Feb . 05, 2025 05:08 Back to list

Ball Check Valve

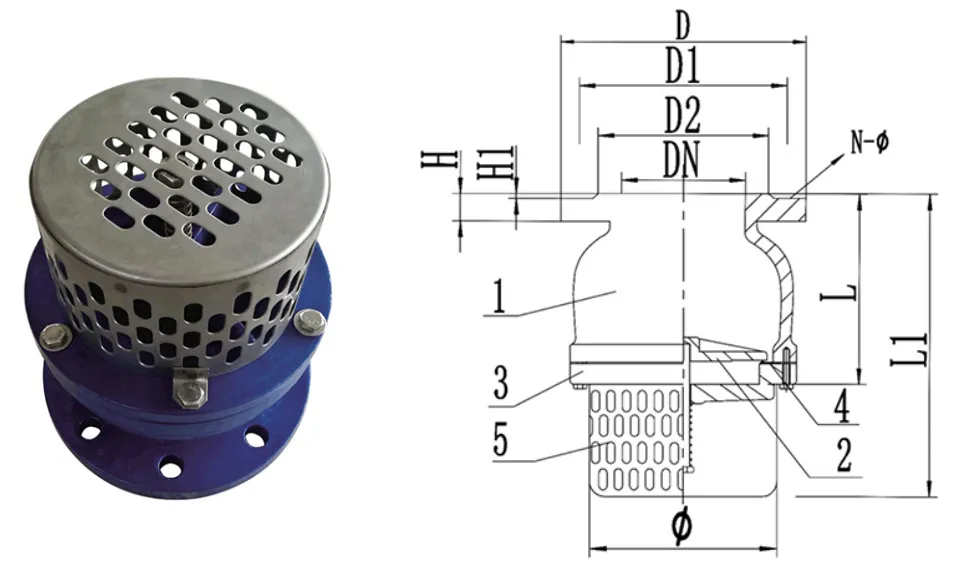

Foot valves with strainers are essential components in a vast array of industrial and commercial systems, playing a crucial role in maintaining operational efficiency and ensuring system longevity. These devices are especially beneficial in systems that draw fluids from tanks, wells, or reservoirs, providing a safeguard against contamination and maximizing flow efficiency.

Authoritativeness in the industry often comes from understanding and adhering to regulations and standards that govern the use of foot valves and strainers. Compliance with standards such as ANSI and API ensures the components meet necessary safety and quality benchmarks. Manufacturers with certifications from bodies like ISO provide an added layer of assurance to end-users, emphasizing the component's reliability and performance. Trustworthiness in this domain is also built on the reputations of suppliers and manufacturers. Companies that provide foot valves with strainers often offer certification documentation and performance data to back their claims. Reviews and case studies from peers in the industry can also be invaluable, providing insight into real-world performance and reliability issues. In practical application, maintenance of these components is a straightforward process but one that should not be overlooked. Regular inspection of the strainer is necessary to prevent build-up of debris which could impede flow or damage the pump. Simple cleaning procedures, such as backflushing or removal for manual cleaning, can extend the component’s lifespan significantly. Furthermore, the sealing mechanism within the foot valve should be checked periodically to ensure it is free of wear or damage that might compromise its function. In conclusion, foot valves with strainers are an indispensable investment in fluid management systems, offering protection against contaminants and preventing costly downtime due to pump failure or system blockages. By leveraging the expertise of seasoned professionals when choosing and maintaining these components, operators can enhance system efficiency and longevity, ensuring seamless operations across a myriad of industrial applications.

Authoritativeness in the industry often comes from understanding and adhering to regulations and standards that govern the use of foot valves and strainers. Compliance with standards such as ANSI and API ensures the components meet necessary safety and quality benchmarks. Manufacturers with certifications from bodies like ISO provide an added layer of assurance to end-users, emphasizing the component's reliability and performance. Trustworthiness in this domain is also built on the reputations of suppliers and manufacturers. Companies that provide foot valves with strainers often offer certification documentation and performance data to back their claims. Reviews and case studies from peers in the industry can also be invaluable, providing insight into real-world performance and reliability issues. In practical application, maintenance of these components is a straightforward process but one that should not be overlooked. Regular inspection of the strainer is necessary to prevent build-up of debris which could impede flow or damage the pump. Simple cleaning procedures, such as backflushing or removal for manual cleaning, can extend the component’s lifespan significantly. Furthermore, the sealing mechanism within the foot valve should be checked periodically to ensure it is free of wear or damage that might compromise its function. In conclusion, foot valves with strainers are an indispensable investment in fluid management systems, offering protection against contaminants and preventing costly downtime due to pump failure or system blockages. By leveraging the expertise of seasoned professionals when choosing and maintaining these components, operators can enhance system efficiency and longevity, ensuring seamless operations across a myriad of industrial applications.

Share

Prev:

Next:

Latest news

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025