Nov . 23, 2024 05:34 Back to list

ductile iron butterfly valve

The Advantages of Ductile Iron Butterfly Valves in Industrial Applications

Ductile iron butterfly valves have become a key component in various industrial applications, notably in the sectors of water treatment, oil and gas, and chemical processing. Their unique combination of properties, including strength, durability, and corrosion resistance, makes them an ideal choice for regulating flow in pipelines.

Understanding Ductile Iron

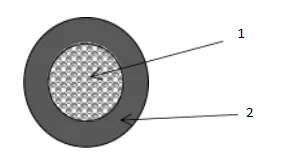

Ductile iron, also known as nodular cast iron, is a type of cast iron that possesses enhanced mechanical properties compared to traditional cast iron. It is characterized by its spherical graphite microstructure, which provides improved ductility and tensile strength. This allows ductile iron butterfly valves to withstand higher pressure and temperature variations, making them suitable for high-demand industrial environments.

Design and Functionality

Butterfly valves are named for their disc closure mechanism, which resembles the wings of a butterfly. The disc pivots around a central shaft, allowing for quick and efficient flow control. Ductile iron butterfly valves come in various sizes and configurations, including lug-style and wafer-style designs. The versatility in design makes them adaptable to different types of piping systems.

One of the main advantages of butterfly valves is their lightweight, compact design. Unlike gate valves or globe valves, butterfly valves require less space and can be installed in tight locations. Moreover, they provide a reliable sealing mechanism, preventing leaks and ensuring efficient operation.

Corrosion Resistance

ductile iron butterfly valve

In many industrial settings, valves are exposed to harsh environments and corrosive substances. Ductile iron butterfly valves often come with protective coatings such as epoxy or ceramic, enhancing their resistance to corrosion and extending their lifespan. This characteristic is particularly crucial in water treatment facilities, where valves must be resistant to aggressive chemicals and varying pH levels.

Cost-Effectiveness

Another significant advantage of ductile iron butterfly valves is their cost-effectiveness. While the initial investment may be higher than some other materials, their longer lifespan and lower maintenance requirements often lead to reduced overall costs. Organizations can benefit from fewer replacements and downtime, which ultimately improves operational efficiency.

Environmental Impact

Ductile iron butterfly valves also contribute to environmentally sustainable practices. Their ability to create a tight seal reduces the risk of leaks, which is vital in preventing contamination of natural resources. Additionally, the durability of these valves means they do not need to be replaced as frequently, resulting in less waste and fewer materials being used over time.

Conclusion

In summary, ductile iron butterfly valves are an excellent choice for various industrial applications due to their remarkable strength, durability, and resistance to corrosion. Their lightweight design, cost-effectiveness, and environmental advantages make them a preferred option among engineers and facility managers. As industries continue to grow and evolve, the role of ductile iron butterfly valves in enhancing efficiency and sustainability cannot be understated. Investing in high-quality butterfly valves can lead to smoother operations and improved long-term outcomes for any industrial application.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025