Dec . 25, 2024 10:40 Back to list

galvanized rubber expansion joint

Understanding Galvanized Rubber Expansion Joints A Key Component in Modern Engineering

In the realm of engineering and construction, the need for effective solutions to manage movement and flexibility in piping systems is paramount. One such solution is the galvanized rubber expansion joint. This component plays a crucial role in accommodating vibrations, thermal expansion, and misalignment in various industrial applications, ensuring both efficiency and durability. This article delves into the features, benefits, and common applications of galvanized rubber expansion joints.

What is a Galvanized Rubber Expansion Joint?

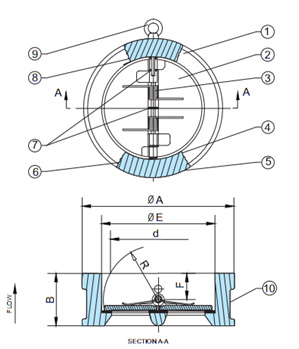

A galvanized rubber expansion joint is an engineered coupling that connects two sections of piping while allowing for the absorption of movement. It typically consists of a rubber body reinforced with fabric or steel, providing excellent flexibility and resilience. The term galvanized refers to the coating of the metal components—often steel—that protects against corrosion, thereby extending the lifespan of the joint.

These expansion joints can be found in various shapes, including single and double arch designs, depending on the specific requirements of the application. The combination of rubber and galvanized metal makes these joints particularly adept at handling the stresses associated with thermal expansion, contraction, and mechanical vibrations.

Benefits of Galvanized Rubber Expansion Joints

1. Flexibility and Movement Accommodation Galvanized rubber expansion joints are designed to absorb movement in piping systems due to thermal expansion and contraction. This flexibility helps prevent stress on the pipeline, reducing the risk of cracks and leaks, which can lead to costly repairs and downtime.

2. Vibration Damping In many industrial environments, machinery generates vibrations that can propagate through piping systems. Rubber expansion joints significantly dampen these vibrations, protecting both the pipeline and connected equipment from damage.

4. Ease of Installation These joints are relatively easy to install compared to traditional rigid pipe connections. Their design allows for quick integration into existing systems, minimizing downtime during installation.

galvanized rubber expansion joint

5. Cost-Effectiveness By reducing the likelihood of pipeline failures and the need for frequent maintenance, galvanized rubber expansion joints can be a cost-effective solution in the long term.

Applications of Galvanized Rubber Expansion Joints

Galvanized rubber expansion joints find extensive usage in a variety of industries due to their versatility

- Water and Wastewater Treatment In facilities managing water treatment processes, these expansion joints help accommodate flow changes and thermal fluctuations, ensuring system integrity. - HVAC Systems In heating, ventilation, and air conditioning systems, they mitigate vibrations caused by mechanical systems, contributing to smoother operation and improved air quality.

- Oil and Gas The oil and gas industry often necessitates robust flexible connections in pipelines transporting crude oil and natural gas. Galvanized rubber expansion joints manage thermal expansion and contraction, enhancing system safety.

- Chemical Processing Many chemicals can be corrosive to standard materials. The protective galvanized coating, paired with the inherent properties of rubber, makes these joints ideal for use in chemical processing facilities.

- Power Generation In power generation plants, especially in steam and gas applications, managing thermal changes is critical. These expansion joints help maintain operational efficiency and reliability.

Conclusion

In summary, galvanized rubber expansion joints are a vital component in contemporary piping systems, providing flexibility, vibration dampening, and corrosion resistance. Their various applications across industries demonstrate their essential role in maintaining system integrity and efficiency. By understanding the importance of these components, engineers and operators can make informed decisions that enhance the performance and longevity of their systems. As industries continue to evolve, the reliance on reliable and effective solutions like galvanized rubber expansion joints will undoubtedly remain a key consideration in engineering practices.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025