Dec . 10, 2024 11:11 Back to list

double ball rubber joint factory

The Importance of Double Ball Rubber Joint Factories in Modern Engineering

In the realm of modern engineering and industrial design, one component that stands out for its effectiveness and versatility is the double ball rubber joint. These joints are critical in various applications, ranging from piping systems to automotive engineering, providing flexibility and accommodating movements while ensuring durability and leak-proofing. The factories that produce these components play a significant role in maintaining the efficiency and reliability of different systems.

Understanding Double Ball Rubber Joints

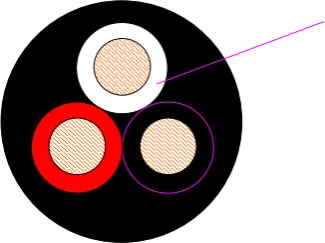

Double ball rubber joints, also known as rubber expansion joints or flexible joints, are designed to absorb vibrations and movements within piping and machinery. They consist of a rubber body shaped like a ball that connects at two ends with flanges or pipes. This unique design allows for multidirectional flexibility, which is essential in systems where temperature changes, pressure fluctuations, or mechanical movement occur.

These joints come in various sizes and specifications, tailored to meet the distinct needs of each application. The materials utilized can vary, with options like natural rubber or specialized compounds designed to withstand harsh environments, chemicals, or extreme temperatures. The ability to customize these joints makes them invaluable for engineers looking to optimize system performance.

The Role of Manufacturing Factories

The production of double ball rubber joints requires precision and expertise. Factories that specialize in their manufacturing ensure that high-quality materials are used and that strict quality control measures are implemented throughout the production process. This is crucial because the failure of a rubber joint can lead to severe consequences such as leaks, system failures, or even catastrophic accidents in critical industries like oil and gas, water treatment, and power generation.

double ball rubber joint factory

Typically, a factory's process begins with the careful selection of raw materials, which may undergo tests for durability and flexibility. Manufacturing technology, including molding and curing processes, is pivotal in determining the final product's performance. Advanced machinery operates under rigorous standards, ensuring that each rubber joint can withstand the stresses it will encounter in real-world applications.

Moreover, many double ball rubber joint factories focus on research and development to innovate new products. This includes enhancing existing designs to improve lifespan and resistance to operational hazards. By investing in R&D, these factories help drive advancements in engineering solutions, facilitating the implementation of safer and more efficient systems across various sectors.

Quality Assurance and Compliance

Quality assurance is the backbone of any reputable double ball rubber joint factory. Manufacturers must adhere to industry standards and regulations, which often involve certifications such as ISO or ASTM. Compliance with these standards ensures that products are not only effective but also safe for use in critical applications.

Routine inspections and testing—including compression tests, aging tests, and performance assessments—are essential components of the manufacturing process. Factories employ skilled technicians and engineers who evaluate these joints to confirm they meet the necessary requirements before they are sent to the market.

Conclusion

In conclusion, double ball rubber joint factories play an indispensable role in supporting modern engineering applications. Through their commitment to quality, innovation, and compliance, they ensure that these essential components meet the demands of various industries. As industries continue to evolve and seek more efficient solutions, the importance of these factories will only grow, driving advancements that will shape the future of engineering and manufacturing. Whether in construction, automotive, or infrastructure, the double ball rubber joint is a pivotal element in the reliability and success of countless systems worldwide.

Share

-

Reliable Wafer Type Butterfly Valves for Every IndustryNewsJul.25,2025

-

Reliable Flow Control Begins with the Right Ball Check ValveNewsJul.25,2025

-

Precision Flow Control Starts with Quality ValvesNewsJul.25,2025

-

Industrial Flow Control ReliabilityNewsJul.25,2025

-

Engineered for Efficiency Gate Valves That Power Industrial PerformanceNewsJul.25,2025

-

Empowering Infrastructure Through Quality ManufacturingNewsJul.25,2025