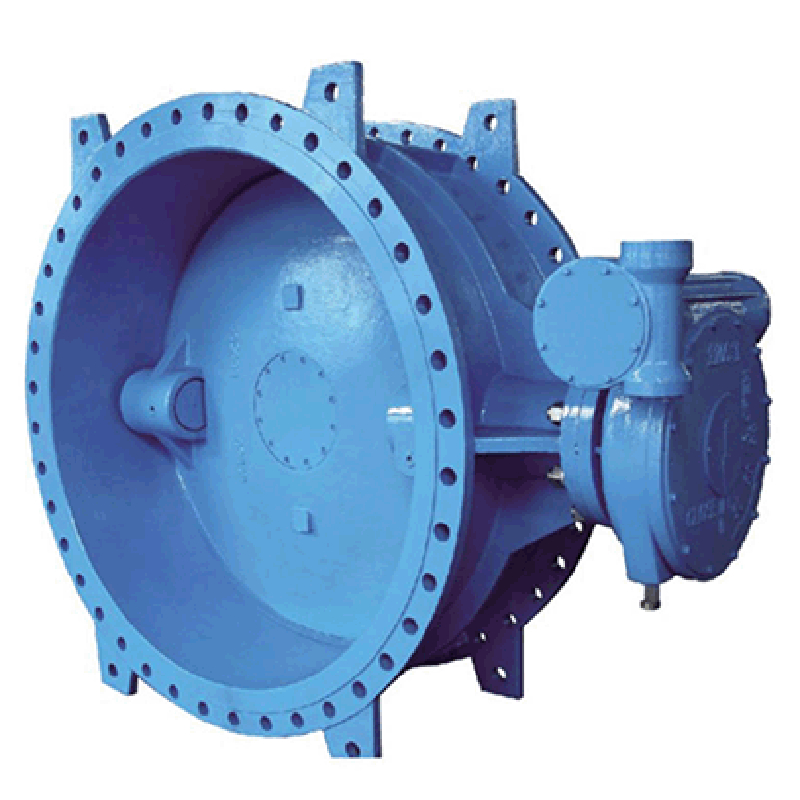

Grooved End Butterfly Valve for Efficient Flow Control Solutions in Piping Systems

Understanding Grooved End Butterfly Valves Features and Applications

Grooved end butterfly valves are essential components in various industrial applications, designed to regulate the flow of liquids or gases in piping systems. Known for their compact size and lightweight structure, these valves boast several advantages over traditional flanged or threaded options. This article explores the features, benefits, and applications of grooved end butterfly valves.

What is a Grooved End Butterfly Valve?

A grooved end butterfly valve features a disc that rotates around a central axis, allowing it to either fully open or close, thereby regulating flow. The grooved end design refers to the valve's connection method. Instead of traditional flanges, these valves are fitted with grooves that enable quick and easy installation and removal. This makes them an ideal choice for maintenance-friendly systems.

Key Features

1. Design and Construction The cylindrical body of the valve is designed to reduce turbulence in the flow, ensuring efficient performance. Made from durable materials such as stainless steel, ductile iron, or PVC, grooved end butterfly valves exhibit resistance to corrosion and wear.

2. Operating Mechanism The valve operates with a simple rotating mechanism, controlled manually or automatically. This simplicity minimizes potential points of failure, enhancing reliability and ease of use.

3. Space Efficiency Unlike larger valve types, grooved end butterfly valves occupy minimal space within a piping system. Their design allows for a more streamlined arrangement, which is especially useful in areas where space is limited.

Advantages of Grooved End Butterfly Valves

1. Quick Installation The grooved end connection simplifies installation. With the use of compatible grooved fittings, these valves can be easily integrated into existing piping systems without the need for extensive modifications or additional components.

grooved end butterfly valve

2. Versatility These valves are suitable for a wide range of applications, including HVAC systems, water treatment plants, chemical processing facilities, and fire protection systems. Their versatility makes them a popular choice across diverse industries.

3. Cost-Effectiveness The straightforward design translates into lower manufacturing costs, which benefits end-users by offering a high-quality product at a competitive price point.

4. Maintenance The simplicity of the butterfly valve design allows for easy inspection, cleaning, and maintenance. The ability to access the valve without needing to disassemble large portions of the pipework saves time and reduces labor costs.

Applications in Various Industries

Grooved end butterfly valves find widespread use in numerous sectors

- Water and Wastewater Treatment The ability to manage flow and pressure effectively makes these valves vital for controlling water distribution and effluent discharge processes.

- HVAC Systems They play a crucial role in regulating the flow of fluids in heating and cooling systems, ensuring efficient thermal management.

- Chemical Processing The durability and chemical resistance of grooved end butterfly valves make them ideal for handling various corrosive substances in chemical manufacturing.

- Fire Protection Systems In municipal and industrial fire systems, these valves help manage water supply for firefighting operations, providing a reliable action in critical situations.

Conclusion

Grooved end butterfly valves represent an efficient, reliable, and cost-effective solution for fluid control in diverse applications. Their unique design and numerous advantages ensure that they continue to be a favored choice across multiple industries. Understanding their features and benefits can help in making informed decisions for system installations and upgrades, ultimately contributing to enhanced operational efficiency and durability.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025